Multi-electrode electroslag remelting device and electroslag remelting process for high-nitrogen austenitic stainless steel

A high-nitrogen austenite and electroslag remelting technology, applied in the field of electroslag remelting, can solve the problems of expensive electroslag remelting equipment and complicated operation process, achieve stable alloying, improve yield and power consumption low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention. Unless otherwise specified, the examples are all in accordance with conventional experimental conditions. In addition, for those skilled in the art, on the premise of not departing from the spirit and scope of the present invention, various modifications or improvements to the material components and dosage in these embodiments all belong to the protection scope of the present invention.

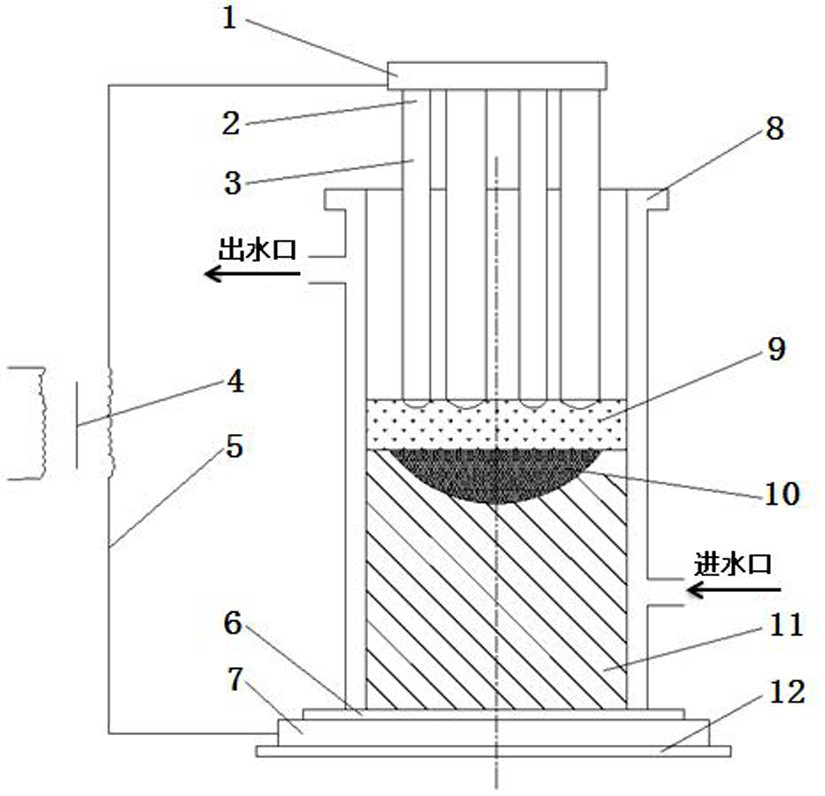

[0018] Such as figure 1 A multi-electrode electroslag remelting device for high-nitrogen austenitic stainless steel is shown, which includes a lifting electrode chuck 1 and an electroslag remelting furnace, wherein: the lifting electrode chuck 1 is arranged in the electroslag remelting furnace Above the furnace mouth, the dummy electrode 2 is installed under the lifting electrode chuck 1, and the consumable electrode 3 is installed under the dummy ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com