Clay-containing blocky material anhydrous desliming machine

A technology for lumps and clay, which is applied in the field of anhydrous desliming machines for lumps, can solve the problems of difficult to meet the processing and production of bauxite, high cost of desliming, coal-burning pollution, etc., and prevent the soil from being poor in mines The effect of reducing energy consumption, reducing negative impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

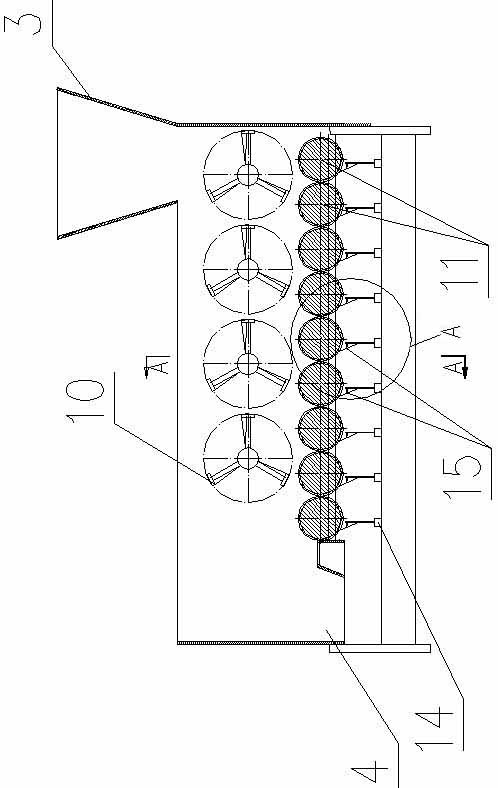

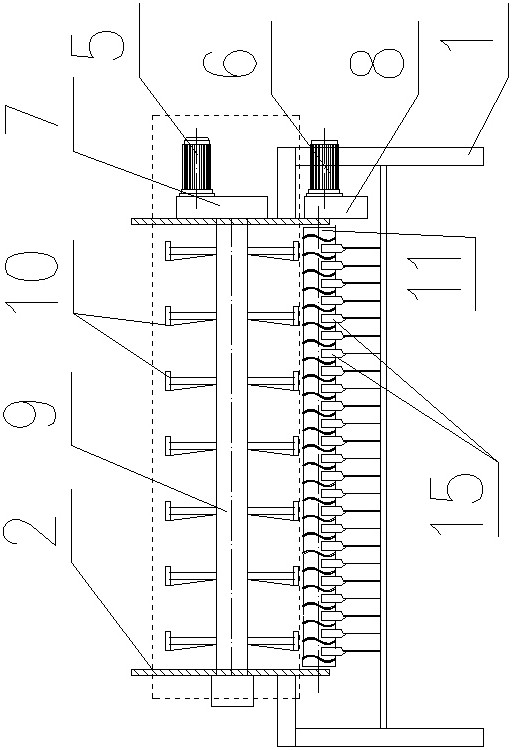

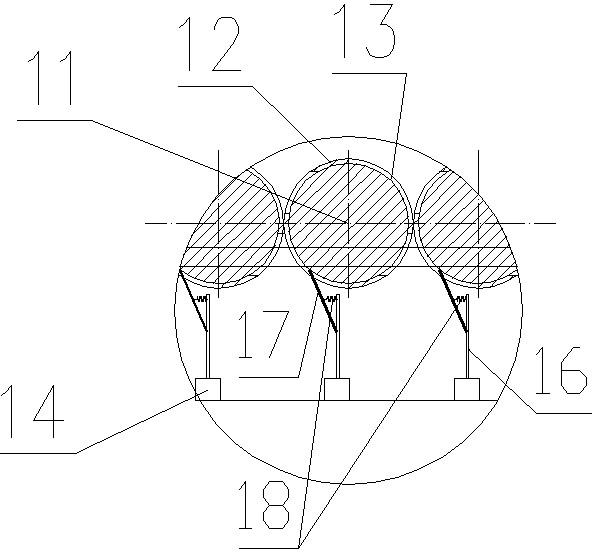

[0032] like Figure 1 to Figure 4 As shown, the anhydrous deslimer of clay-containing lumps of the present invention comprises a frame 1, and the frame 1 is provided with a desliming tank 2 with an open lower end surrounded by a vertical plate, and the moving direction of the material is the front. In the direction, the rear side of the desliming tank 2 is connected upwardly with a feed port 3, and the front side of the desliming tank 2 is downwardly provided with a discharge port 4;

[0033] The desilting tank 2 is provided with a material turning device for moving the material from the feed port 3 to the discharge port 4. A mud scraping roller group is arranged below the material turning device and adjacent to the material turning device. Each scraper in the mud scraping roller group The axial ends of the mud roller are installed on the frame 1 through bearings; the bearings are conventional technology, not shown in the figure.

[0034] The frame 1 is equipped with a power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com