Anti-aging nylon modified elastomer and preparation method thereof

An anti-aging and elastomer technology, applied in the field of anti-aging nylon modified elastomer and its preparation, can solve the problems of poor impact performance, lack of high elasticity of elastomer, weak anti-aging ability, etc., to improve the performance of anti-ultraviolet aging , The effect of nylon elastomer interior fluffy, good deformation recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

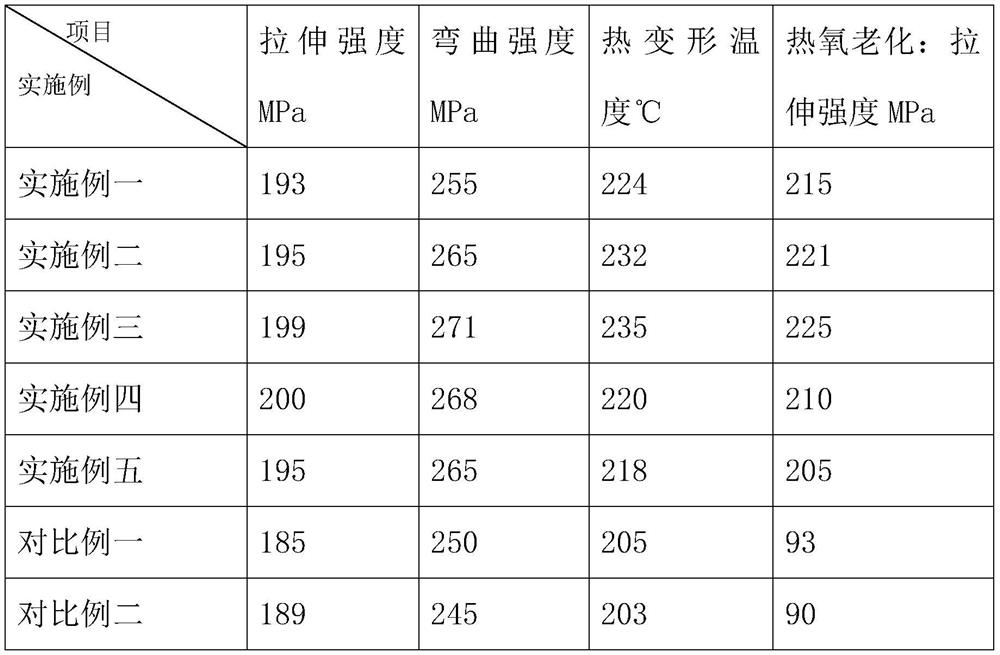

Examples

Embodiment 1

[0025] A kind of anti-aging nylon modified elastomer that the present invention proposes, is made up of the raw material of following weight part: nylon 6 60 parts, chlorinated butyl rubber 6 parts, 5.5 parts of pine sylvestris lignocellulose, 3.5 parts of flame retardant, 35 parts of naphthenic oil, 30 parts of maleic anhydride grafted polypropylene, 6 parts of graphene, 1.5 parts of o-hydroxybenzophenone derivatives, 1.5 parts of ethylene, 1.3 parts of 2,6-di-tert-butyl-p-cresol , 1.3 parts of antioxidant 1010, 1.3 parts of triethylenediamine, and 1.0 parts of 2,5-furandione.

[0026] A kind of preparation method of aging-resistant nylon modified elastomer that the present invention proposes, comprises the following steps,

[0027] S1, carrying out the polyaddition reaction of the above weight parts of ethylene to form polyethylene, fully mixing the polyethylene and o-hydroxybenzophenone derivatives uniformly to obtain a mixture A;

[0028] S2, mixing the nylon 6, chlorobut...

Embodiment 2

[0033] A kind of anti-aging nylon modified elastomer that the present invention proposes, is made up of the raw material of following parts by weight: nylon 6 78 parts, chlorinated butyl rubber 12 parts, pine sylvestris lignocellulose 7 parts, flame retardant 4.0 parts, 42 parts of naphthenic oil, 33 parts of maleic anhydride grafted polypropylene, 6.2 parts of graphene, 1.6 parts of o-hydroxybenzophenone derivatives, 1.6 parts of ethylene, 1.5 parts of 2,6-di-tert-butyl-p-cresol , 1.5 parts of antioxidant 1010, 1.5 parts of triethylenediamine, and 1.2 parts of 2,5-furandione.

[0034] A kind of preparation method of aging-resistant nylon modified elastomer that the present invention proposes, comprises the following steps,

[0035] S1, carrying out the polyaddition reaction of the above weight parts of ethylene to form polyethylene, fully mixing the polyethylene and o-hydroxybenzophenone derivatives uniformly to obtain a mixture A;

[0036] S2, mixing the nylon 6, chlorobuty...

Embodiment 3

[0041] An anti-aging nylon modified elastomer proposed by the present invention is composed of the following raw materials in parts by weight: 652.5 parts of nylon, 52.5 parts of nylon 66, 20 parts of chlorinated butyl rubber, 15 parts of pine wood cellulose, flame retardant 6 parts of agent, 50 parts of naphthenic oil, 40 parts of maleic anhydride grafted polypropylene, 6.5 parts of graphene, 1.8 parts of o-hydroxybenzophenone derivatives, 1.8 parts of ethylene, 2,6-di-tert-butyl p- 1.7 parts of cresol, 1.7 parts of antioxidant 1010, 1.7 parts of triethylenediamine, and 1.5 parts of 2,5-furandione.

[0042] A kind of preparation method of aging-resistant nylon modified elastomer that the present invention proposes, comprises the following steps,

[0043] S1, carrying out the polyaddition reaction of the above weight parts of ethylene to form polyethylene, fully mixing the polyethylene and o-hydroxybenzophenone derivatives uniformly to obtain a mixture A;

[0044] S2, mixing ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap