Corn silaging method and corn silage

A corn silage and corn technology, applied in the agricultural field, can solve the problems that the protein content and starch content cannot meet the silage quality standard, restrict the development of animal husbandry, increase the cost of silage, etc., and achieve sustainable and healthy development, high conversion rate, and reduced production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

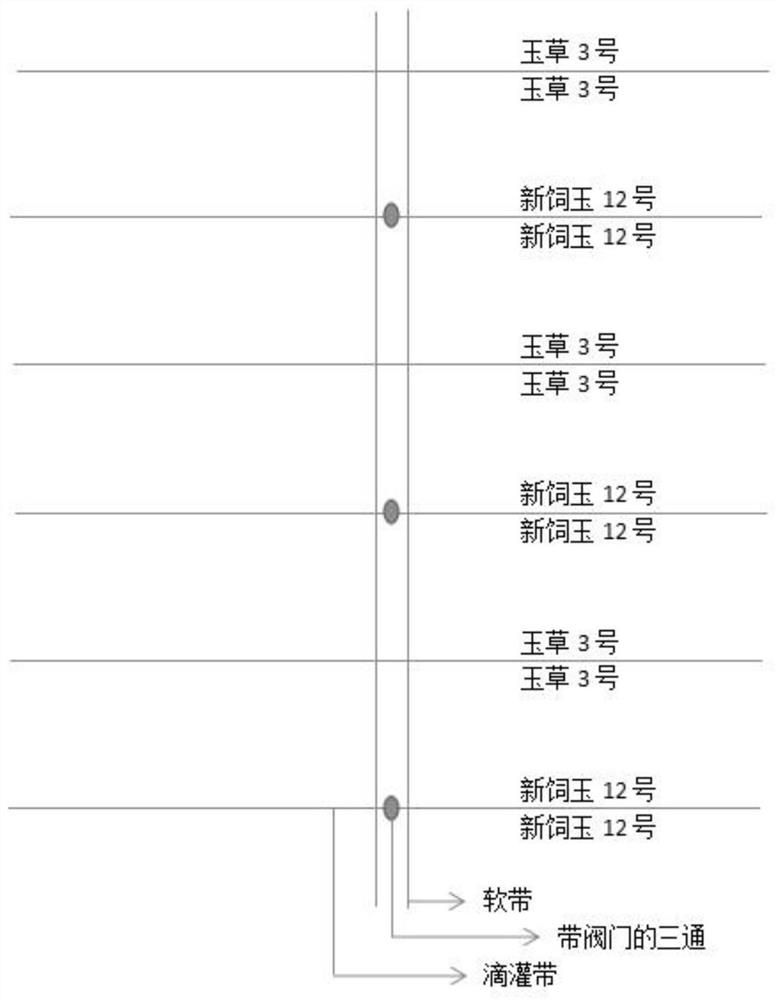

[0029] Cultivation of Yucao No.3 Maize and Xinsiyu No.12 Maize

[0030] 1. Preparation before broadcasting

[0031] Location: Land No. 20 of Comprehensive Experimental Field of Xinjiang Academy of Agricultural Sciences, with an area of 100 mu.

[0032] Fine soil preparation: water in time after the harvest of rapeseed, wheat, potato plots or previous crops of leguminous crops, plow to a depth of 35-40cm, rake in time, level the land, and shallow plow before sowing, so as to achieve the top empty and bottom solid.

[0033] Seed selection: 10 days before sowing, choose a sunny day to dry the seeds to increase the germination rate, and manually select the seeds to remove small, broken, and diseased seeds.

[0034] 2. Timely and appropriate sowing

[0035] 2.1 Sowing time: May 1

[0036] 2.2 Seed rate

[0037] The sowing rate of Yucao No. 3 is 0.7kg / mu, and that of Xinsiyu No. 12 is 1.2kg / mu. The row spacing of the two varieties is 50cm, the plant spacing is 35cm, and the nu...

