Reactive polyurethane hot melt adhesive with ultrahigh initial adhesion strength and preparation method thereof

A polyurethane hot-melt adhesive, reactive technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of long process time, multi-pressure holding tools, etc. good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

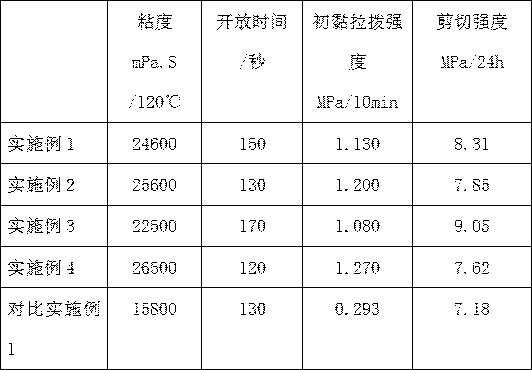

Examples

Embodiment 1

[0030] Heat the reactor to a constant temperature of 140°C, add 28 parts of crystalline polyester POL-A3500, 45 parts of liquid polyester CP-2070, and 11 parts of thermoplastic copolyester Dynacoll S 1401 and mix well in the stirred tank. Under the condition of full vacuum, stir and dehydrate for 2 hours until the moisture content of the raw materials in the kettle is lower than 250ppm, and then fill with dry nitrogen to break the vacuum. Lower the temperature to 130°C in a nitrogen atmosphere, add 15 parts of Wanhua's pure MDI100, stir quickly and evenly, control the temperature at 130°C and stir for 50 minutes under full vacuum. Fill with nitrogen to break the vacuum, lower the temperature to 120°C, add 0.3 parts of dibutyltin dilaurate, 0.5 parts of KH560, and 0.3 parts of BYK-361N and stir in full vacuum for 1 hour. Nitrogen is filled to break the vacuum, the material is discharged at a constant temperature of 120°C, and the package is sealed to obtain a reactive polyureth...

Embodiment 2

[0032] Heat the reactor to a constant temperature of 140°C, add 24 parts of crystalline polyester POL-A3500, 6 parts of liquid polyester POL-7112, 38 parts of liquid polyester POL-656, and 11 parts of thermoplastic copolyester Dynacoll S 1401 and 6 parts of Sylvalite RE were mixed evenly in a 100L stirred tank, and stirred and dehydrated at 140°C for 2 hours under full vacuum until the moisture content of the raw materials in the tank was lower than 250ppm, and then filled with dry nitrogen to break the vacuum. Lower the temperature to 130°C in a nitrogen atmosphere, add 13 parts of Wanhua's pure MDI100, stir quickly and evenly, control the temperature at 130°C and stir for 50 minutes under full vacuum. Fill with nitrogen to break the vacuum, lower the temperature to 120°C, add 0.3 parts of triethylenediamine, 0.5 parts of KH570, and 0.3 parts of BYK-361N and stir in full vacuum for 1 hour. Nitrogen is filled to break the vacuum, the material is discharged at a constant temper...

Embodiment 3

[0034] Heat the reactor to a constant temperature of 140°C, add 23 parts of crystalline polyester Hoocker F-931, 10 parts of liquid polyester CP-2110, 37 parts of liquid polyester CP-2056, and 7 parts of thermoplastic copolyester Dynacoll Mix S 1402 and 6 parts of Sylvares TP 2040 in a stirred kettle evenly, and stir and dehydrate at 140°C for 2 hours under full vacuum until the moisture content of the raw materials in the kettle is lower than 250ppm, and then fill with dry nitrogen to break the vacuum. Lower the temperature to 130°C in a nitrogen atmosphere, add 16 parts of pure MDI100 from Wanhua, stir quickly and evenly, control the temperature at 130°C and stir for 50 minutes under full vacuum. Fill with nitrogen to break the vacuum, lower the temperature to 120°C, add 0.3 part of triethylenediamine, 0.8 part of KH590, 0.1 part of BYK-361N and stir for 1 hour under full vacuum. Nitrogen is filled to break the vacuum, the material is discharged at a constant temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com