Method for extracting bromine-magnesium compound from Grignard reaction wastewater and mother liquor

A technology of Grignard reaction and compound, which is applied in the field of Grignard reaction wastewater and mother liquor treatment, can solve the problems such as the reduction of reaction yield, and achieve the effects of high purity, environmental protection and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

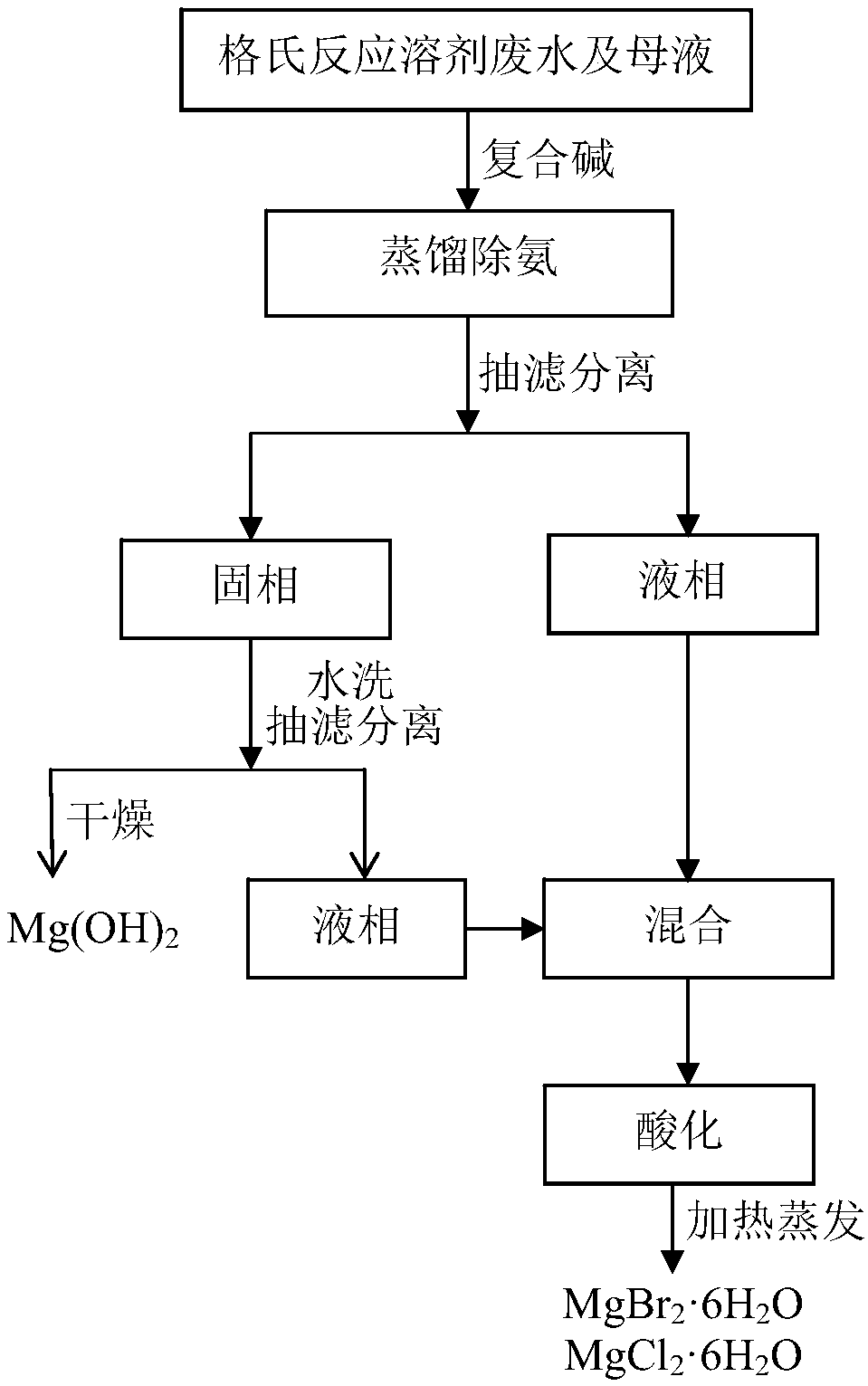

[0025] Present embodiment provides a kind of method that extracts bromine-magnesium compound from Grignard reaction waste water and mother liquor, and its steps are as follows: see image 3 .

[0026] (1) Add compound alkali (mass fraction: NaOH is 10wt%, MgO is 90wt%) to distill and remove ammonia in Grignard reaction waste water and mother liquor, the pH of compound alkali is 11.0, heating temperature is to 106 ℃, heating time is 3h , During the heating process, ammonia gas is continuously precipitated, and a certain volume of water is used to absorb ammonia gas, and the change of pH value and concentration is dynamically detected. The final pH value was stable at 12.0, indicating that the ammonia gas had completely evolved.

[0027] (2) Suction filtration is carried out to the waste water after the deamination, after solid-liquid separation for the first time, after adopting 10 times of water to wash the solid phase filter cake after separation, carry out solid-liquid sepa...

Embodiment 2

[0030] Present embodiment provides a kind of method that extracts bromine-magnesium compound from Grignard reaction waste water and mother liquor, and its steps are as follows: see image 3 .

[0031] (1) Add composite alkali (mass fraction: NaOH is 20wt%, MgO is 80wt%) in Grignard reaction waste water and mother liquor and carry out distillation and remove ammonia, the pH of composite alkali is 11.5, and heating temperature is to 103 ℃, and heating time is 1.5 h, during the heating process, ammonia gas is continuously precipitated, and a certain volume of water is used to absorb ammonia gas, and the change of pH value and concentration is dynamically detected. The final pH value was stable at 11.8, indicating that the ammonia gas had been completely released.

[0032] (2) Suction filtration is carried out to the waste water after the deamination, after solid-liquid separation for the first time, after adopting 12 times of water to wash the solid phase filter cake after separ...

Embodiment 3

[0035] Present embodiment provides a kind of method that extracts bromine-magnesium compound from Grignard reaction waste water and mother liquor, and its steps are as follows: see image 3 .

[0036] (1) Add compound alkali (mass fraction: NaOH is 35wt%, MgO is 65wt%) to distill and remove ammonia in Grignard reaction waste water and mother liquor, the pH of compound alkali is 12.3, heating temperature is to 105 ℃, heating time is 2h , During the heating process, ammonia gas is continuously precipitated, and a certain volume of water is used to absorb ammonia gas, and the change of pH value and concentration is dynamically detected. The final pH value was stable at 12.1, indicating that the ammonia gas had completely evolved.

[0037] (2) Suction filtration is carried out to the waste water after the deamination, after solid-liquid separation for the first time, after adopting 10 times of water to wash the solid phase filter cake after separation, carry out solid-liquid sepa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com