Intelligent glasses wearing system applied to power plant equipment inspection

An equipment inspection and power plant technology, applied in the field of smart wearing glasses system, can solve the problems of workers forgetting to check equipment, unable to respond effectively, and low efficiency, so as to improve the efficiency of inspection, improve the speed of timely response, and improve the quality of inspection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

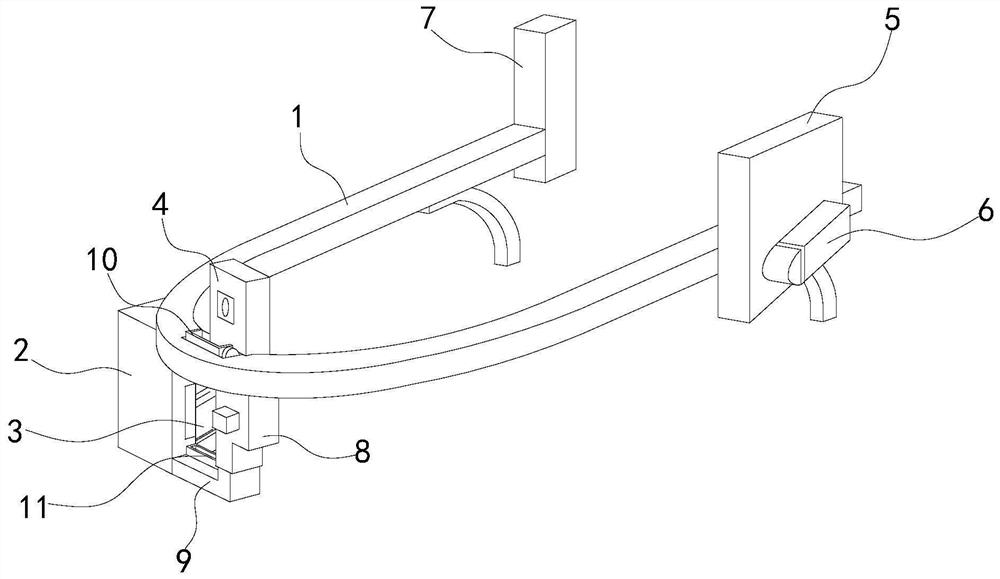

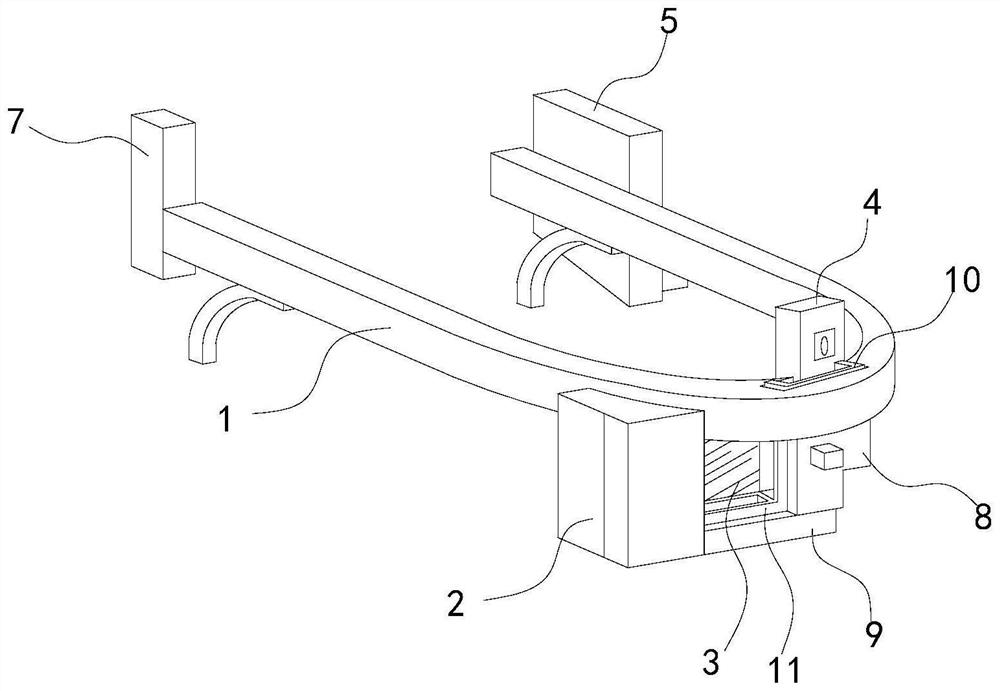

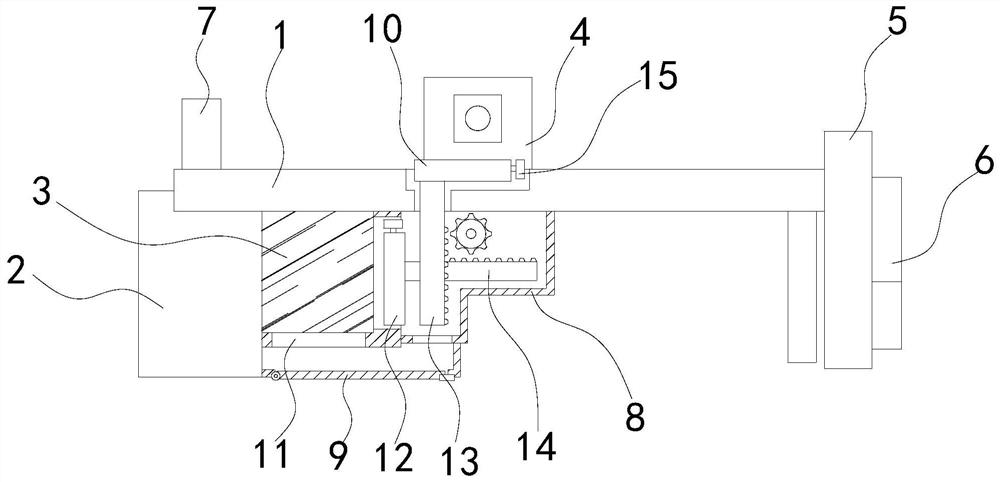

[0037] see Figures 1 to 7 , a schematic plan view and a three-dimensional structure view of a smart wearing glasses system applied to power plant equipment inspection.

[0038] An intelligent wearing glasses system for equipment inspection in power plants, comprising a glasses main body 1, a display device 2, a miniature camera 4, a microcomputer motherboard 5, a voice device 6, and an energy storage battery 7;

[0039] The miniature camera 4 is arranged on the front upper end of the glasses main body 1;

[0040] The microcomputer motherboard 5 is arranged on the back end side of the glasses main body 1, and is connected to the display device 2, the micro camera 4, the voice device 6, and the energy storage battery through the cables inside the glasses body 1 to transmit signals. The microcomputer motherboard 5 is provided with WIFI module;

[0041] Voice device 6 is plugged in the outside of the microcomputer main board;

[0042] The display device 2 is arranged on the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com