Polyether type moisture-curable polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive, moisture curing technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of easy quality fluctuation, long dehydration time, complex production process, etc. Molecular weight and distribution stability, good initial and final viscosity, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

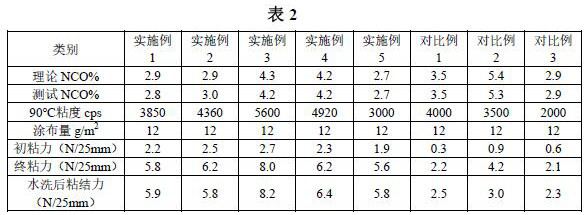

Examples

Embodiment 1

[0054] Under a nitrogen atmosphere, add MDI-100 into the reactor, start stirring, control the reaction temperature at 65°C, add a polymerization inhibitor, after stirring evenly, control the temperature of the reactor at 85°C, and slowly add polyether, catalyst, and disinfectant in sequence. The foaming agent is reacted, and after 120 minutes, the defoaming treatment is carried out, and the reaction is completed after 60 minutes, and the NCO content is tested to meet the design requirements, and the material is discharged.

Embodiment 2

[0056] Under a nitrogen atmosphere, add MDI-50 to the reactor, start stirring, control the reaction temperature to 68°C, add a polymerization inhibitor, stir well, then slowly add polyether, catalyst, and defoamer to react, control the reactor The temperature is 86°C, after 120 minutes, defoaming treatment is carried out, and the reaction is completed after 60 minutes, and the NCO content is tested to meet the design requirements, and the material is discharged.

Embodiment 3

[0058] Under a nitrogen atmosphere, add MDI-100 to the reactor, start stirring, control the reaction temperature to 70°C, add a polymerization inhibitor, stir well, then slowly add polyether, catalyst, and defoamer to react, control the reactor The temperature is 90°C, defoaming treatment is carried out after 120 minutes, and the reaction is completed after 60 minutes, and the NCO content is tested to meet the design requirements, and the material is discharged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com