Model prediction current control method for dual-motor torque synchronization system

A synchronous system and model prediction technology, applied in multiple motor speed/torque control, motor control, motor generator control, etc., can solve problems such as inability to determine the optimal value, inability to take into account various indicators, and wrong switch combination status

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

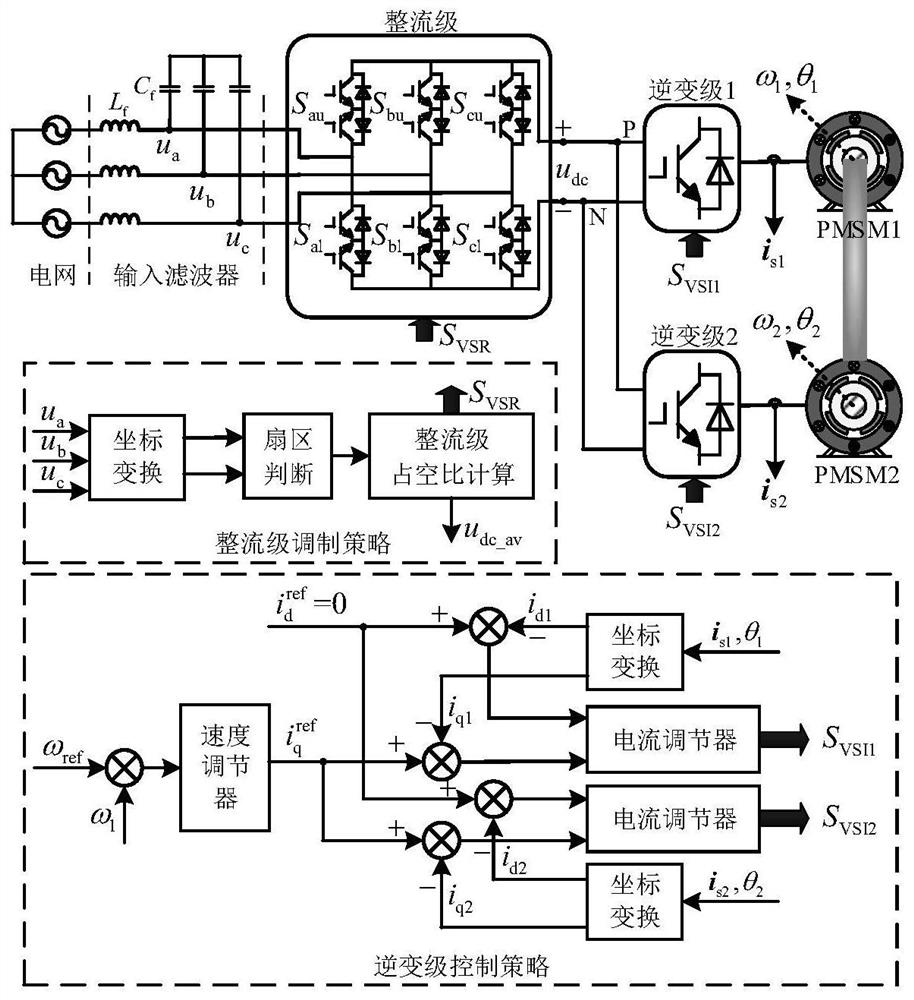

[0076] Specific embodiments of the present invention include the following steps:

[0077] 1) Introduce the dual motor torque synchronization error ε as a state variable into the prediction process, integrate the current controllers of the two motors into an MPCC controller, simplify the current inner loop control structure, and realize dual motors through state prediction and rolling optimization. The closed-loop control of the torque synchronization error improves the torque synchronization performance of the dual-motor system.

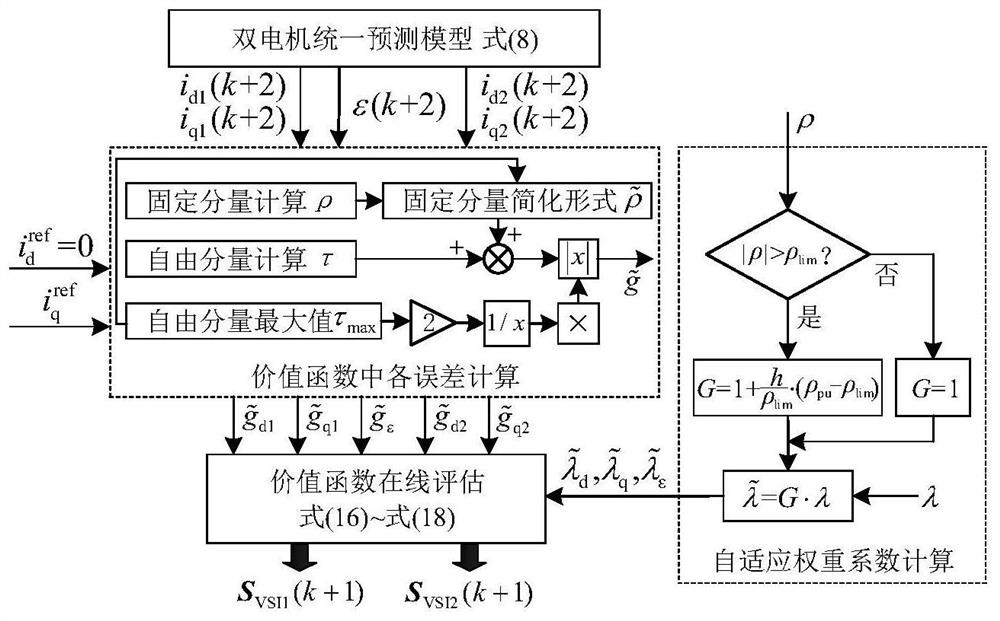

[0078] Taking the d, q axis current and torque synchronization errors of the two motors as the state variables, and considering the delay compensation, a unified prediction model for the two motors is established:

[0079] X(k+2)=G(k+1) X(k+1)+F U(k+1)+K D(k+1) (8)

[0080] In the formula, state vector X(k+1)=[i d1 (k+1)i q1 (k+1)i d2 (k+1)i q2 (k+1)ε(k+1)] T ;Input vector U(k+1)=[u d1 (k+1)u q1 (k+1)u d2 (k+1)u q2 (k+1)] T ;Transfer vect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com