Nitrification tail gas treatment method and system

A treatment method and technology of a treatment system are applied in the treatment field of nitrification tail gas, which can solve the problems of consuming large adsorbents or lye, wasting nitric acid raw materials, and high treatment costs, and achieves reduction of nitric acid consumption, treatment cost, and low treatment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

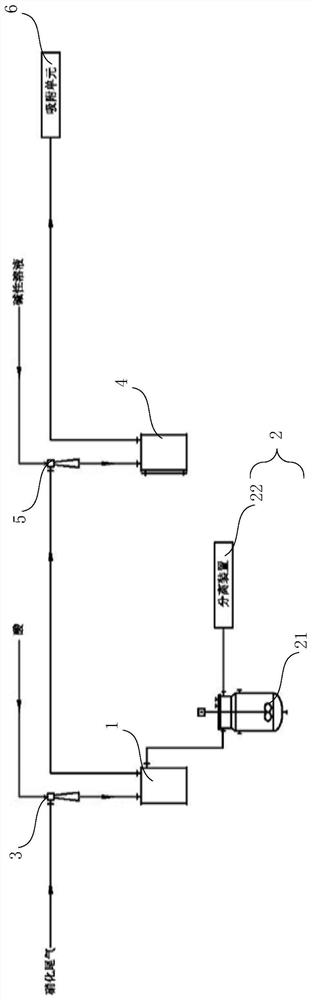

[0091] Nitrification tail gas, that is, NO in the tail gas produced by nitrification reaction x The content is 1000mg / m 3 , after the nitrification tail gas is mixed with the waste acid which is circulated in the nitrobenzene production system through the first mixer 3, it enters the acid absorption unit 1 to obtain the first tail gas and the first mixed liquid. The specific components of the waste acid are 68.0wt% sulfuric acid, 0.60wt% nitric acid and 31.4wt% water. Nitrification tail gas flow rate is 30m 3 / h, the waste acid flow rate is 9m 3 / h, the volume ratio of waste acid to nitrification tail gas is 9:30, the absorption temperature of waste acid is 20°C, and the flow rate of the first tail gas is 30m 3 / h. NO in nitrification tail gas x Absorbed by waste acid and converted into nitric acid, NO in the first tail gas x content reduced to 584mg / m 3 , The specific components of the first mixed solution are 67.99wt% sulfuric acid, 0.63wt% nitric acid, and 31.38wt% w...

Embodiment 2

[0095] Nitrification tail gas, that is, NO in the tail gas produced by nitrification reaction x The content is 1500mg / m 3 , after the nitrification tail gas is mixed with the waste acid which is circulated in the nitrobenzene production system through the first mixer 3, it enters the acid absorption unit 1 to obtain the first tail gas and the first mixed liquid. The specific components of the waste acid are 68.0wt% sulfuric acid, 0.5wt% nitric acid and 31.5wt% water. Nitrification tail gas flow rate is 34m 3 / h, the waste acid flow rate is 11m3 / h, the volume ratio of waste acid to nitrification tail gas is 11:34, the absorption temperature of waste acid is 30°C, and the flow rate of the first tail gas is 34m 3 / h. NO in nitrification tail gas x Absorbed by waste acid and converted into nitric acid, NO in the first tail gas x Content reduced to 900mg / m 3 , The specific components of the first mixed solution are 68wt% sulfuric acid, 0.54wt% nitric acid, and 31.46wt% water...

Embodiment 3

[0099] Nitrification tail gas, that is, NO in the tail gas produced by nitrification reaction x The content is 1300mg / m 3 , after the nitrification tail gas is mixed with the waste acid which is circulated in the nitrobenzene production system through the first mixer 3, it enters the acid absorption unit 1 to obtain the first tail gas and the first mixed liquid. The specific components of the waste acid are 67.95wt% sulfuric acid, 0.55wt% nitric acid and 31.5wt% water. Nitrification tail gas flow rate is 37m 3 / h, the waste acid flow rate is 12m 3 / h, the volume ratio of waste acid to nitrification tail gas is 12:37, the absorption temperature of waste acid is 38°C, and the flow rate of the first tail gas is 37m 3 / h. NO in nitrification tail gas x Absorbed by waste acid and converted into nitric acid, NO in the first tail gas x The content is reduced to 806mg / m 3 , The specific components of the first mixed solution are 67.94wt% sulfuric acid, 0.58wt% nitric acid, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com