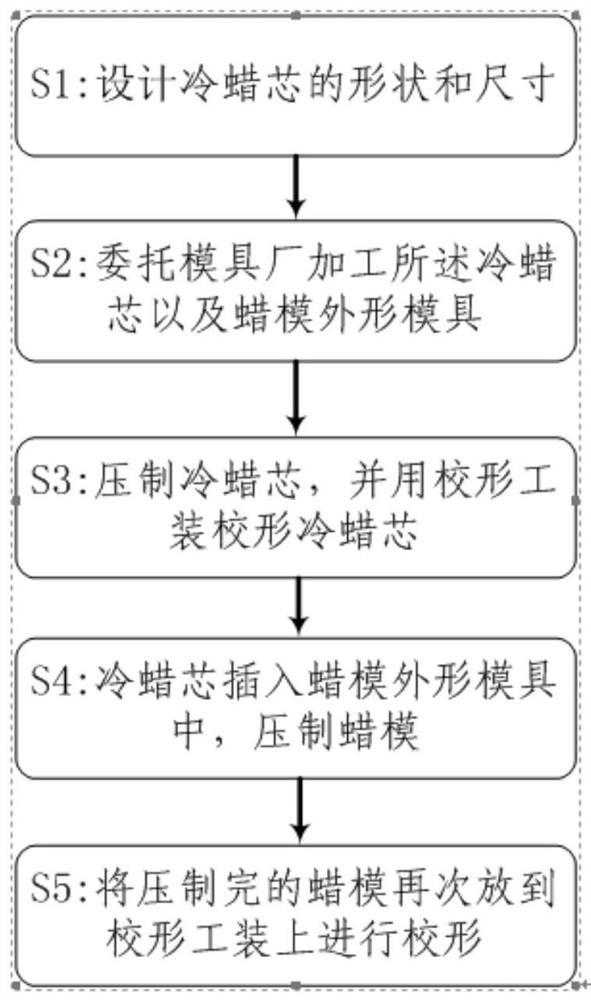

Anti-deformation process of wax mold for high-temperature alloy turbine rotor

A turbine rotor and superalloy technology, which is applied in metal processing equipment, manufacturing tools, casting and molding equipment, etc., can solve the problems of cold wax core design and calibration tooling that are difficult to meet the requirements of use, out of tolerance castings, and affecting the pass rate. , to achieve the effect of not easy to dislocate, speed up cooling, and solve serious deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

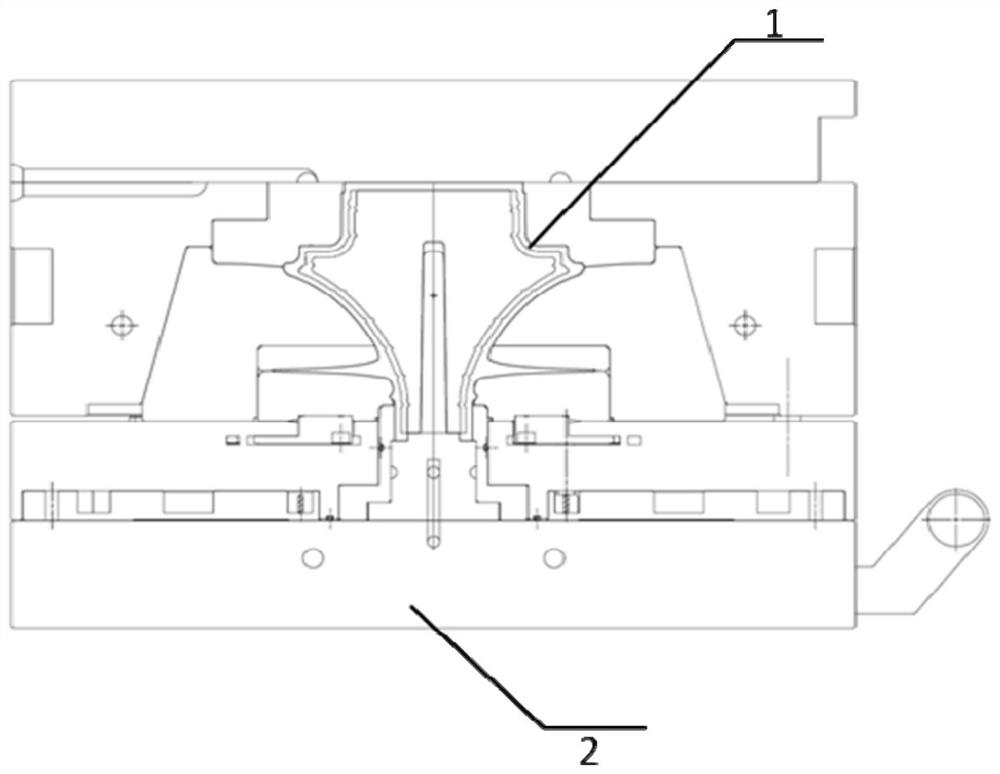

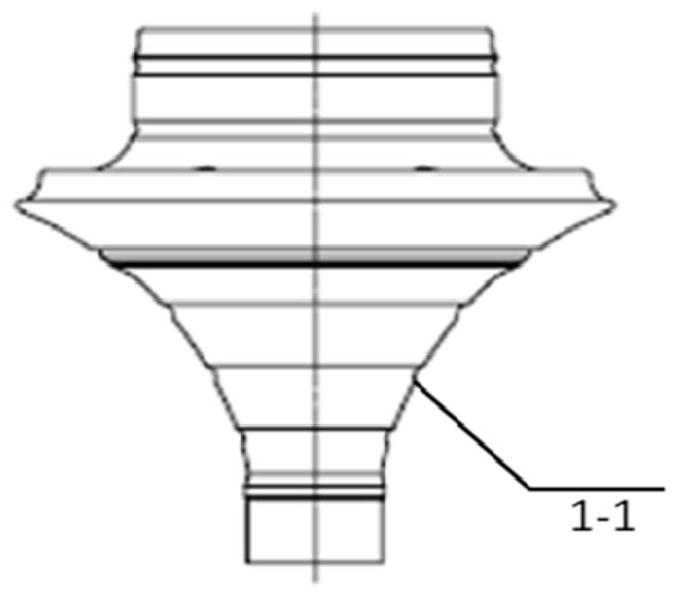

[0044] Embodiment: Experiments were carried out according to the method of the present invention, and the research experiment on the anti-deformation of the wax mold was carried out on the high-temperature part of the ground gas engine-turbine rotor prepared from the MAR-M247 alloy. The cold wax core that conforms to the shape of the wax mold product is pressed. The cold wax core is provided with grooves and through holes. The groove is arc-shaped, with a depth of 0.5-4.5mm and a width of 0.5-4.5mm; the through holes are evenly distributed And it is set on the height direction of the thick area of the cold wax core, the diameter of the through hole is 1-6mm; there is a gap of 2-5mm between the cold wax core and the inner cavity wall of the wax pattern mold; for the convenience of cold wax Core shape correction, the center of the cold wax core is conical hollow, the diameter of the cone is 1-10mm, and the height is 10-150mm; The balance table is composed of the fixed shaft an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com