IgM purification method

A purification method, the technology of ammonium sulfate method, applied in chemical instruments and methods, peptide preparation methods, organic chemistry, etc., can solve problems such as difficulties, and achieve the effects of small cross-reaction, product stability, and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1 IgM rough extraction

[0052] 1) Ammonium sulfate precipitation treatment: Dilute the centrifuged serum with PBS (pH=7.0-8.0), add saturated ammonium sulfate to a final concentration of 40%-60%, let it stand at 4 degrees for more than 30 minutes, and discard the supernatant by centrifugation ;

[0053] 2) Reconstitute the collected precipitate with a buffer solution containing more than 150 mM salt, pH = 7.0-9.0; after reconstitution, perform dialysis treatment with purified water at a ratio of 1:1000 or more for 3-5 days;

[0054] 3) Collect the precipitate after dialysis, redissolve it with a buffer solution containing more than 150mM salt, pH = 7.0-9.0, adjust the pH = 3.0-5.0 after redissolution, add n-octanoic acid at a ratio of 1ml: at least 5μl, and keep at 20°C After reacting at ~35°C for 10min~2h, centrifuge to discard the precipitate; adjust the pH of the collected supernatant to 7.0~9.0 and add saturated ammonium sulfate to a final concentration of...

Embodiment 2

[0055] Example 2 IgM rough extraction

[0056] Same as Example 1, the difference is that step 1) is replaced by: use polyethylene glycol precipitation treatment: after centrifugation and clarification of the antibody supernatant secreted by hybridoma cells cultured in serum-free medium, use an equal amount of PBS, pH=7.0 ~8.0 Dilute, add PEG6000 gradually under stirring to make the final concentration 5%, let stand for 30min, discard the supernatant after centrifugation.

Embodiment 3

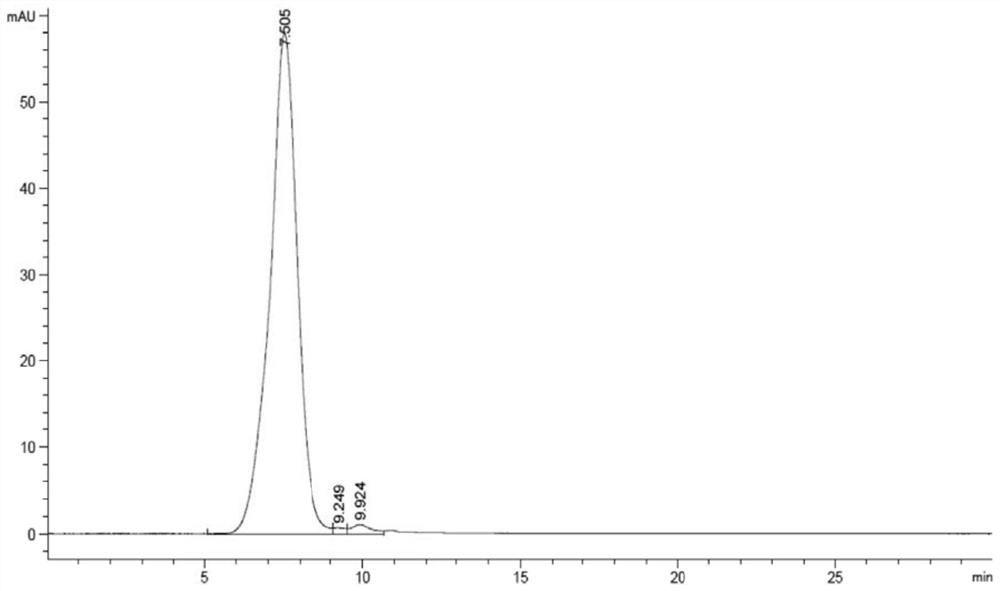

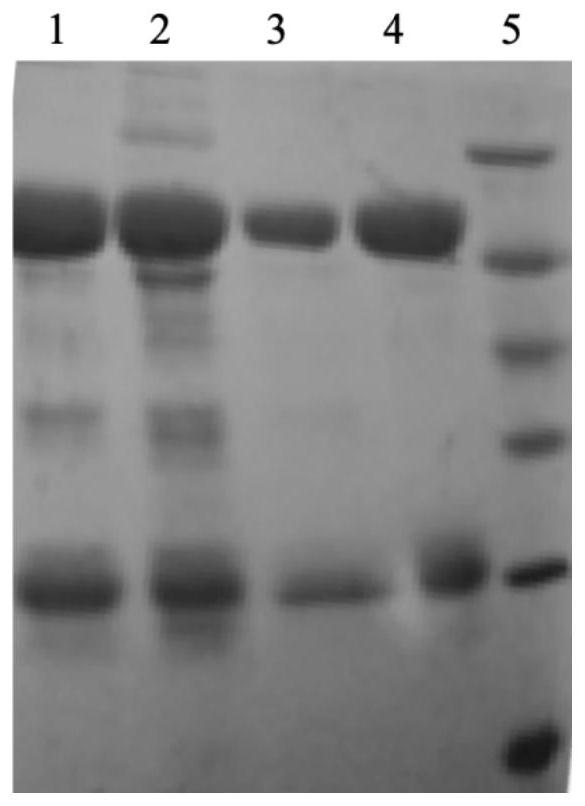

[0057] Embodiment 3 IgM refined extraction

[0058] The crude extract obtained in Example 1 is further operated:

[0059] (1) Hydrophobic chromatography:

[0060] The supernatant is passed through the hydrophobic medium of GE Company, and the hydrophobic ligand used in the present invention is phenyl.

[0061] Buffer A: 20mM PB+1000mM NaCl, pH=8.0;

[0062] Load the sample after equilibrating the column with Buffer A, and collect the breakthrough sample when the UV absorbance value starts to rise.

[0063] (2) CHT column

[0064] The above breakthrough samples were purified by Bio-Rad's CHT II medium

[0065] Buffer A: 15mM PB+1000mM NaCl, pH=8.0;

[0066] Buffer B: 300mM PB, pH=8.0;

[0067] Load the sample after equilibrating the column with Buffer A, elute with a linear gradient of 0% to 100% Buffer B, and collect the eluted samples.

[0068] (3) G column purification

[0069] The eluted sample was purified by GE's Protein G column

[0070] Buffer A: 30mM PB+1000mM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com