A fept@c composite nanomaterial based on mof and its application

A technology of composite nanomaterials and composite materials, which is applied in the field of electrocatalytic fuel cell preparation, can solve problems such as weak conductivity, and achieve the effects of improving conductivity, improving catalytic stability, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

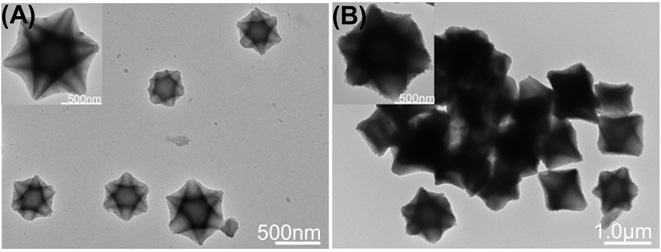

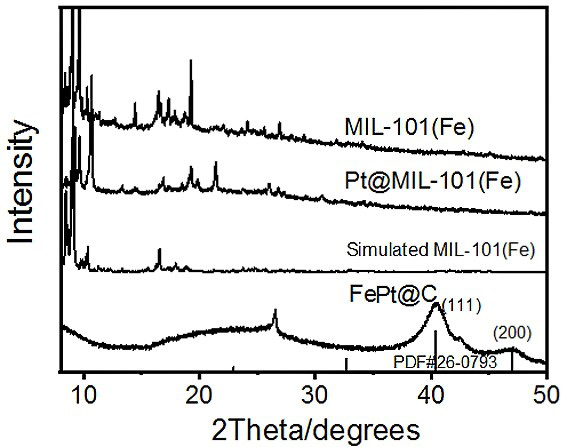

[0027] (1) Weigh 0.675 g of ferric chloride (2.45 mmol) and 0.206 g of terephthalic acid (1.24 mmol), dissolve them in 15 mL of N,N-dimethylformamide, and sonicate for 15 min to make them completely Dissolve; then transfer the fully dissolved reactant to a 25 mL polytetrafluoroethylene reactor, raise the temperature of the muffle furnace to 110 °C, and react for 20 h; after the autoclave is cooled to room temperature, the reaction product is centrifugally filtered , washed with DMF and absolute ethanol for three times, and finally dried under vacuum at 70° C. overnight to obtain MIL-101(Fe).

[0028] (2) Mix 0.3 g of MIL-101(Fe) prepared in step (1) with 0.0498 g of PVP and 135 mL of absolute ethanol, and add 7.0 mL of 0.016 g / L chloroplatinic acid solution drop by drop , after stirring for 30 min, heated to reflux at 100 °C for 3 h under continuous stirring to synthesize Pt@MIL-101(Fe) composites.

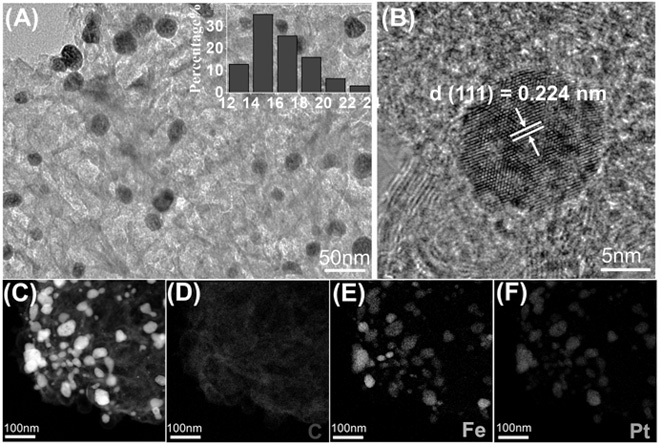

[0029] (3) The Pt@MIL-101(Fe) composite material prepared in step (2) was gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com