Heat-resistant high-strength halogen-free flame-retardant polyester film and preparation method thereof

A flame-retardant polyester, high-strength technology, applied in the field of polyester film, can solve the problems of pollution, large equipment investment, decomposition, etc., and achieve the effect of strong operability and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

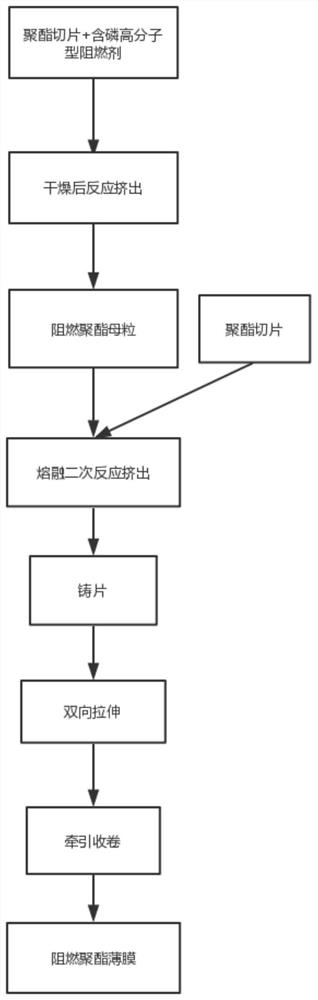

Method used

Image

Examples

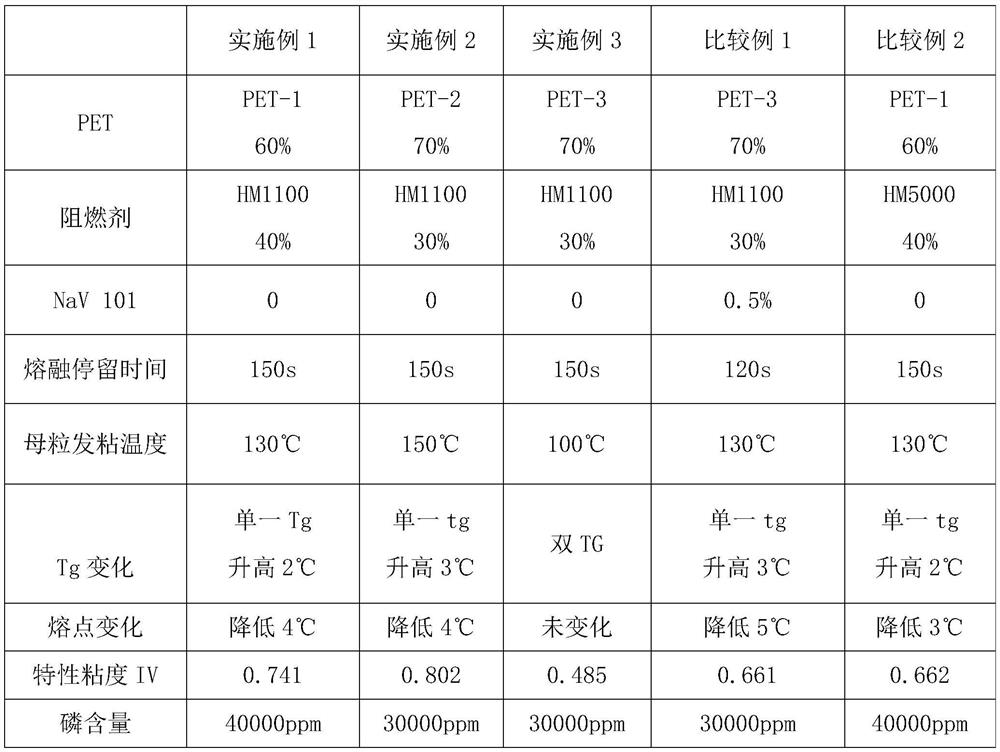

Embodiment 1

[0043] The final content of phosphorus-containing polymer flame retardant is 15%, and the final content of polyester chips (PET) is 85%.

[0044] Dry the upper polyester chip (PET) and phosphorus-containing polymer flame retardant in dew point drying equipment. The drying temperature of polyester chip (PET) is 160 ° C, and the drying time is 3 to 5 hours. The drying temperature of the flame retardant is 85°C, and the drying time is 6-8 hours. At the end of the final drying, the measured raw material moisture should be less than 200ppm, and then transported into the twin-screw reaction extruder with vacuum. The temperature of the extruder Set it at 200-285°C, control the reaction extrusion time through the extrusion volume and extrusion speed, and finally cool and cut into pellets to obtain flame-retardant masterbatches.

[0045] Then add the flame retardant masterbatch and polyester chips (PET) into the extruder respectively, the two polyesters undergo a secondary transesterif...

Embodiment 2

[0048] Among them, the final content of phosphorus-containing polymer flame retardant is 18%, and the final content of polyester chips (PET) is 82%.

[0049] Dry the upper polyester chip (PET) and phosphorus-containing polymer flame retardant in dew point drying equipment. The drying temperature of polyester chip (PET) is 160 ° C, and the drying time is 3 to 5 hours. The drying temperature of the flame retardant is 85°C, and the drying time is 6-8 hours. At the end of the final drying, the measured raw material moisture should be less than 200ppm, and then transported into the twin-screw reaction extruder with vacuum. The temperature of the extruder Set it at 200-285°C, control the reaction extrusion time through the extrusion volume and extrusion speed, and finally cool and cut into pellets to obtain flame-retardant masterbatches.

[0050]Then add the flame retardant masterbatch and polyester chips (PET) into the extruder respectively, the two polyesters undergo a secondary t...

Embodiment 3

[0053] The final content of phosphorus-containing polymer flame retardant is 20%, and the final content of polyester chips (PET) is 80%.

[0054] Dry the upper polyester chip (PET) and phosphorus-containing polymer flame retardant in dew point drying equipment. The drying temperature of polyester chip (PET) is 160 ° C, and the drying time is 3 to 5 hours. The drying temperature of the flame retardant is 85°C, and the drying time is 6-8 hours. At the end of the final drying, the measured raw material moisture should be less than 200ppm, and then transported into the twin-screw reaction extruder with vacuum. The temperature of the extruder Set it at 200-285°C, control the reaction extrusion time through the extrusion volume and extrusion speed, and finally cool and cut into pellets to obtain flame-retardant masterbatches.

[0055] Then add the flame retardant masterbatch and polyester chips (PET) into the extruder respectively, the two polyesters undergo a secondary transesterif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com