Primary frequency modulation dynamic cooperative control method of turbine regulating system

An adjustment system and collaborative control technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems that the primary frequency regulation technology is difficult to meet the requirements, and the thermal efficiency of the unit and the performance of primary frequency regulation are difficult to balance, so as to improve the working ability. Taking energy consumption and safety into account

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

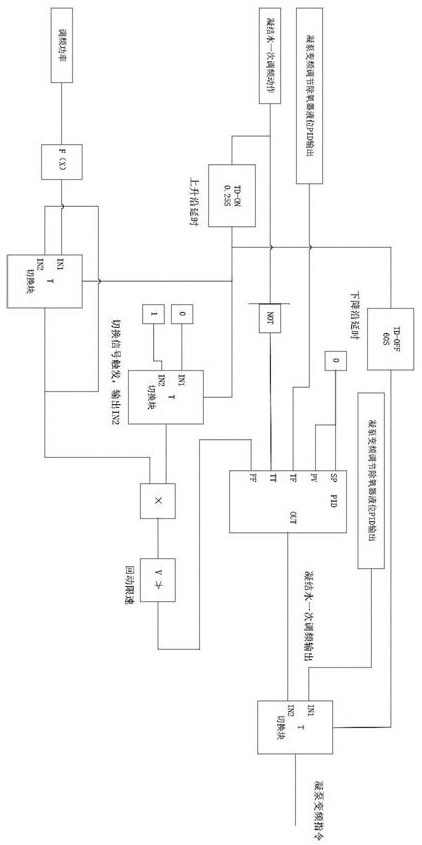

Image

Examples

Embodiment Construction

[0046] A dynamic coordinated control method for primary frequency modulation of a steam turbine regulation system, including frequency conversion and throttling of a condensate pump, and frequency modulation steps, specifically including the following steps:

[0047] S1. Combining the frequency conversion throttling and frequency modulation step technology of the condensing pump, through the test, capture the performance curve of the condensing pump frequency conversion throttling and frequency modulation step technology under various working conditions, dynamically evaluate the safety and economy of the unit, and take into account Unit energy consumption and frequency regulation performance, coordinately adjust its regulation depth;

[0048] S2. Adopt condensate water throttling technology to quickly recover or release part of the steam medium used for low heating and heat exchange, increase or decrease the heat energy used for steam turbine work, quickly change the load of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com