A kind of high-strength rebar and its preparation method

A technology of rebar and billet, applied in coating, anti-corrosion coating, metal material coating process, etc., can solve problems such as affecting the gripping force of rebar and concrete, affecting the quality of rebar using engineering, and not building and storing rebar. , to achieve the effect of improving hardness, strengthening prevention, and preventing rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

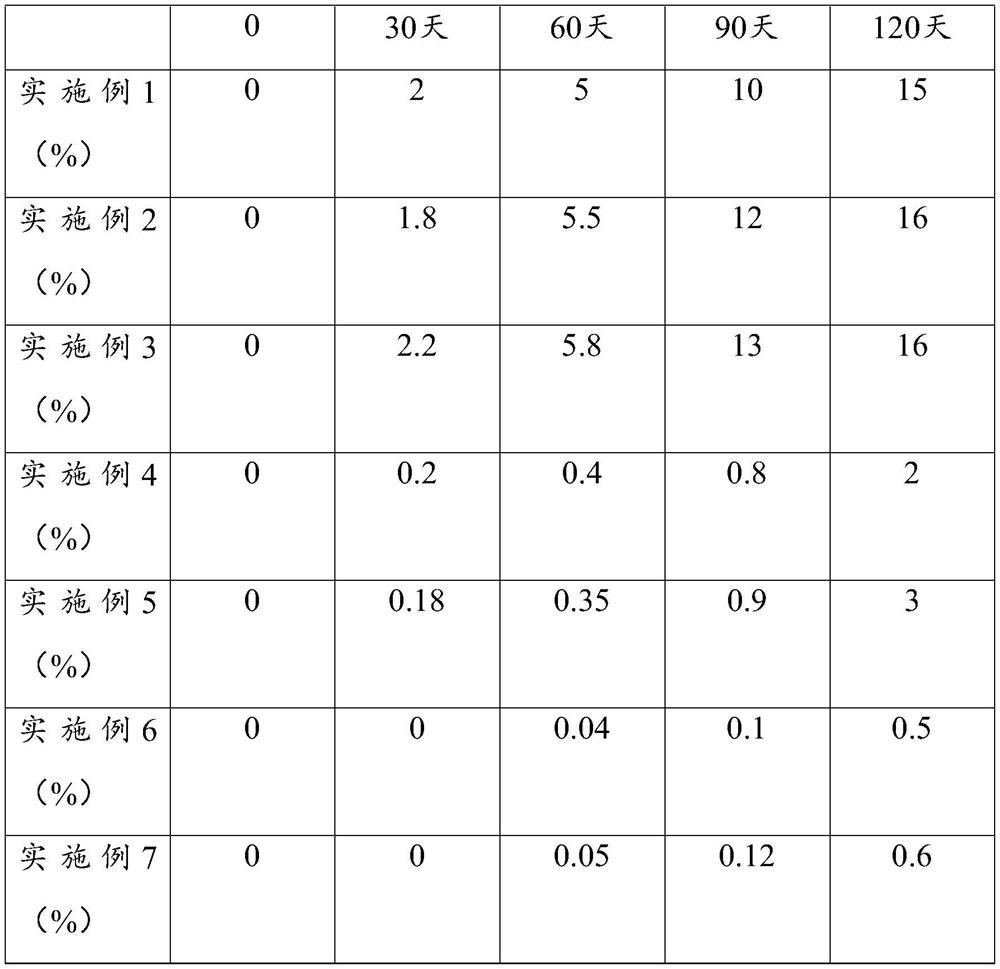

Examples

preparation example Construction

[0034] This specific embodiment also includes the preparation method of the above-mentioned threaded steel, including preparing the threaded steel body, and the specific steps are as follows:

[0035] S1. Melting each component into molten steel according to the ratio, and then blowing argon, increasing nitrogen, and blowing argon; continuously casting the molten steel through a continuous casting machine to obtain a billet;

[0036] S2. Rolling the billet into a rebar body, the rolling conditions are billet heating temperature 1100-1300°C, billet starting rolling temperature 1100°C-1150°C, finishing rolling temperature 1000°C±20°C, finishing rolling temperature 900°C-950°C;

[0037] S3. Cool the rebar body obtained in step S2 to 700-750°C and keep it warm for 1-2h, then cool it down to 500-650°C and keep it warm for 0.5-1h;

[0038] S4, then raise the temperature to 700-750°C and keep it warm for 1-2h, then cool down to 500-650°C and keep it warm for 0.5-1h, repeat this step...

Embodiment 1

[0044]A high-strength rebar, including a rebar body, in terms of mass percentage, the rebar body includes the following components:

[0045] 0.33% carbon, 0.40% silicon, 0.05% aluminum, 0.02% titanium, 0.02% nitrogen, 0.2% vanadium, 0.05% manganese, 0.03% phosphorus, 0.005% sulfur, balance iron.

[0046] The specific preparation steps of the rebar body are as follows:

[0047] S1. Melting each component into molten steel according to the ratio, and then blowing argon, increasing nitrogen, and blowing argon; continuously casting the molten steel through a continuous casting machine to obtain a billet;

[0048] S2. Rolling the billet into a rebar body, the rolling conditions are billet heating temperature 1300°C, billet start rolling temperature 1100°C, finish rolling temperature 1000°C±20°C, finish rolling temperature 900°C;

[0049] S3. Cool the rebar body obtained in step S2 to 750°C and keep it warm for 2h, then cool it down to 650°C and keep it warm for 1h;

[0050] S4. A...

Embodiment 2

[0052] A high-strength rebar, including a rebar body, in terms of mass percentage, the rebar body includes the following components:

[0053] 0.25% carbon, 0.35% silicon, 0.1% aluminum, 0.04% titanium, 0.017% nitrogen, 0.1% vanadium, 0.1% manganese, 0.02% phosphorus, 0.08% sulfur, balance iron.

[0054] The specific preparation steps of the rebar body are as follows:

[0055] S1. Melting each component into molten steel according to the ratio, and then blowing argon, increasing nitrogen, and blowing argon; continuously casting the molten steel through a continuous casting machine to obtain a billet;

[0056] S2. Rolling the billet into a rebar body, the rolling conditions are billet heating temperature 1100°C, billet start rolling temperature 1100°C, finish rolling temperature 1000°C±20°C, finish rolling temperature 950°C;

[0057] S3. Cool the rebar body obtained in step S2 to 700°C and keep it warm for 1h, then cool it down to 500°C and keep it warm for 0.5h;

[0058] S4, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com