Coal-fired unit high-temperature superheater wall temperature prediction neural network model

A technology for predicting neural networks and high-temperature superheaters. It is applied in the direction of biological neural network models, predictions, and neural architectures. It can solve problems that do not meet online calculations, backward prediction structures, and many boundary parameters, so as to improve training and generalization accuracy. , Precise prediction results, reducing the effect of supervision work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

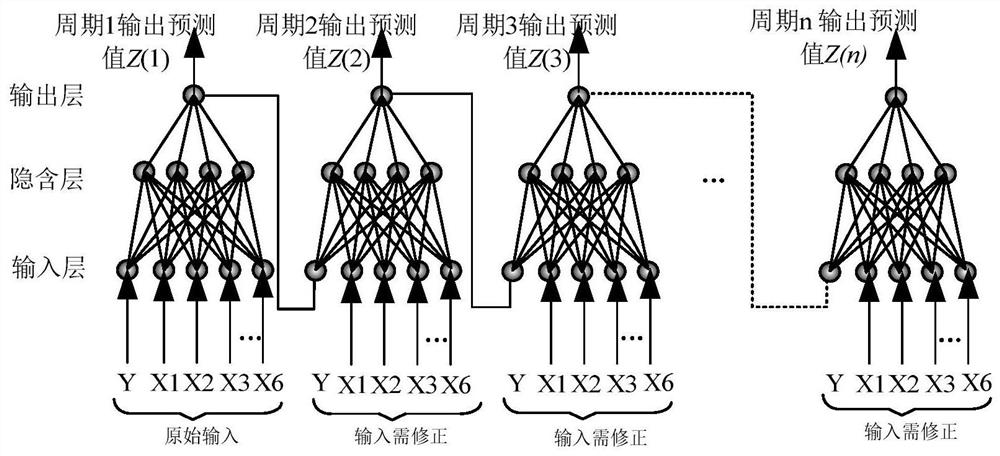

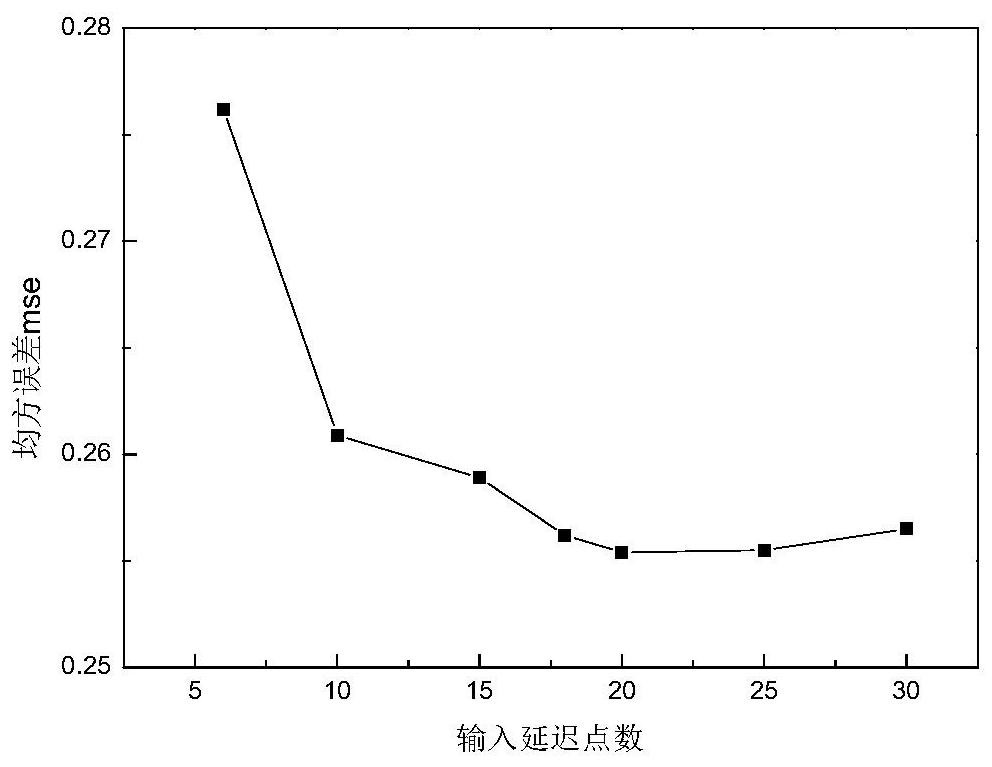

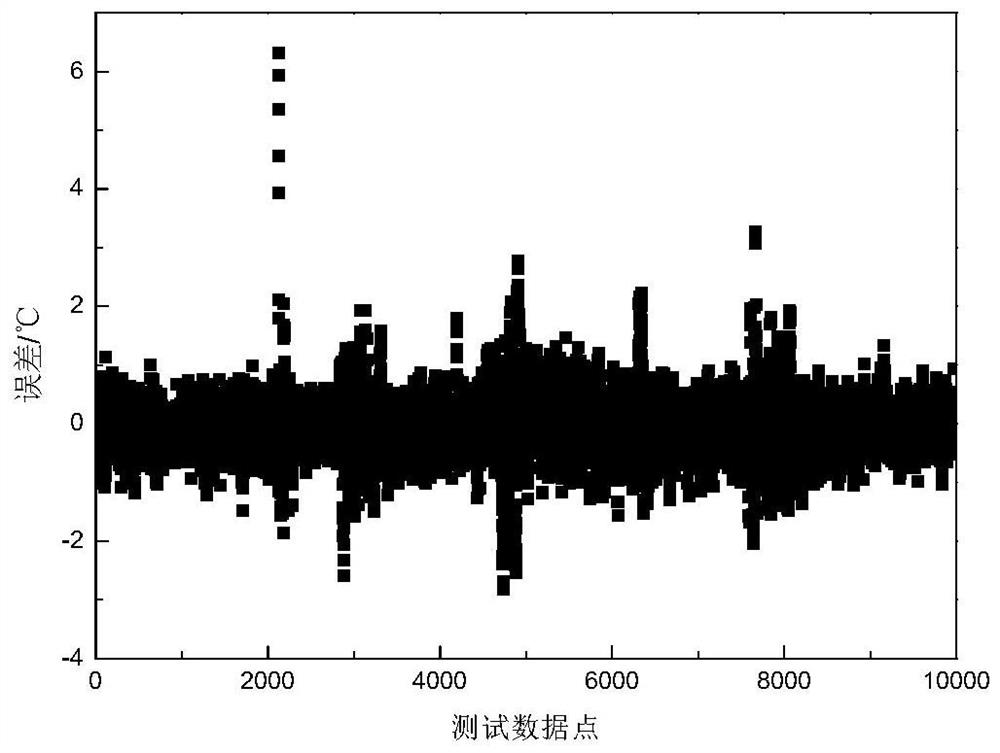

[0035] A 660MW unit in a power plant uses an ultra-supercritical once-through boiler with a single furnace, one intermediate reheating, and a double flue structure at the rear. Comprehensively analyze the factors affecting the wall temperature of the high temperature superheater at a certain point, and select the load of the unit, the main steam flow rate, the average wall temperature of the left and right side wall superheaters, the amount of secondary desuperheating water on the left and right sides, and the maximum wall temperature of the high temperature superheater as the neural network model input layer. The data sampling period is 10s, and six neural network models are used to sequentially predict the output results after 60s, so as to realize the advanced dynamic prediction of the maximum wall temperature. That is, the predicted value after 10s is used as the historical input of the maximum wall temperature of the second neural network screen, so as to complete the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com