Tannic acid-polypyrrole-graphene oxide composite gel and preparation method and application thereof

A graphene composite and tannic acid technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of improving electrochemical performance, improving agglomeration, and strengthening interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of tannic acid-polypyrrole-graphene oxide composite gel, comprising the steps of:

[0031] 1) Take 4 mg of tannic acid to prepare an aqueous solution of tannic acid with a concentration of 0.3 wt%, then add 33.5 mg of pyrrole and stir for 10 min at 4° C., add 6 mg of graphene oxide and continue stirring for 10 min, and mix well to obtain tannic acid- Pyrrole-graphene oxide blend;

[0032] 2) Dissolve 0.1g of ferric chloride in 5ml of deionized water and add it to the tannic acid-pyrrole-graphene oxide blend obtained in step 1), and then stand at 10°C for 24h to obtain tannic acid- Polypyrrole-graphene oxide composite gel.

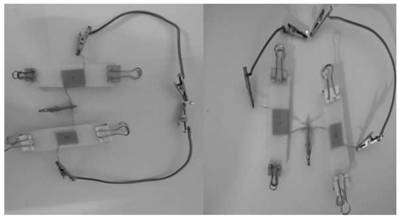

[0033] The tannic acid-polypyrrole-graphene oxide composite gel obtained in this embodiment is as follows: figure 1 .

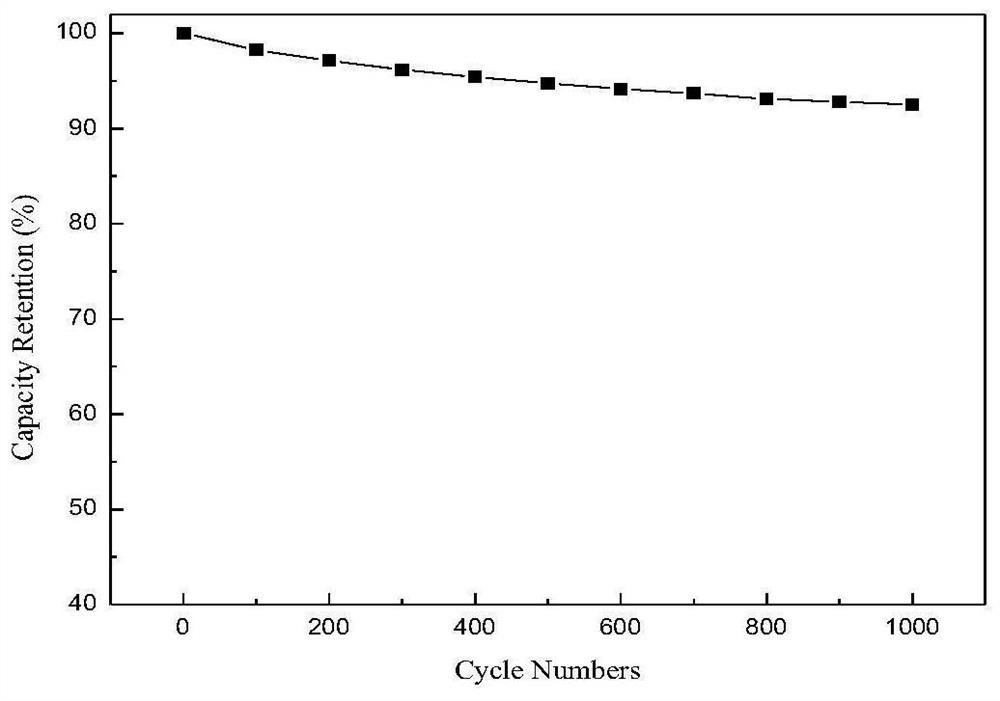

[0034] The tannic acid-polypyrrole-graphene oxide composite gel prepared in this example was tested for electrochemical performance. The test instrument was Chenhua Electrochemical Workstation CHI900C, and th...

Embodiment 2

[0037] A preparation method of tannic acid-polypyrrole-graphene oxide composite gel, comprising the steps of:

[0038] 1) Take 4 mg of tannic acid to prepare an aqueous solution of tannic acid with a concentration of 0.3 wt%, then add 33.5 mg of pyrrole and stir for 30 min at 0° C., add 2 mg of graphene oxide and continue stirring for 30 min, and mix well to obtain tannic acid- Pyrrole-graphene oxide blend;

[0039] 2) Dissolve 0.1g of ferric chloride in 5ml of deionized water and add it to the tannic acid-pyrrole-graphene oxide blend obtained in step 1), and then stand at 15°C for 26h to obtain tannic acid- Polypyrrole-graphene oxide composite gel.

[0040] The tannic acid-polypyrrole-graphene oxide composite gel prepared in this example was tested for electrochemical performance. The test instrument was Chenhua Electrochemical Workstation CHI900C, and the test was carried out in sodium sulfate electrolyte. According to the capacitance calculation formula, in When the curre...

Embodiment 3

[0042] A preparation method of tannic acid-polypyrrole-graphene oxide composite gel, comprising the steps of:

[0043] 1) Take 4 mg of tannic acid to prepare an aqueous solution of tannic acid with a concentration of 0.3 wt%, then add 33.5 mg of pyrrole and stir for 20 min at 3° C., add 4 mg of graphene oxide and continue stirring for 20 min, and mix well to obtain tannic acid- Pyrrole-graphene oxide blend;

[0044] 2) Dissolve 0.1g of ferric chloride in 5ml of deionized water and add it to the tannic acid-pyrrole-graphene oxide blend obtained in step 1), and then stand at 10°C for 28h to obtain tannic acid- Polypyrrole-graphene oxide composite gel.

[0045] The tannic acid-polypyrrole-graphene oxide composite gel prepared in this example was tested for electrochemical performance. The test instrument was Chenhua Electrochemical Workstation CHI900C, and the test was carried out in sodium sulfate electrolyte. According to the capacitance calculation formula, in When the curre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com