Vat cleaner for foaming

A cleaning agent and foaming technology, applied in the direction of detergent composition, detergent compounding agent, detergent composition solvent, etc., can solve the problems of waste, only cutting granulation, cleaning, etc., to improve storage time and promote reaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

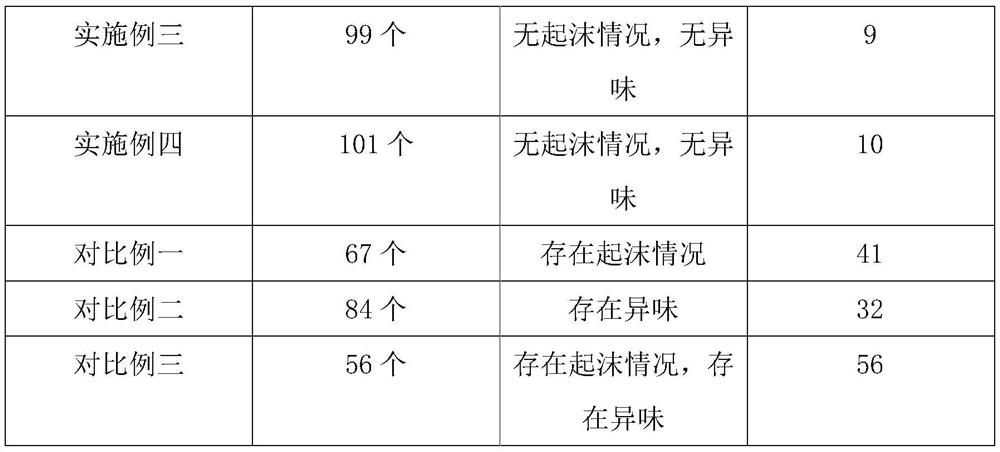

Examples

Embodiment 1

[0026] The vat cleaning agent for foaming specially proposed by the present invention includes 5% of defoamer, 3% of adhesive agent, 20% of second solvent and 72% of first solvent by mass percentage, and said defoamer includes oily 100% defoamer, the first solvent includes 69% ethyl acetate, 2% carbonate, 1% sodium methyl cocoyl taurate, 1% simethicone, 12 p-coumaric acid by mass percentage % and 15% water, the second solvent includes 5% xylene, 65% methanol and 3% water by mass percentage.

[0027] Wherein, the adhesion agent includes 100% soybean peptide by mass percentage, and the defoamer is GPE oily defoamer.

[0028] In the embodiment, also include a kind of preparation method of the vat cleaning agent specially for foaming, comprising the following steps:

[0029] S1: Add ethyl acetate, carbonate, sodium methyl cocoyl taurate, and dimethyl silicon into the mixing kettle according to the above mass percentage at room temperature, heat half of the water to 55°C and add i...

Embodiment 2

[0034] The vat cleaning agent for foaming specially proposed by the present invention comprises 7% of defoamer, 4% of adhesion agent, 22% of second solvent and 67% of first solvent by mass percentage, and said defoamer comprises oily 100% defoamer, the first solvent includes 62% ethyl acetate, 3% carbonate, 2% methyl cocoyl sodium taurate, 2% simethicone, 14 p-coumaric acid by mass percentage % and water 17%, the second solvent includes 5% xylene, 65% methanol and 3% water by mass percentage.

[0035] Wherein, the adhesion agent includes 100% soybean peptide by mass percentage, and the defoamer is GPE oily defoamer.

[0036] In the embodiment, also include a kind of preparation method of the vat cleaning agent specially for foaming, comprising the following steps:

[0037] S1: Add ethyl acetate, carbonate, sodium methyl cocoyl taurate, and dimethyl silicon into the mixing kettle according to the above mass percentage at room temperature, and add half of the water to the mixin...

Embodiment 3

[0042]The vat cleaning agent for foaming specially proposed by the present invention comprises 9% of defoaming agent, 4% of adhesion agent, 24% of second solvent and 63% of first solvent by mass percentage, and said defoaming agent comprises oily 100% defoamer, the first solvent includes 56% ethyl acetate, 4% carbonate, 4% sodium methyl cocoyl taurate, 2% simethicone, 16 p-coumaric acid by mass percentage % and water 18%, the second solvent includes 5% xylene, 65% methanol and 3% water by mass percentage.

[0043] Wherein, the adhesion agent includes 100% soybean peptide by mass percentage, and the defoamer is GPE oily defoamer.

[0044] In the embodiment, also include a kind of preparation method of the vat cleaning agent specially for foaming, comprising the following steps:

[0045] S1: Add ethyl acetate, carbonate, sodium methyl cocoyl taurate, and dimethyl silicon into the mixing kettle according to the above mass percentage at room temperature, heat half of the water to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com