Explosion-proof material master batch with good low-temperature resistance and barrier property as well as preparation method and application thereof

A technology of explosion-proof material and barrier performance, which is applied in the field of explosion-proof material masterbatch and preparation, which can solve the problems that affect the explosion-suppression performance, the volume occupancy rate of explosion-suppression materials, the difficulty of improving the suppression performance, and the blockage of oil pipelines, so as to ensure the feasibility of preparation and implementation and production efficiency, excellent compatibility, and improved performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

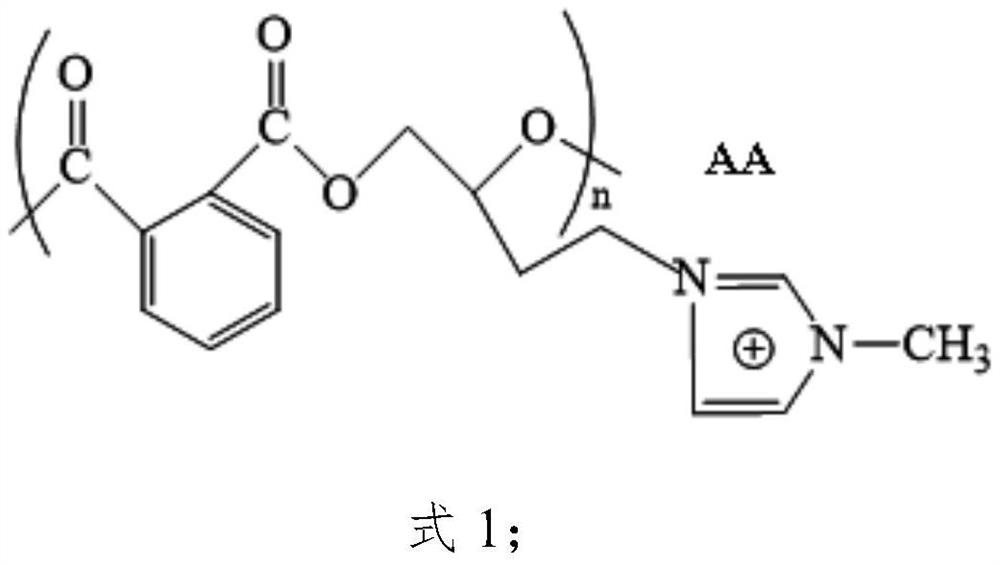

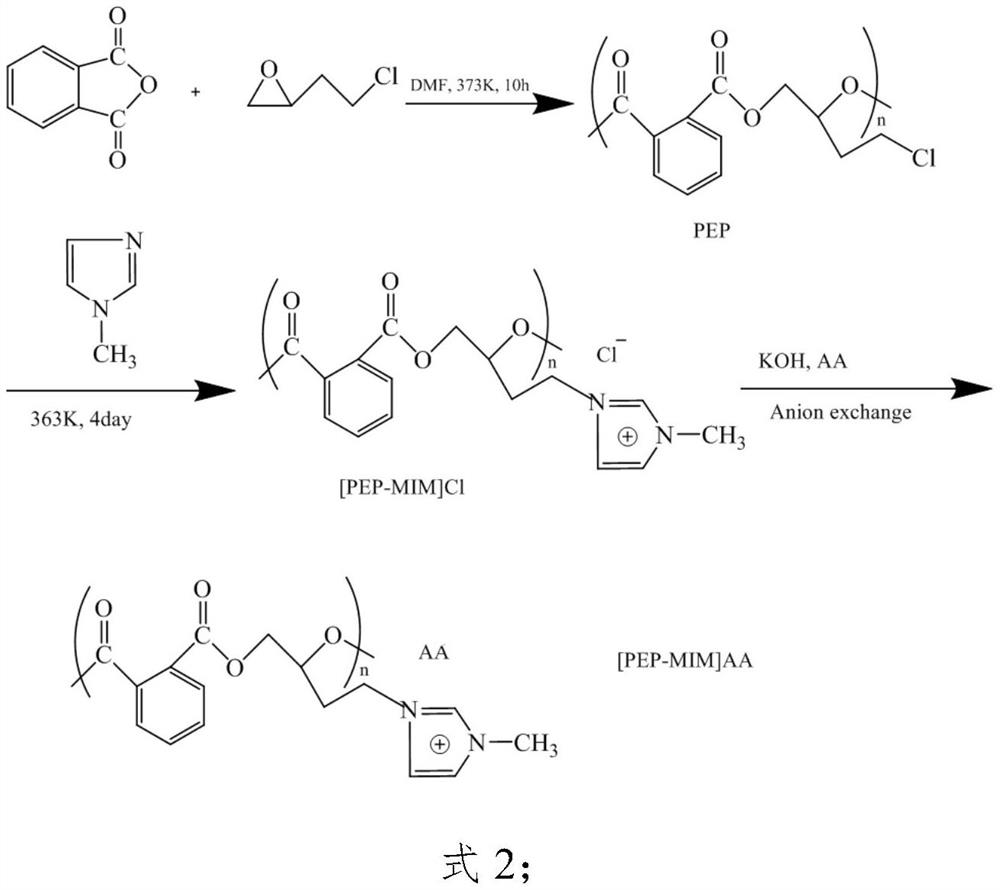

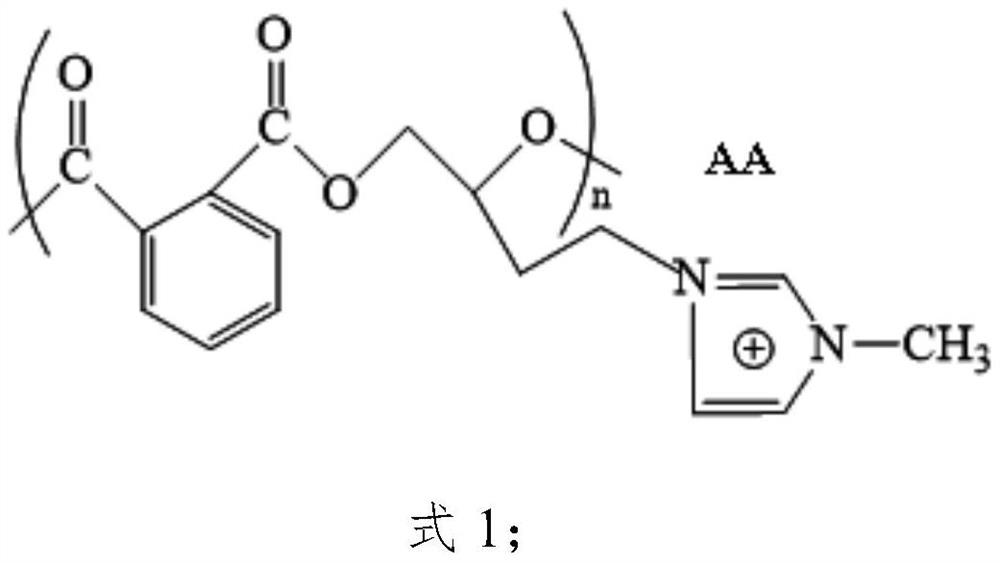

[0034] According to the method of the present invention, a masterbatch of explosion-proof material with good low-temperature resistance and barrier performance is prepared, and the operation steps are as follows:

[0035] (1) Preparation of polyolefin modifier

[0036]a. Weigh 14.8g of phthalic anhydride and dissolve it in 50ml of DMF, mix uniformly at 70°C in a nitrogen atmosphere, then slowly add 20ml of ethylene glycol and 8ml of epichlorohydrin equal to the molar weight of phthalic anhydride to the above mixture, Under a nitrogen atmosphere, react in an oil bath at 100°C for 10 hours, cool down to room temperature, wash the precipitate with excess deionized water for 5 times, and dry it in vacuum at 75°C for 24 hours to obtain a light brown precipitate, which is the linear polymer I (PEP);

[0037] b. Weigh the linear polymer I (PEP) in step (a), dissolve it in DMF and put it into a three-necked flask, slowly add 0.1 g of methylimidazole dropwise under a nitrogen atmospher...

Embodiment 2

