Process method for cutting quartz crystal wafers through diamond wires

A technology of diamond wire cutting and quartz wafers, applied in stone processing equipment, fine working devices, working accessories, etc., can solve the problems of oil sand environmental pollution, large tolerances of wafer thickness and angle, and long time-consuming, etc., to reduce production Effects of cost, tight wafer thickness and angle tolerances, avoidance of contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

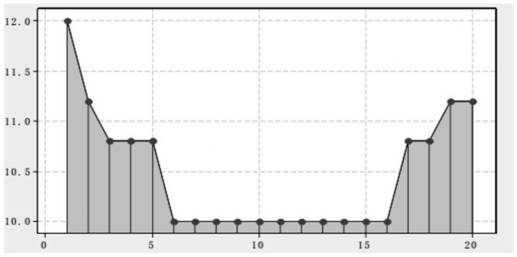

[0022] The invention provides a process method for cutting quartz wafers by diamond wire, which is matched with CNC multi-wire cutting equipment, and the workpiece feed speed segmentation mode is created in the operation program of CNC multi-wire cutting equipment, and the numerical control multi-wire cutting The feed stroke of the worktable of the equipment is divided into several sections. During the cutting process, the feed speed of the worktable is controlled for different sections of the feed stroke of the worktable.

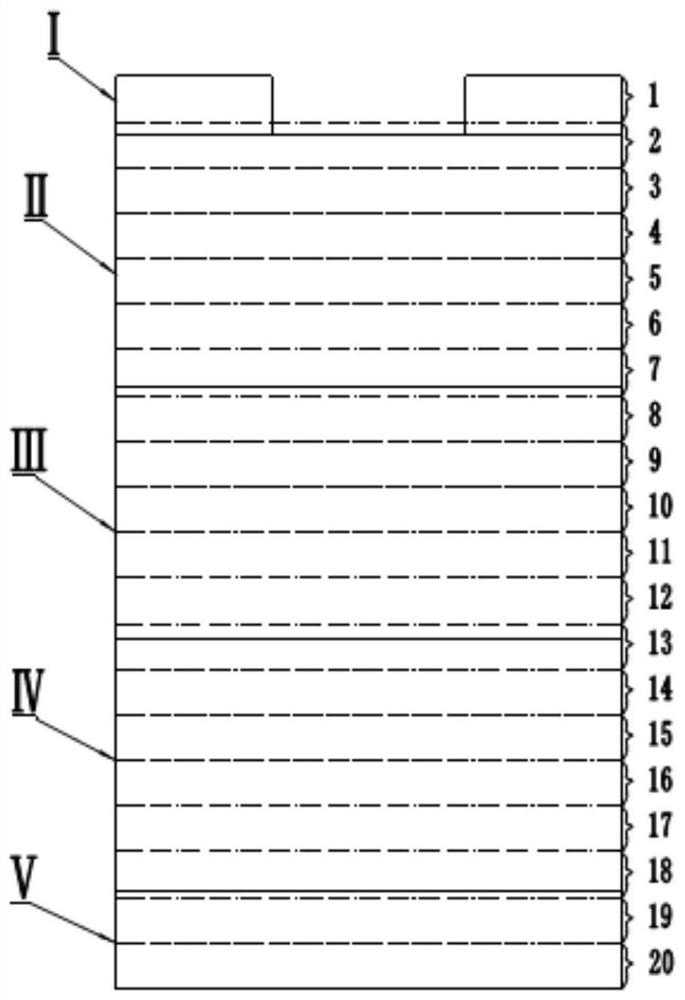

[0023] See Figure 1, figure 2 , the specific embodiment of the present invention is: the blank to be cut that it aims at comprises guide strip I, quartz crystal material and backing plate V, wherein the quartz crystal material is made of the first quartz crystal material II and the second quartz crystal material that are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com