A recycling process and recycling system for waste water and residue of concrete mixing plant

A technology of concrete waste and concrete, which is applied in the direction of mixer, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., and can solve the problem that waste slurry water cannot be completely consumed and disposed of, waste slurry water consumption, environmental pollution, etc. problems, to achieve resource utilization, reduce pollution, and avoid excessive load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

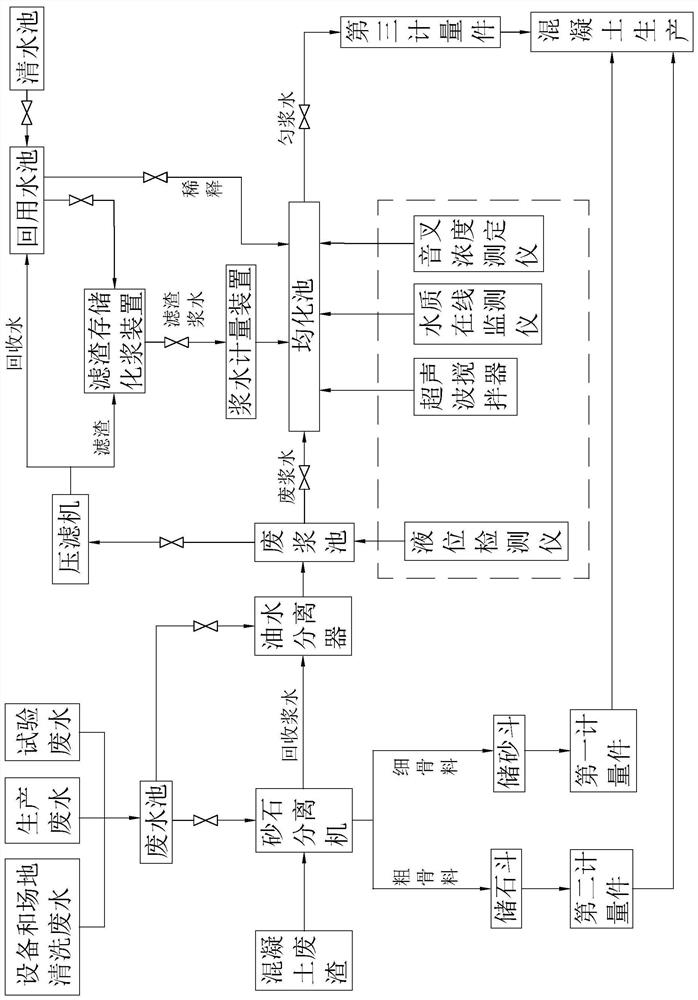

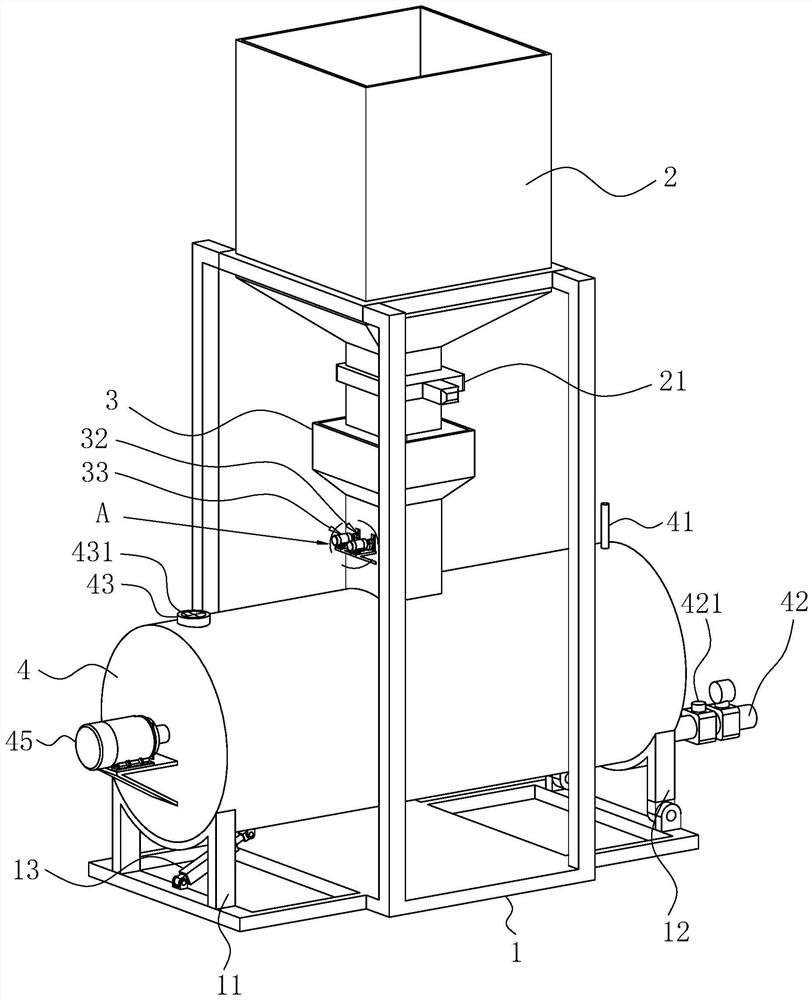

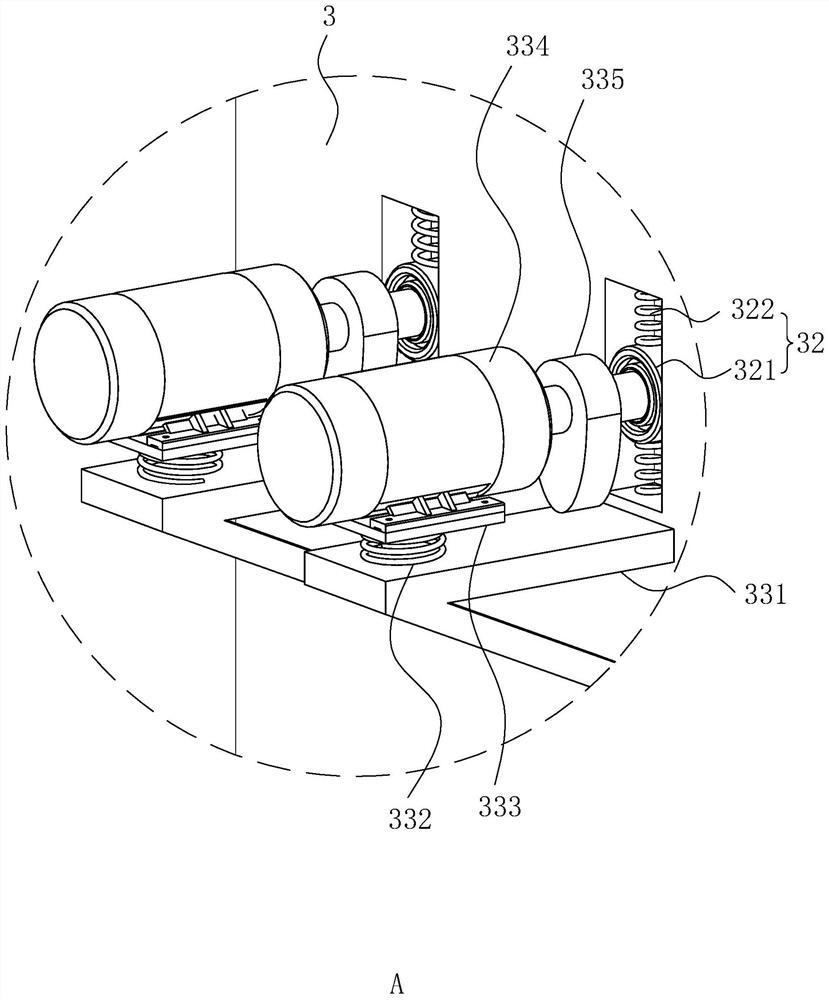

[0049] refer to figure 1 , The waste water and residue reuse system of the concrete mixing plant includes a sand and stone separation unit, a waste slurry water collection and monitoring unit, a waste slurry water control unit, a reuse unit, and a control unit; the sand and stone separation unit includes a waste water tank and a sand and stone separator; the waste slurry The water collection and monitoring unit includes an oil-water separator, a waste slurry tank, a homogenization tank, a stirring device, and a slurry water monitoring device; the waste slurry water control unit includes a liquid level monitoring device, a filter press, a reuse pool, a filter residue storage slurry device, and Slurry water metering device; the recycling unit includes a sand storage bucket, a stone storage bucket and a metering device. The metering device includes a first metering piece matched with the sand storage bucket, a second metering piece matched with the stone storage bucket, and a homo...

Embodiment 2

[0067] This embodiment discloses a process for reusing waste water and slag from a concrete mixing plant, which differs from the process for reusing waste water and slag in a concrete mixing plant disclosed in Example 1 in that:

[0068] S23. Use an online water quality monitor to monitor the pH value, sulfate ion concentration, and chloride ion concentration of the homogenate water, and use a tuning fork concentration detector to monitor the concentration of the homogenate water;

[0069] When the monitored value of the homogenized water is detected to be higher than the standard value, the control unit gets feedback, controls the reuse water pool to supply water to the homogenized tank, and dilutes the homogenized water in the homogenized tank until the monitored value of the homogenized water is adjusted below the standard value;

[0070] During the peak production period of the concrete mixing plant, when the accumulation rate of the filter residue is greater than the recy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com