[0048] According to the method of the present invention, a masterbatch of explosion-proof material with good low-temperature resistance and barrier performance is prepared, and the operation steps are as follows:

[0049] (1) Preparation of polyolefin modifier

[0050] a. Weigh 13.8g of phthalic anhydride and dissolve it in 40ml of DMF, mix uniformly at 65°C in a nitrogen atmosphere, then slowly add 20ml of ethylene glycol and 8ml of epichlorohydrin equal to the molar weight of phthalic anhydride to the above mixture, Under nitrogen atmosphere, react in an oil bath at 110°C for 9 hours, cool down to room temperature, wash the precipitate with excess deionized water for 3 times, and dry it in vacuum at 75°C for 24 hours to obtain a light brown precipitate, which is the linear polymer I (PEP);

[0051] b. Weigh the linear polymer I (PEP) in step (a), dissolve it in DMF and put it into a three-necked flask, slowly add 0.25 g of methylimidazole dropwise under a nitrogen atmosphere...

Embodiment 3

[0062] According to the method of the present invention, a masterbatch of explosion-proof material with good low-temperature resistance and barrier performance is prepared, and the operation steps are as follows:

[0063] (1) Preparation of polyolefin modifier

[0064] a. Weigh 15.3g of phthalic anhydride and dissolve it in 50ml of DMF, mix uniformly at 70°C in a nitrogen atmosphere, then slowly add 25ml of ethylene glycol and 10ml of epichlorohydrin equal to the molar weight of phthalic anhydride to the above mixture, Under nitrogen atmosphere, react in an oil bath at 120°C for 8 hours, cool down to room temperature, wash the precipitate with excess deionized water 4 times, and dry it in vacuum at 75°C for 24 hours to obtain a light brown precipitate, which is the linear polymer I (PEP);

[0065] b. Weigh the linear polymer I (PEP) in step (a), dissolve it in DMF and put it into a three-necked flask, slowly add 0.5 g of methylimidazole dropwise under a nitrogen atmosphere, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com