Embodiment 2

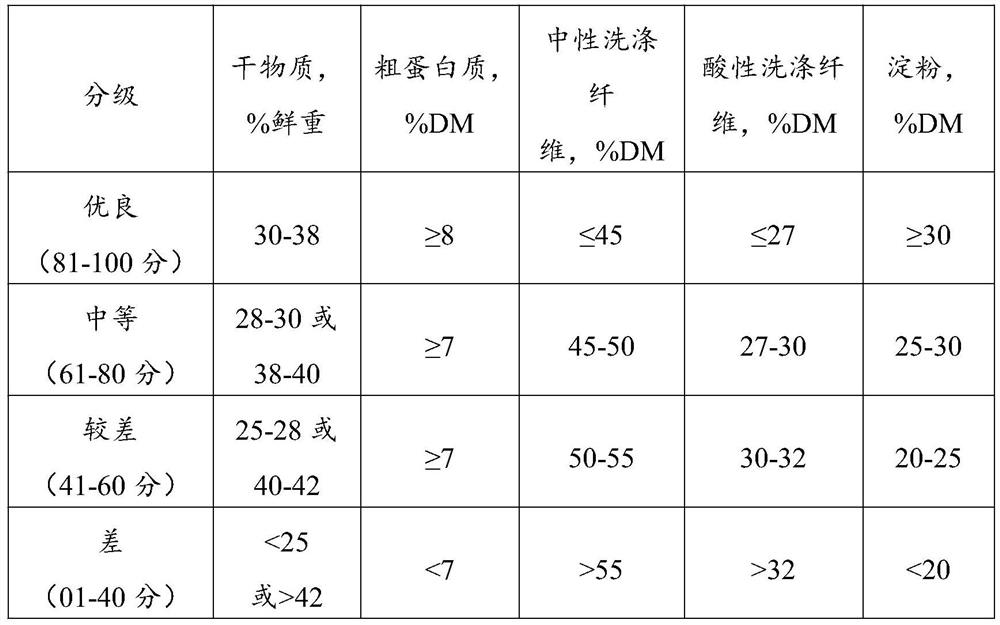

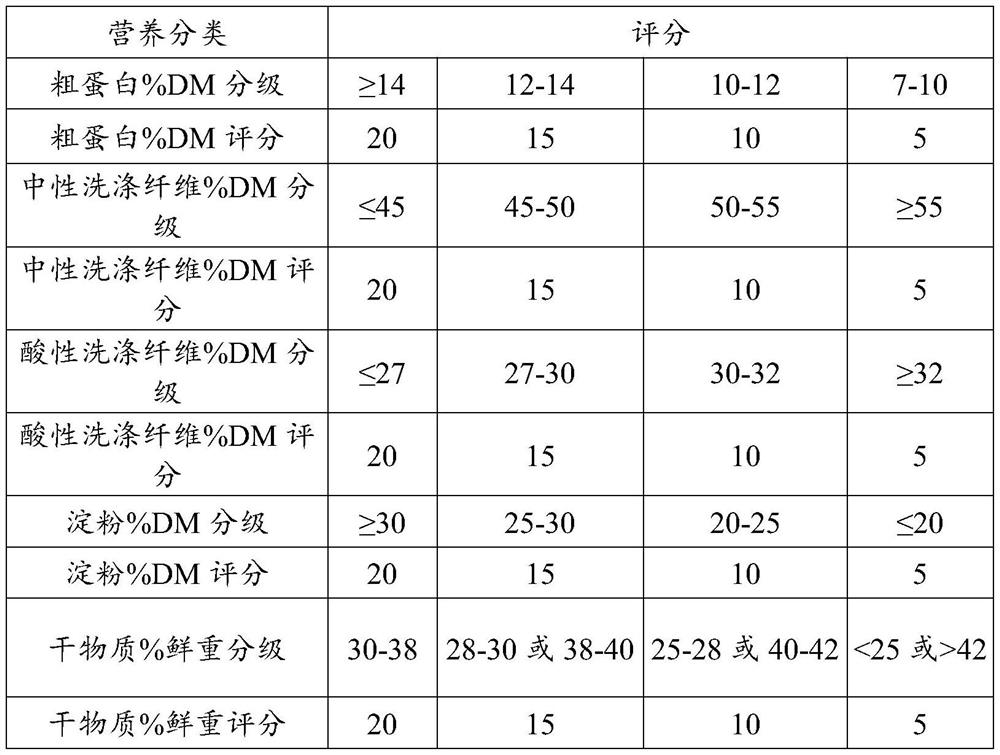

[0072] The steps are the same as those in Example 1, except that the recipe uses: 50% Yucao No. 3 + 50% Xinsiyu 12 fungicide for silage, the yield of silage fresh grass obtained per mu is 7.4-7.7t, dry sample Protein content: 13.66% DM, acid detergent fiber 29.13% DM, neutral detergent fiber 46.99% DM.

Embodiment 3

[0074] The steps are the same as those in Example 1, except that the recipe uses: 70% Yucao No. 3 + 30% Xinsiyu 12 fungicide for silage, and the yield of silage fresh grass obtained per mu is 7.3-7.6t. Protein content: 13.96% DM, acid detergent fiber 31.86% DM, neutral detergent fiber 49.32% DM.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com