A kind of method for extracting tannin from tang pear

A technology of tannic acid and Tangli, which is applied in the field of tannic acid extraction, can solve the problems of complex tannic acid extraction process and low extraction purity, and achieve the effect of simple extraction means and good operation reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

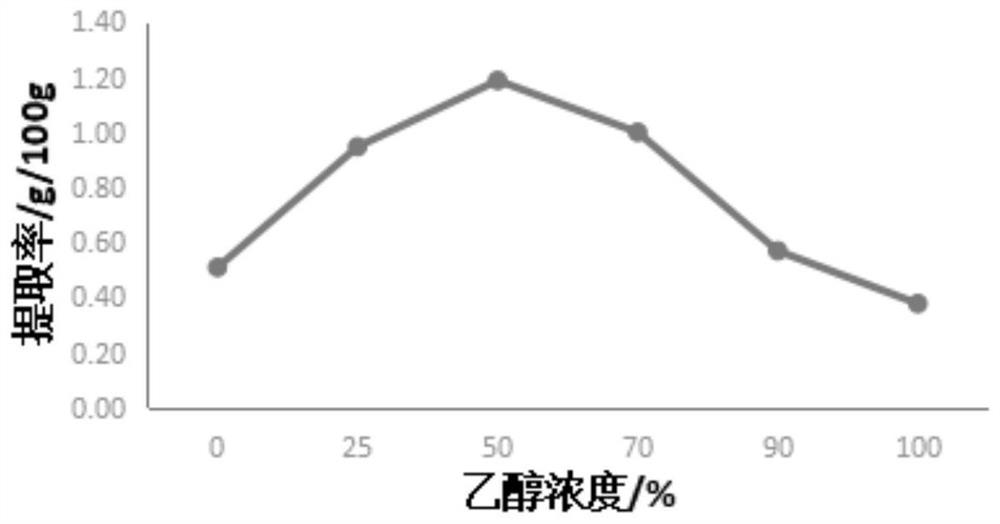

[0038] Weigh 6 parts of about 1.67g of Tangli powder into 6 identical conical flasks, respectively, add 100mL of ethanol solutions of different concentrations (ethanol concentrations are 0%, 25%, 50%, 70%, 90%, 100%) ), cover with a glass slide, and perform ultrasonic extraction at 50 °C and 32 kHz for 30 min, transfer the extracted solution to a centrifuge tube, centrifuge at 4000 r / min for 5 min, and filter the supernatant to a 100 mL tube to constant volume For spare use, take 1 mL of the extract for color development to measure the absorbance, and obtain six groups of data absorbance A1, A2, A3, A4, A5, and A6, such as figure 1 shown.

[0039] Depend on figure 1 It can be seen that when the ethanol concentration is between 0-50%, the tannin extraction rate increases with the increase of the ethanol concentration. When the ethanol concentration is 50%, the tannin extraction rate is the largest, and the tannin extraction rate is 1.19%; when the ethanol concentration is gre...

