Environment-friendly vegetation concrete

An environmentally friendly technology of vegetation concrete, applied in the field of ecological restoration engineering, can solve the problems of poor slope protection effect, low survival rate, and poor growth condition of vegetation concrete, and achieve the goal of realizing repeated use, improving economic benefits, and improving growth conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

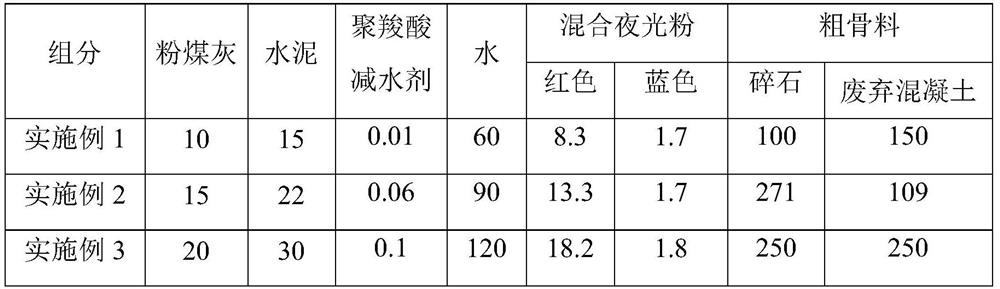

Embodiment 1

[0045] An environment-friendly vegetation concrete is prepared through the following steps:

[0046]S1. Stir 10 parts of fly ash, 15 parts of cement, 0.01 part of polycarboxylate superplasticizer and 60 parts of water to form cemented slurry A;

[0047] S2. Add 10 parts of mixed luminous powder A formed by red luminous powder and blue luminous powder with a mass ratio of 5:1 into the cemented slurry A prepared in S1, and stir well until the mixed luminous powder A is fully mixed in the cement In slurry A, cemented slurry B is formed;

[0048] S3. Add 250 parts of mixed coarse aggregate (including 150 parts of waste concrete and 100 parts of crushed stone, the weight ratio of waste concrete to crushed stone is 1.5:1) into the cementitious slurry B prepared in S2 to make cementation The slurry B is evenly wrapped on the surface of the coarse aggregate A, and finally the uniformly stirred concrete is poured into the mold, vibrated and smoothed, and an environment-friendly vegeta...

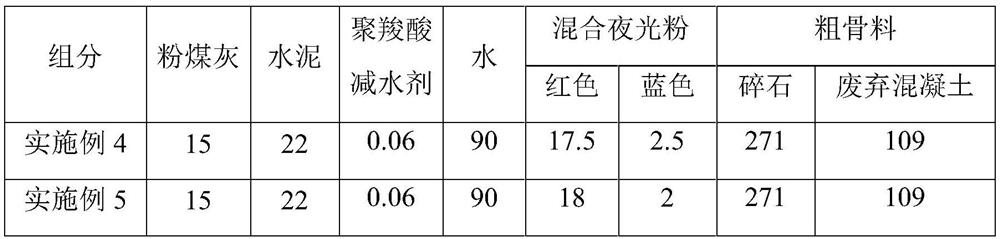

Embodiment 2

[0050] An environment-friendly vegetation concrete is prepared through the following steps:

[0051] S1. Stir 15 parts of fly ash, 22 parts of cement, 0.06 parts of polycarboxylate high-performance water reducer and 90 parts of water to form cemented slurry A;

[0052] S2. Add 15 parts of mixed luminous powder A formed by red luminous powder and blue luminous powder with a mass ratio of 8:1 to the cemented slurry A prepared in S1, and stir well until the mixed luminous powder A is fully mixed in the cement In slurry A, cemented slurry B is formed;

[0053] S3. Add 380 parts of mixed coarse aggregate (including 109 parts of waste concrete and 271 parts of crushed stone, the weight ratio of waste concrete to crushed stone is 1:2.5) into the cementitious slurry B prepared in S2 to make cementation The slurry B is evenly wrapped on the surface of the coarse aggregate A, and finally the uniformly stirred concrete is poured into the mold, vibrated and smoothed, and an environment-f...

Embodiment 3

[0055] An environment-friendly vegetation concrete is prepared through the following steps:

[0056] S1. Stir 20 parts of fly ash, 30 parts of cement, 0.1 part of polycarboxylate superplasticizer and 120 parts of water to form cemented slurry A;

[0057] S2. Add 20 parts of mixed luminous powder A formed by red luminous powder and blue luminous powder in a mass ratio of 10:1 to the cemented slurry A prepared in S1, and stir well until the mixed luminous powder A is fully mixed in the cement In slurry A, cemented slurry B is formed;

[0058] S3. Add 500 parts of mixed coarse aggregate (including 250 parts of waste concrete and 250 parts of crushed stone, the weight ratio of waste concrete to crushed stone is 1:1) into the cementitious slurry B prepared in S2 to make the cement The slurry B is evenly wrapped on the surface of the coarse aggregate A, and finally the uniformly stirred concrete is poured into the mold, vibrated and smoothed, and an environment-friendly vegetation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com