Graphite negative electrode material and preparation method and application thereof

A graphite negative electrode and graphite material technology, applied in the direction of graphite, negative electrodes, chemical instruments and methods, etc., can solve problems such as poor economy, adverse effects on processing performance, technical bottlenecks in improving effects, etc., and achieve enhanced stability and high initial viscosity and peel strength, good modification or coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

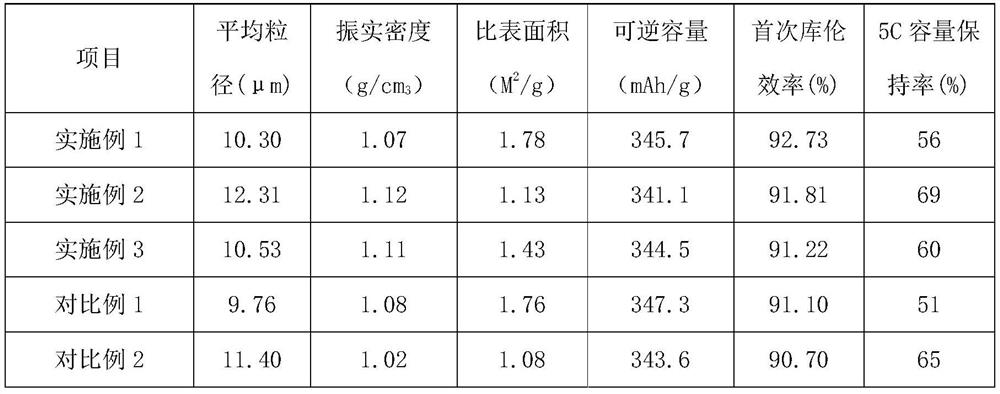

Embodiment 1

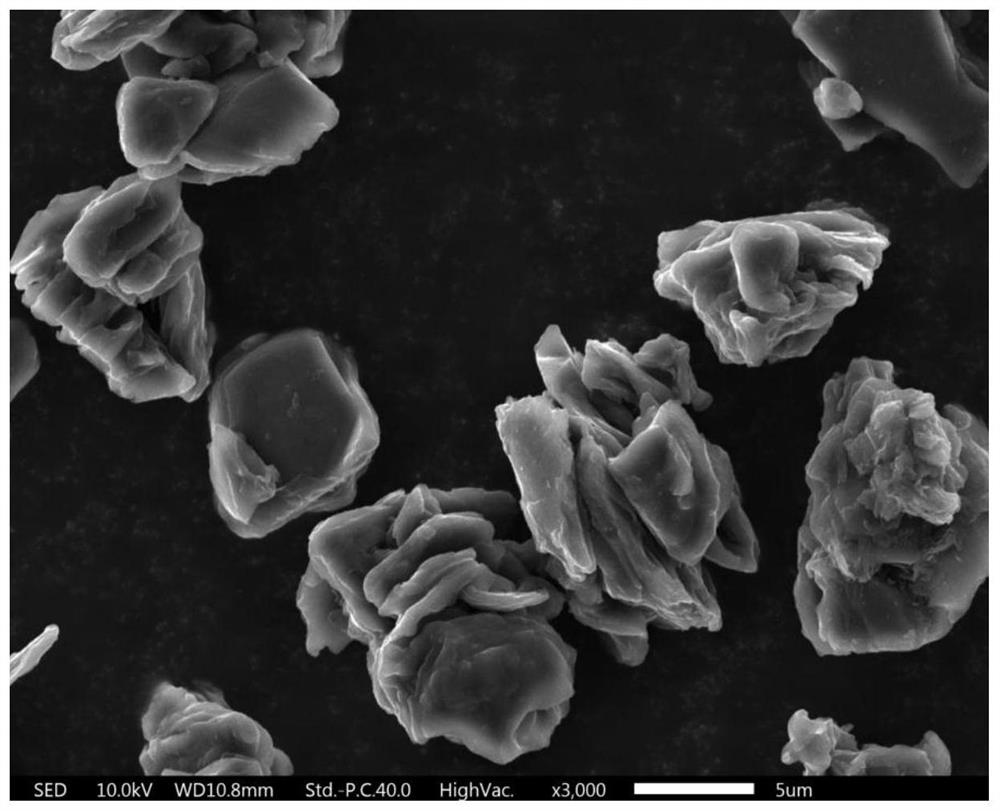

[0035] A preparation method of a graphite negative electrode material, comprising the following preparation steps:

[0036] S1: Raw material micronization treatment; mechanically pulverize the artificial graphite material to obtain raw material powder with an average particle size of 8.0-11 μm;

[0037] S2: Modification heat treatment: Premix the raw material powder in step S1 with traditional asphaltene auxiliary materials (softening point 120-180°C), and viscosifying modified coating agent according to the weight ratio of 90:8:2 to make them uniformly dispersed, Then put the mixed material into a horizontal kettle for heat treatment, the treatment temperature is 750°C, the equipment rotation frequency is 50HZ, and the heat treatment material is obtained;

[0038] S3: Particle regularization treatment; the heat-treated material obtained in step S2 is subjected to particle shaping treatment, and the particle morphology is further controlled and modified by equipment mechanical...

Embodiment 2

[0043]A preparation method of a graphite negative electrode material, comprising the following preparation steps:

[0044] S1: Raw material micronization treatment; mechanically pulverize the artificial graphite material to obtain raw material powder with an average particle size of 8.0-11 μm;

[0045] S2: Modification heat treatment: pre-mix the raw material powder in step S1 with traditional asphaltene auxiliary materials (softening point 120-180°C) at a weight ratio of 90:10 to make them evenly dispersed, and then put the mixed materials into a horizontal kettle for heat treatment , the treatment temperature is 750°C, and the rotation frequency of the equipment is 50HZ to obtain heat-treated materials;

[0046] S3: Particle regularization treatment; the heat-treated material obtained in step S2 is subjected to particle shaping treatment, and the particle morphology is further controlled and modified by equipment mechanical impact or shear force to obtain a regularized mater...

Embodiment 3

[0051] A preparation method of a graphite negative electrode material, comprising the following preparation steps:

[0052] S1: Raw material micronization treatment; mechanically pulverize the artificial graphite material to obtain raw material powder with an average particle size of 8.0-11 μm;

[0053] S2: Modification heat treatment: Premix the raw material powder in step S1 with traditional asphaltene auxiliary materials (softening point 120-180°C), and viscosifying modified coating agent according to the weight ratio of 90:8:2 to make them uniformly dispersed, Then put the mixed material into a horizontal kettle for heat treatment, the treatment temperature is 750°C, the equipment rotation frequency is 50HZ, and the heat treatment material is obtained;

[0054] S3: Particle regularization treatment; the heat-treated material obtained in step S2 is subjected to particle shaping treatment, and the particle morphology is further controlled and modified by equipment mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com