Embodiment 2

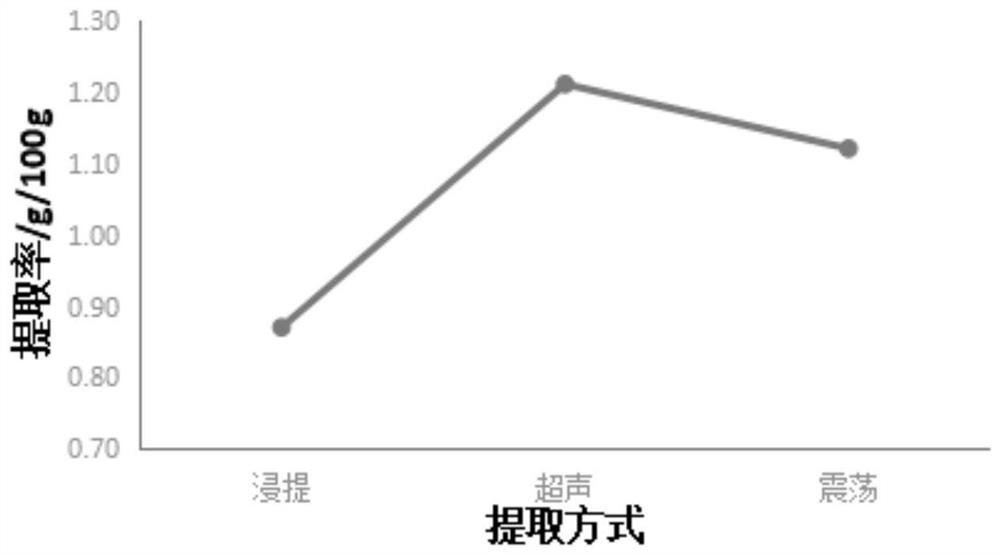

[0041] Weigh 6 parts of about 1.67g of tangli powder into 6 identical conical flasks, add 100 mL of 50% ethanol solution to each, cover with glass slides, and mark the 6 samples as 1# and 2# respectively. , 3#, 4#, 5#, 6#. 1# and 2# were placed in an electric heating constant temperature water bath set to 50°C in advance, extracted in the water bath for 30min, taken out and placed, cooled to room temperature; 3# and 4# were placed in a 50°C ultrasonic cleaner, 32kHz ultrasonic for 30min, taken out and cooled ; 5# and 6# were placed in a 50°C water bath constant temperature oscillator, shaken horizontally for 30min, and taken out. The extracted solution was transferred to a centrifuge tube, centrifuged at 4000 r / min for 5 min, and the supernatant was filtered into a 100 mL tube to constant volume for later use. Take 1 mL of the extraction solution for color development and measure the absorbance, respectively, and compare the tannin extraction rates of different extraction met...

Embodiment 3

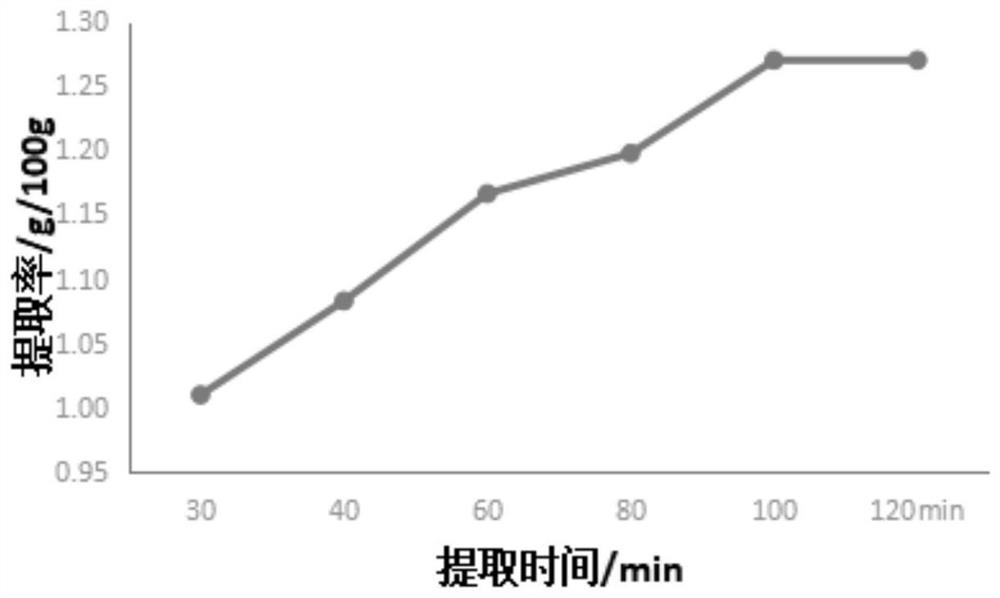

[0044] Weigh 6 parts of about 1.67g of tangli powder into 6 identical conical flasks, add 100 mL of 50% ethanol solution to each, cover with a glass slide, and perform ultrasonic extraction at 50 °C and 32 kHz at the same time. After different times, the extracted solution was transferred to a centrifuge tube, centrifuged at 4000 r / min for 5 min, and the supernatant was filtered to a 100 mL tube to constant volume for later use. Take 1 mL of the extract for color development and measure the absorbance, and compare the extraction rates of tannins with different extraction times (30min, 40min, 60min, 80min, 100min, 120min), and obtain six groups of data of C1, C2, C3, C4, C5, and C6. absorbance, as image 3 shown.

[0045] pass image 3 It can be seen that before 100min, with the increase of extraction time, the extraction rate of tannins gradually increased, mainly because the extraction time was too short and the extraction of tannins was incomplete; with the increase of ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com