One-component strong adhesive and its preparation method and application

An adhesive, one-component technology, used in adhesives, adhesive types, polyurea/polyurethane adhesives, etc. The effect of rigidity, initial viscosity improvement, and crystallinity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

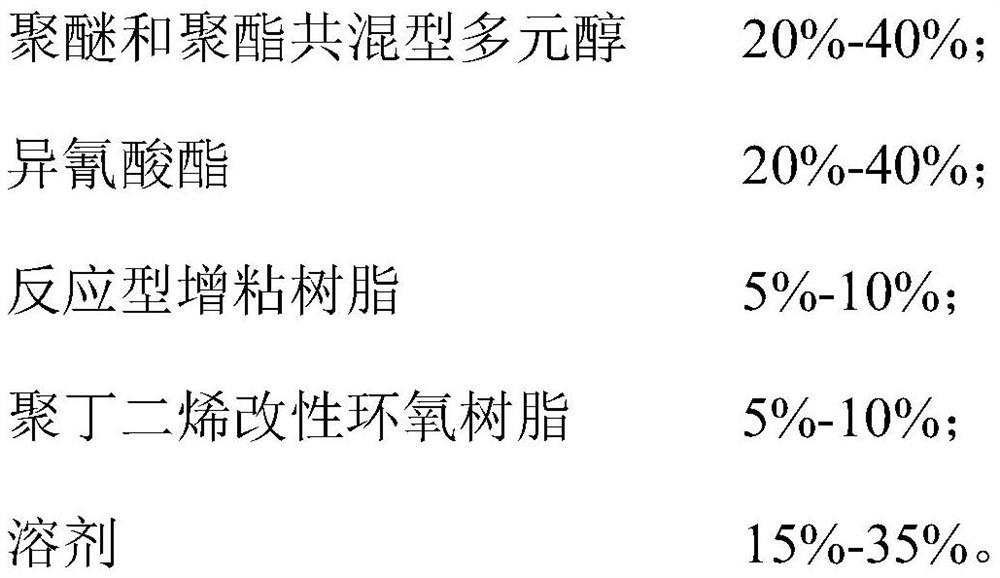

[0040] This embodiment provides a one-component strong adhesive prepared from the following raw materials in weight percentage:

[0041] 30% polyether and polyester blend polyol Kosin polyol-1000, 30% isocyanate Suprasec2020, 5% phenolic resin Kosin resin-2#, 10% polybutadiene modified epoxy resin, 15% butanone and 10% ethyl acetate.

[0042] The preparation method is:

[0043] Pour the isocyanate Suprasec 2020 into a stirred tank and heat it to 80°C, add 20% polyether and polyester blend polyol Kosin polyol-1000, control the reaction temperature between 70-90°C, react for 2 hours, add 10% Polybutadiene modified epoxy resin was reacted for 1 hour to obtain modified isocyanate prepolymer.

[0044] Add the remaining polyether and polyester blend polyol Kosinpolyol-1000 to the above-mentioned modified isocyanate prepolymer, seal and react for 2 hours, lower the temperature of the material to 50°C, add methyl ethyl ketone and ethyl acetate and stir evenly, seal and react for 0.5...

Embodiment 2

[0046] This embodiment provides a one-component strong adhesive prepared from the following raw materials in weight percentage:

[0047] 30% polyether and polyester blend polyol Kosin polyol-1000, 30% isocyanate Suprasec2020, 8% polybutadiene modified epoxy resin, 5% phenolic resin Kosin resin-2#, 5% The phenolic resin Kosinresin-3#, 12% methyl ethyl ketone and 10% ethyl acetate.

[0048] The preparation method is:

[0049] Pour the isocyanate Suprasec 2020 into a stirred tank and heat it to 80°C, add 20% polyether and polyester blend polyol Kosin polyol-1000, control the reaction temperature between 70-90°C, react for 2 hours, add 10% Polybutadiene modified epoxy resin was reacted for 1 hour to obtain modified isocyanate prepolymer.

[0050] Add the remaining polyether and polyester blended polyol Kosin polyol-1000 to the above isocyanate prepolymer, seal and react for 2 hours, lower the material temperature to 50°C, add methyl ethyl ketone and ethyl acetate and stir evenly...

Embodiment 3

[0052] This embodiment provides a one-component strong adhesive prepared from the following raw materials in weight percentage:

[0053]35% polyether and polyester blend polyol, 30% isocyanate Suprasec 2020, 5% phenolic resin Kosin resin-2#, 5% phenolic resin Kosin resin-3#, 5% polybutadiene Modified epoxy resin, 10% methyl ethyl ketone and 10% ethyl acetate.

[0054] The preparation method is:

[0055] Pour the isocyanate Suprasec 2020 into a stirred tank and heat it to 80°C, add 25% polyether and polyester blend polyol Kosin polyol-1000, control the reaction temperature between 70-90°C, react for 2 hours, add 5% Polybutadiene modified epoxy resin was reacted for 1 hour to obtain modified isocyanate prepolymer.

[0056] Add the remaining polyether and polyester blended polyol Kosin polyol-1000 to the above isocyanate prepolymer, seal and react for 2 hours, lower the material temperature to 50°C, add methyl ethyl ketone and ethyl acetate and stir evenly, seal and react for 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com