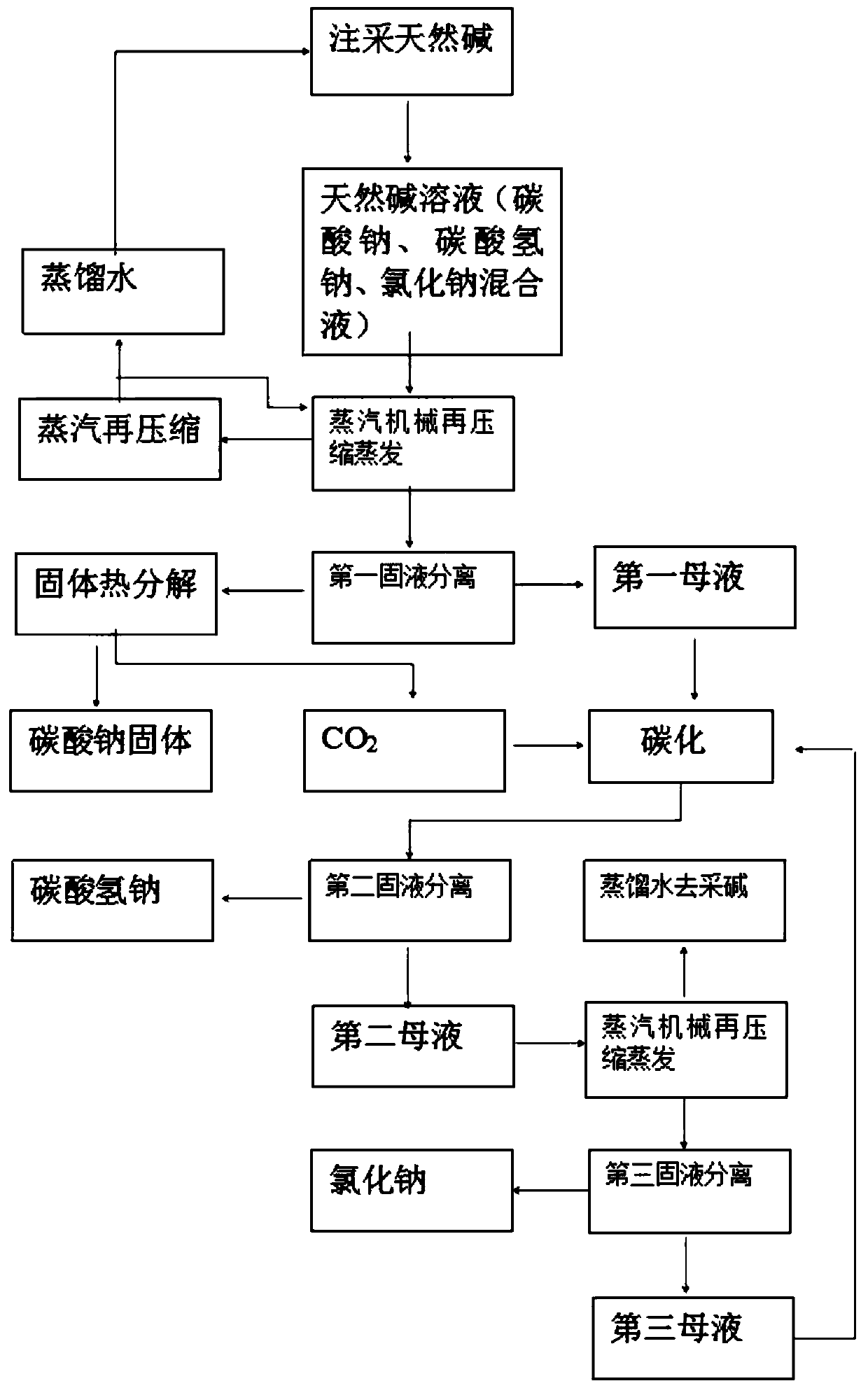

Method and system for producing sodium carbonate, sodium bicarbonate and sodium chloride by evaporating natural alkali liquid

A technology of sodium bicarbonate and sodium carbonate, applied in the directions of alkali metal chlorides, alkali metal carbonates, chemical instruments and methods, etc., can solve the problem of low recovery rate of condensed water, low utilization of condensed water, impact on production costs of enterprises, and complex components of trona. and other problems, to achieve relatively high profits, significant economic and environmental benefits, and reliable methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

