Unimolecular transistor

A transistor and single-molecule technology, applied in transistors, electric solid-state devices, semiconductor devices, etc., can solve problems such as upper limit of working speed, increased power consumption, and increased cut-off leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

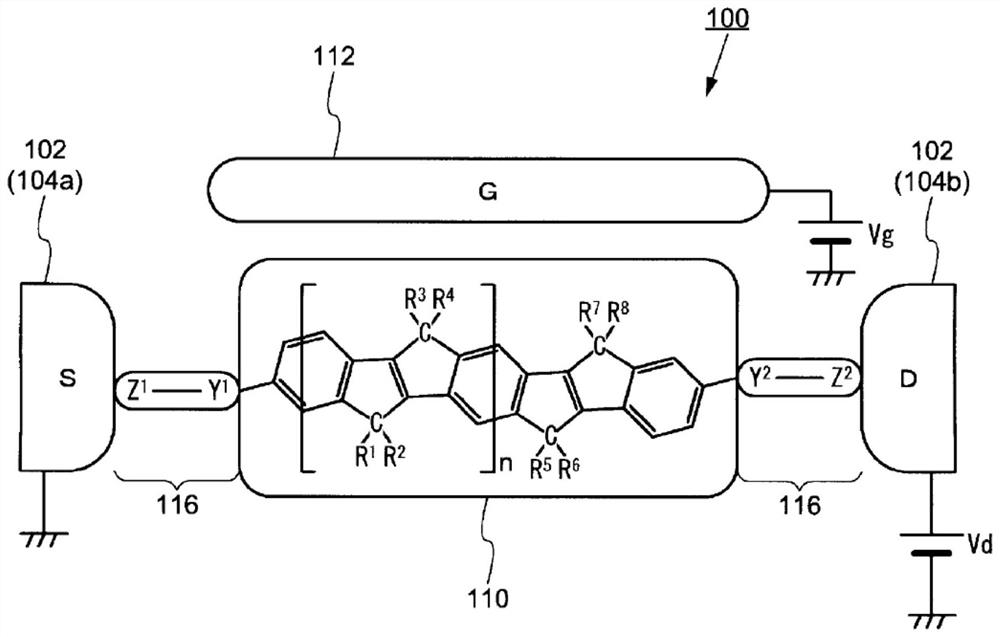

[0163] 4 Manufacturing Example of Single Molecular Transistor

[0164] The following is a fabrication example of a single molecular transistor. The monomolecular transistor fabricated in this example has the same Figure 6A , Figure 6B , Figure 6C The same configuration as the single-molecule transistor described in .

[0165] 4-1 Fabrication of Nanogap Electrodes

[0166] The steps of preparing the nanogap electrodes include the steps of making platinum electrodes as the first electrode layer 106a and the second electrode layer 106b, and growing gold particles on the platinum electrodes as the first metal particles 108a and the second metal particles by electroless gold plating. Step 108b.

[0167] 4-1-1 Manufacture of Platinum Electrode

[0168] As a substrate for producing a platinum electrode, a silicon wafer having a silicon oxide film formed on its surface was used. The substrate is cleaned by ultrasonic cleaning using acetone and ethanol, ultraviolet (UV) ozone...

Embodiment 2

[0229] This example shows the characteristics of a single-molecule transistor using a different functional molecule from Example 1. In this embodiment, the structure of the unimolecular transistor is the same as that of the first embodiment. The fabrication of the nanogap electrodes was carried out according to the same procedure as that of the first embodiment. As a functional molecule, a carbon-bridged p-phenylene vinylene oligomer (COPV6(SH) 2 ). The steps of introducing functional molecules into the nanogap electrodes are the same as those in the first embodiment.

[0230] 6-1 carbon bridge p-phenylene vinylene oligomer (COPV6(SH) 2 )Structure

[0231] Carbon-bridged p-phenylene vinylene oligomer (COPV6(SH) 2 ) structure is represented by formula (6).

[0232] [chemical formula 6]

[0233]

[0234] R 1 to R 3 Can be the same or different. R 1 to R 3 May be the same or different aryl substituents which may be substituted. The aryl group is preferably a hydro...

Embodiment 3

[0258] This example shows a single-molecule transistor using both ends of a silicon-bridged quinone-type condensed oligomeric silanol derivative (Si-2×2) as a rigid π-conjugated molecule containing silicon. Contains -O-(CH 2 ) n Single molecules of SH serve as functional molecules.

[0259] 7-1 Fabrication method of single molecular transistor

[0260] A nanogap electrode was fabricated in the same manner as in Example 1. The fabricated nanogap electrodes were impregnated in hexanethiol (C 6 SH) solution, a self-assembled monolayer (SAM: Self-Assembled Monolayer) was prepared. When the surface coverage of the SAM is intentionally reduced by shortening the immersion time, the introduction rate of functional molecules having linking groups and anchoring groups is increased.

[0261] In addition, the SAM is effective for fabricating a bridge-structured unimolecular transistor in which a functional molecule having a linking group and an anchoring group at both ends is chemicall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Conductance | aaaaa | aaaaa |

| Gap length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com