Medical wastewater multi-stage treatment device

A treatment device and waste water technology, which is applied in the field of medical equipment, can solve problems such as troubles and achieve good treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

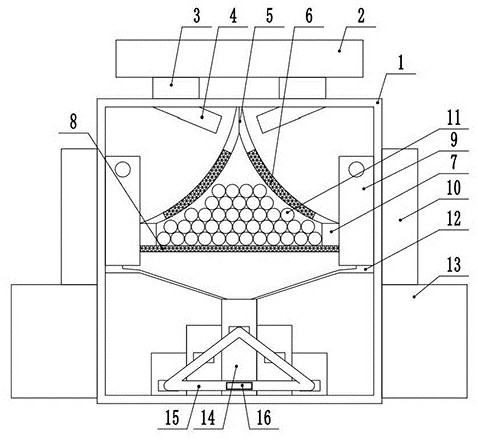

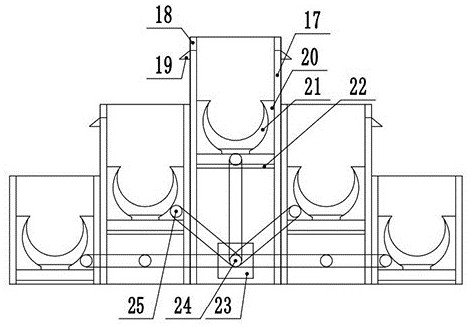

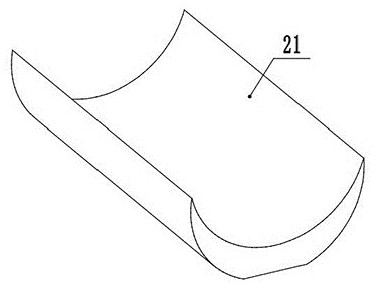

[0026] see Figure 1-8 , a multi-stage treatment device for medical wastewater, comprising a treatment box 1, a feed hopper 2 is arranged above the treatment box 1, two branch branch pipes 3 are fixedly connected between the bottom end of the feed hopper 2 and the treatment box 1, and the branch branch pipes The bottom end of 3 is fixedly connected to the discharge inclined pipe 4, and the discharge inclined pipe 4 is located in the processing box 1, and the top in the processing box 1 is fixedly connected to two arc-shaped separation plates 5. The tops of the two arc-shaped separation plates 5 are fixedly connected, arc-shaped Separation plate 5 is embedded with separation filter screen 6, both sides in the treatment box 1 are fixedly connected to separation side box 9, and separation side box 9 is provided with a garbage discharge mechanism, and the bottom end of arc-shaped separation plate 5 is fixedly connected to end seat 7. The end seat 7 is fixedly connected to the sepa...

Embodiment 2

[0033] see Figure 1-8 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the top of the bottom block 8 is provided with a plurality of buffer balls 11, and each buffer ball 11 is provided with a plurality of flow holes 27, and the flow holes 27 runs through the buffer ball 11.

[0034]During the implementation of the present invention, sewage enters the treatment box 1 from the feed hopper 2, and the sewage mixed with garbage washes on the separation filter screen 6 on the arc-shaped separation plate 5, and the sewage passes through the separation filter screen 6, and the garbage is washed away. Flow down and wash into the separation side box 1, start the conveying motor to drive the transmission belt 28 to run, the separation screen 30 moves to discharge the garbage, the sewage passes through the separation filter 6 and is blocked and buffered by the buffer ball 11, and becomes a gentle water flow downward And through the col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com