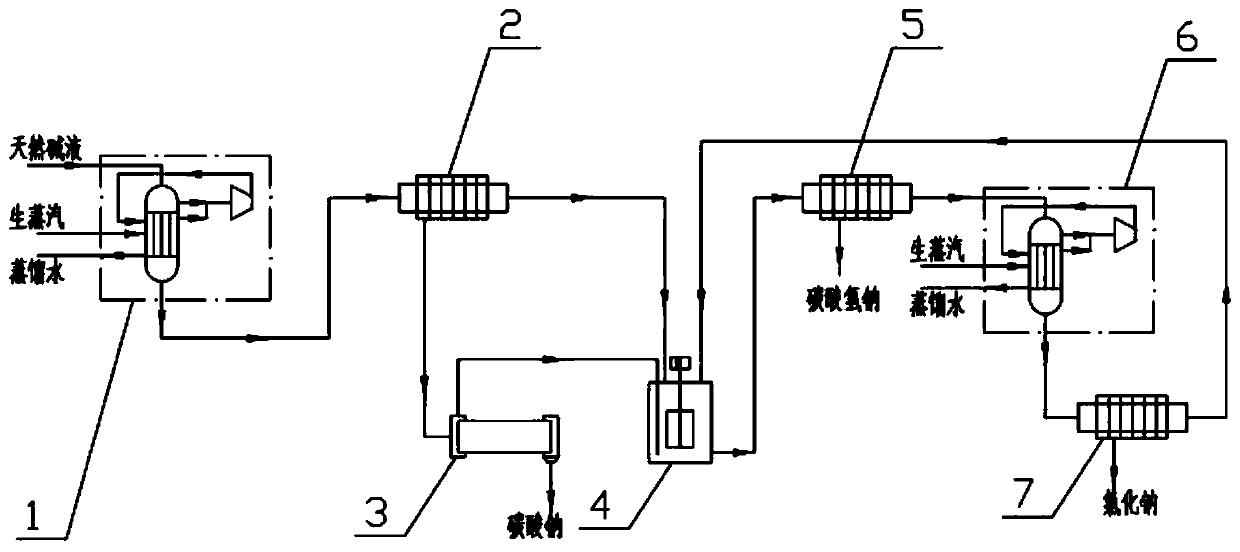

[0065] 10,000L of mined natural lye (contains 100g / L sodium carbonate, 95g / L sodium bicarbonate, 10g / L sodium chloride, and 925g / L water) is filtered and removed, and then sent to the steam machine for further processing. Compression evaporation device 1, (the device is equipped with a centrifugal steam compressor, which can realize the low-temperature evaporation of natural lye and at the same time evaporate the saturated water vapor to be used for the evaporation of natural lye after compression and heating), evaporated at 96 ° C Saturated water vapor is recompressed and heated to 106°C for trona evaporation, and at the same time, the first solid-liquid mixture and condensed distilled water 6500L are obtained. The distilled water is used for trona injection and production, and non-condensable water vapor is discharged;

[0066] After the first solid-liquid mixture is cooled, enter the first solid-liquid separation device 2 for solid-liquid separation to obtain mixed alkali of...

Embodiment 2

[0073] 10,000L of mined natural lye (tested to contain 120g / L sodium carbonate, 85g / L sodium bicarbonate, 15g / L sodium chloride, and 920g / L water) is filtered and removed, and then transported to the steam machinery Compression evaporation device 1, (the device is equipped with a centrifugal steam compressor, which can realize the low-temperature evaporation of natural lye and at the same time evaporate the saturated water vapor to be used for the evaporation of natural lye after compression and heating), evaporated at 94 ° C Saturated water vapor is recompressed and heated to 105°C for trona evaporation, and the first solid-liquid mixture and condensed distilled water 6100L are obtained at the same time. The distilled water is used for trona injection and recovery, and non-condensable water vapor is discharged;

[0074] After the first solid-liquid mixture is cooled, it is passed into the first solid-liquid separation device 2 for solid-liquid separation to obtain mixed alkali...

Embodiment 3

[0081] 10,000L of mined natural lye (tested to contain sodium carbonate 80g / L, sodium bicarbonate 115g / L, sodium chloride 20g / L, and other components are water 950g / L) is filtered and removed, and then transported to the steam machine for further processing. Compression evaporation device 1, (the device is equipped with a Roots-type steam compressor, which can realize the low-temperature evaporation of natural lye and at the same time evaporate the saturated water vapor to be used for the evaporation of natural lye after compression and heating), evaporate at 96°C to obtain The saturated water vapor was recompressed and heated to 103°C for trona evaporation, and at the same time, the first solid-liquid mixture and 6230kg of distilled water were obtained, and the distilled water was used for injection and production of trona;

[0082] After the first solid-liquid mixture is cooled, it is passed into the first solid-liquid separation device 2 for solid-liquid separation to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com