Separation and purification method of high-purity ecdysone

An ecdysone, separation and purification technology, applied in the direction of organic chemistry, steroids, etc., can solve the problems of complex process, high cost, separation and purification, etc., to reduce environmental pollution, improve recovery rate, and improve the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

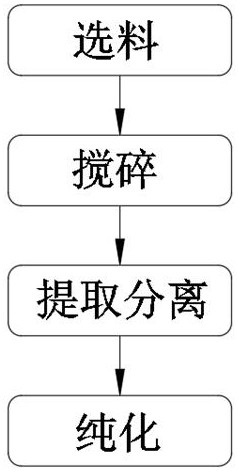

[0029] A method for separation and purification of high-purity ecdysone, its specific separation and purification comprises the following steps:

[0030] (1) Material selection: select 1-2 year old dew grass roots without rot, mildew, and no visible impurities, and take the dew grass roots for cleaning, drying, peeling, and drying to obtain the dew grass roots as raw material;

[0031] (2) Crushing: put the raw materials in step (1) into a pulverizer for pulverization, and then pass through a 60-mesh sieve to obtain dew grass powder;

[0032] (3) Extraction and separation: Put the dew grass powder into a high-performance liquid chromatograph for separation, and add an inducer to extract the ecdysone sample;

[0033] (4) Purification: The clarifier is used to adsorb the ecdysone sample to obtain high-purity ecdysone.

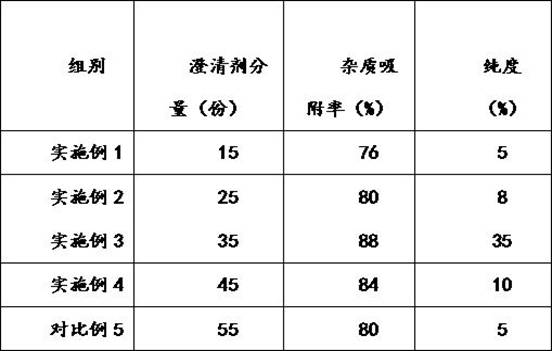

[0034] The dew grass root is 10 parts, the inducer is 50 parts, and the clarifying agent is 10 parts; the inducer is specifically CH3COOC2H5; the dew grass roo...

Embodiment 2

[0044] A method for separation and purification of high-purity ecdysone, its specific separation and purification comprises the following steps:

[0045] (1) Material selection: Select dew grass roots that are 1-2 years old and have no rot, mildew, and no visible impurities, and take the dew grass roots for cleaning, drying, peeling, and drying to obtain the dew grass roots as raw material;

[0046] (2) Crushing: put the raw materials in step (1) into a pulverizer for pulverization, and then pass through a 60-mesh sieve to obtain dew grass powder;

[0047](3) Extraction and separation: Put the dew grass powder into a high-performance liquid chromatograph for separation, and add an inducer to extract the ecdysone sample;

[0048] (4) Purification: The clarifier is used to adsorb the ecdysone sample to obtain high-purity ecdysone.

[0049] The dew grass root is 12 parts, the inducer is 55 parts, and the clarifying agent is 12 parts; the inducer is specifically CH3COOC2H5; the ...

Embodiment 3

[0059] A method for separation and purification of high-purity ecdysone, its specific separation and purification comprises the following steps:

[0060] (1) Material selection: Select dew grass roots that are 1-2 years old and have no rot, mildew, and no visible impurities, and take the dew grass roots for cleaning, drying, peeling, and drying to obtain the dew grass roots as raw material;

[0061] (2) Crushing: put the raw materials in step (1) into a pulverizer for pulverization, and then pass through a 60-mesh sieve to obtain dew grass powder;

[0062] (3) Extraction and separation: Put the dew grass powder into a high-performance liquid chromatograph for separation, and add an inducer to extract the ecdysone sample;

[0063] (4) Purification: The clarifier is used to adsorb the ecdysone sample to obtain high-purity ecdysone.

[0064] The dew grass root is 18 parts, the inducer is 58 parts, and the clarifying agent is 13 parts; the inducer is specifically CH3COOC2H5; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com