Air path opening and closing combined drying device

A drying device and gas path technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of heat pump system structure complexity, heat pump system stability, reliability decline, etc., to achieve system reliability improvement, The effect of simplification of the structure of the fluorine circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

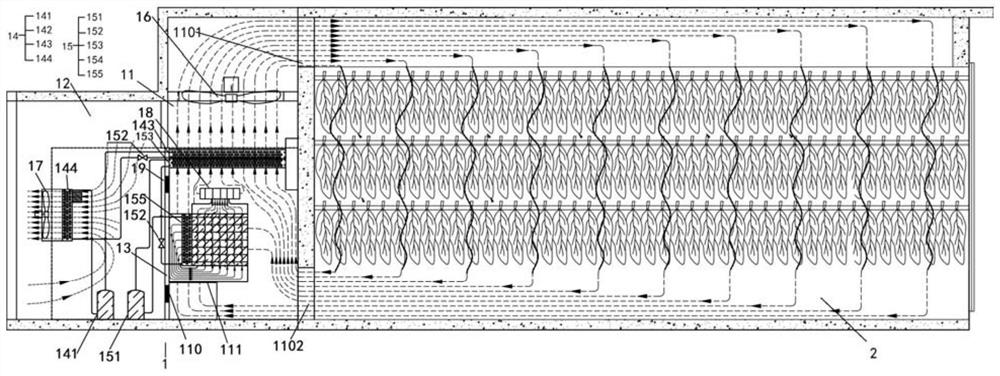

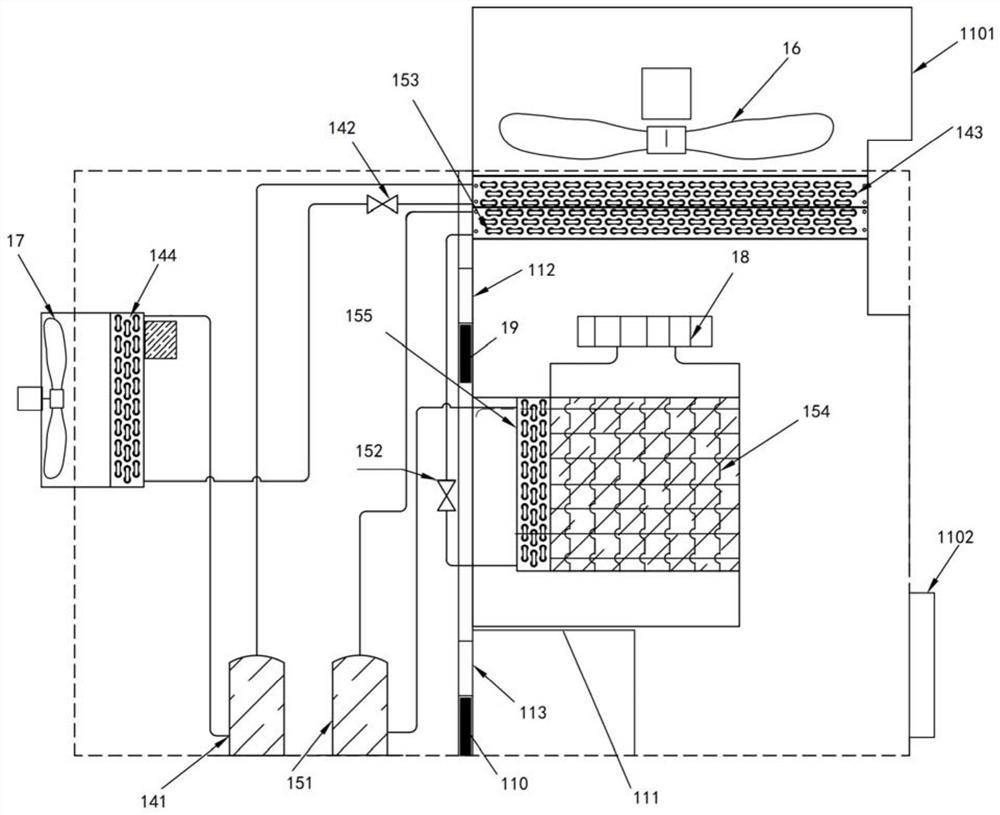

[0061] Please refer to Figure 2 to Figure 9 The drying device provided in this embodiment takes a heat pump unit as an example. This heat pump unit is composed of at least one heat pump unit 15 with internal dehumidification and internal heating and at least one heat pump unit 14 with external heat absorption and internal heating. The heat pump unit 15 for internal dehumidification and internal heating is used for Internal dehumidification and internal heating, external heat absorption and internal heating The heat pump unit 14 is used for external heat absorption and internal heating.

[0062] In this embodiment, the wall of the inner cavity 11 is provided with an air inlet 1102 and an air outlet 1101 for communicating with the barn 2, the air inlet 1102 is located below the inner cavity 11, and the air outlet 1101 is located at the bottom of the inner cavity 11. above. A first fan 16 is provided at the air outlet 1101 .

[0063] The heat pump unit 14 for external heat abs...

Embodiment 2

[0085] The basic principle of this embodiment is the same as that of Embodiment 1, the difference is that in Embodiment 1, the fresh air outlet 112, the moisture discharge outlet 113, the fresh air damper 19, the moisture discharge damper 110 and the driving device are all arranged on the partition 13, while this embodiment Embodiment The fresh air port 112, the moisture discharge port 113, the fresh air damper 19, the humidity discharge damper 110 and the driving device are all arranged on the inner cavity side wall 1103, please refer to Figure 20 In addition to all the advantages of Embodiment 1, this embodiment also has the advantages of being convenient for maintenance and not competing with the outer chamber 12 for fresh air flow when making up fresh air.

Embodiment 3

[0087] Please refer to Figure 10 to Figure 19 In this embodiment, on the basis of Embodiment 1 and Embodiment 2, a dehumidification guide plate 111 is added, that is, in the inner cavity 11, above the dehumidification port 113 and below the inner dehumidification module (that is, dehumidification Between the port 113 and the inner dehumidification module) there is a moisture-discharging guide plate 111 , and the moisture-discharging guide plate 111 is rotatably disposed on the partition 13 or the inner cavity side wall 1103 . When the moisture discharge damper 110 is opened, the moisture discharge guide plate 111 is unfolded; when the moisture discharge damper 110 is closed, the moisture discharge guide plate 111 is retracted.

[0088] Preferably, when the new air port 112, the moisture discharge port 113, the fresh air damper 19, the moisture discharge damper 110 and the driving device are all arranged on the partition 13, the moisture discharge guide plate 111 is also arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com