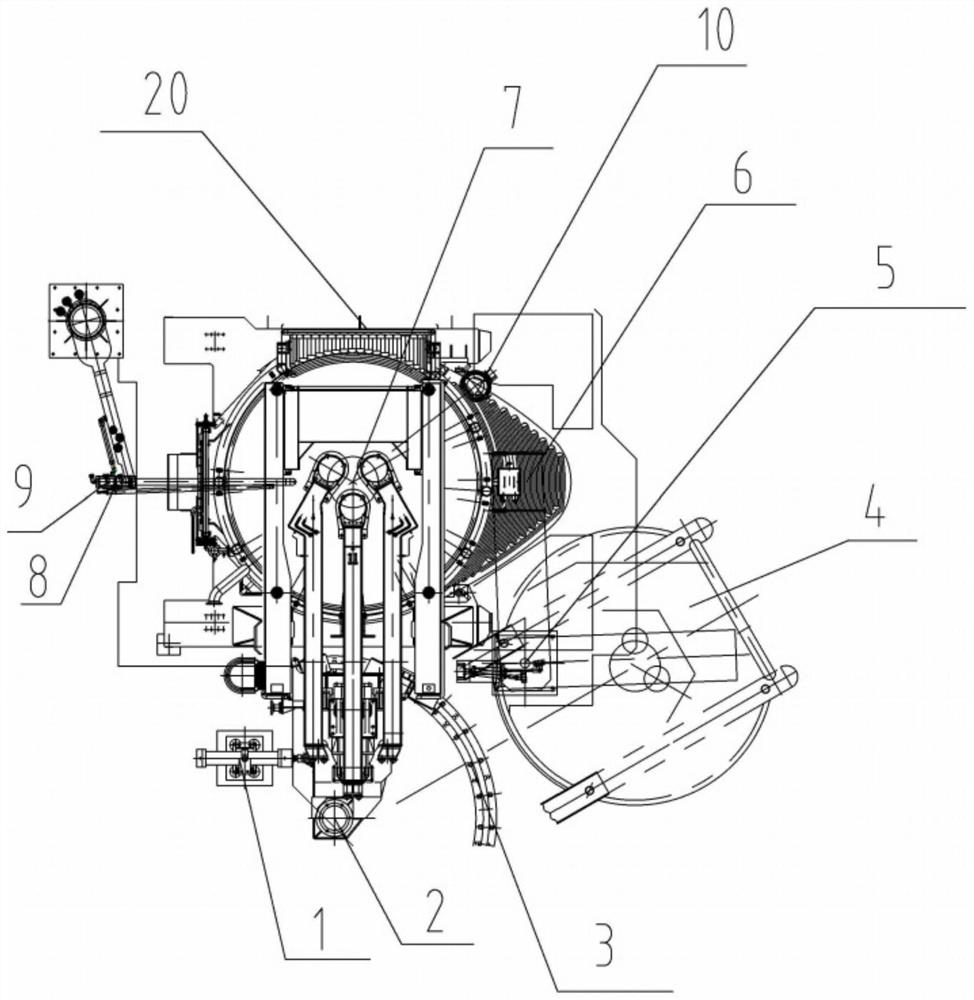

Electric furnace system

A technology of electric furnace and furnace cover, applied in the field of electric furnace, can solve the problems of continuous preheating of unfavorable charge, slow tapping time and high production cost, and achieve the effects of reducing non-energization time, improving preheating effect and stabilizing arc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

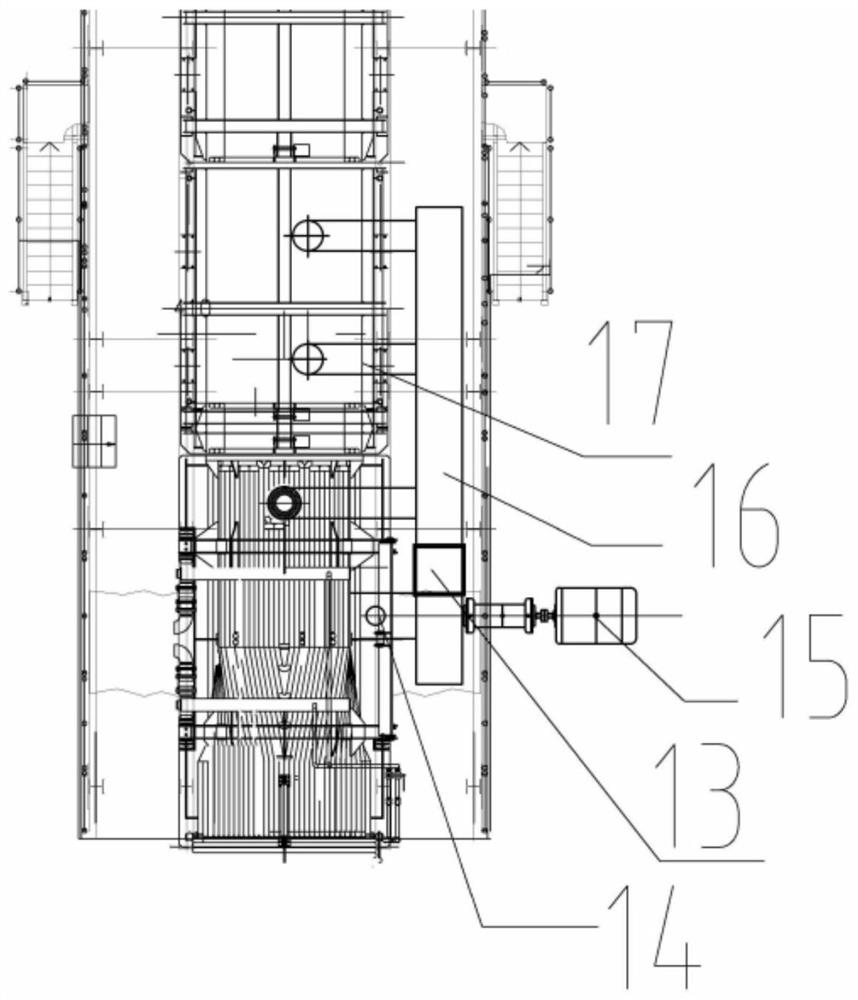

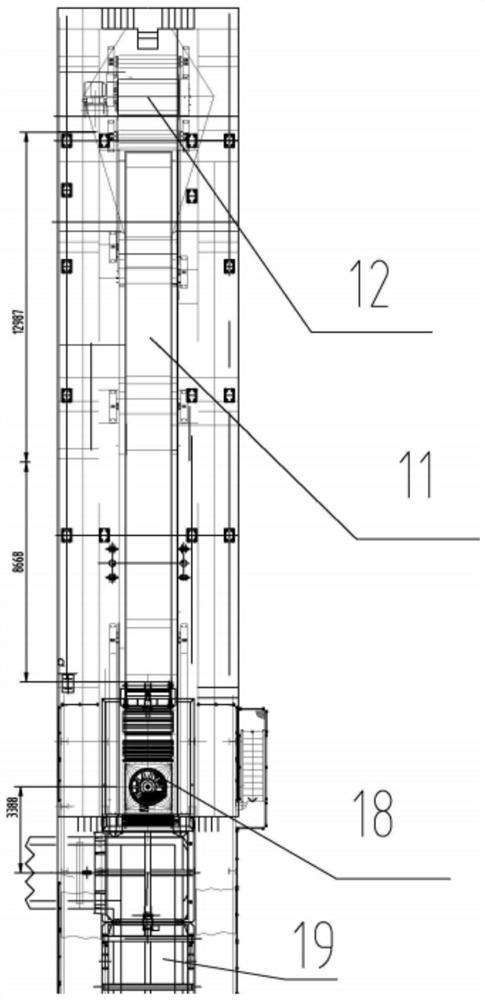

Method used

Image

Examples

Embodiment 1

[0072] A steelmaking process, comprising the steps of:

[0073] S1: The scrap steel raw materials are hoisted into the vibrating feeder by the crane;

[0074] S2: The vibrating feeder transports the steel scrap raw material from the feeding bin to the electric furnace body;

[0075] S3: Preheat the furnace body through the furnace door oxygen lance and the furnace arm oxygen lance, and use the high-temperature fan to preheat the electric furnace body with the waste heat exhausted from the electric furnace body;

[0076] S4: The preheated steel scrap raw material vibrates and enters the circuit furnace body for melting and smelting;

[0077] S5: During the smelting process, lime is first added from the alloy feed port, and then alloy conditioning ingredients are added;

[0078] S6, when the temperature of the molten steel in the furnace body of the electric furnace is 15-70°C, the shaking furnace is tilted to tap steel.

[0079] Wherein in the step S5, lime is first added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com