Water-soluble fluorescent whitening agent and preparation method thereof

A fluorescent whitening agent and water-soluble technology, which is applied in the field of fluorescent whitening agents, can solve the problems of unstable storage and poor water solubility of fluorescent whitening agents, and achieve the effect of high solubility and good system stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0013] The first aspect of the present invention provides a kind of preparation method of water-soluble fluorescent whitening agent, comprises the steps:

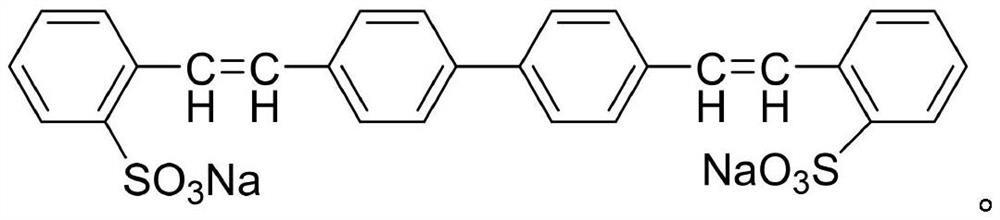

[0014] S1: After mixing the distyrene biphenyl type fluorescent whitening agent dye, sodium alkylbenzene sulfonate, fatty alcohol polyoxyethylene ether and polyethylene glycol, grind until the particle size is ≦20 μm to obtain the first mixture;

[0015] S2: Add polyhydric alcohol to the above first mixture, and obtain the second mixture after fully dissolving;

[0016] S3: Add deionized water to the above second mixture, and mix uniformly to obtain a water-soluble fluorescent whitening agent.

[0017] The method of the invention can stably disperse the distyryl biphenyl type fluorescent whitening agent dye in the deionized water, and the distyryl biphenyl type fluorescent whitening agent dye in the formed system has high solubility and good system stability.

[0018] In the above step S1, the fineness of the first mixture...

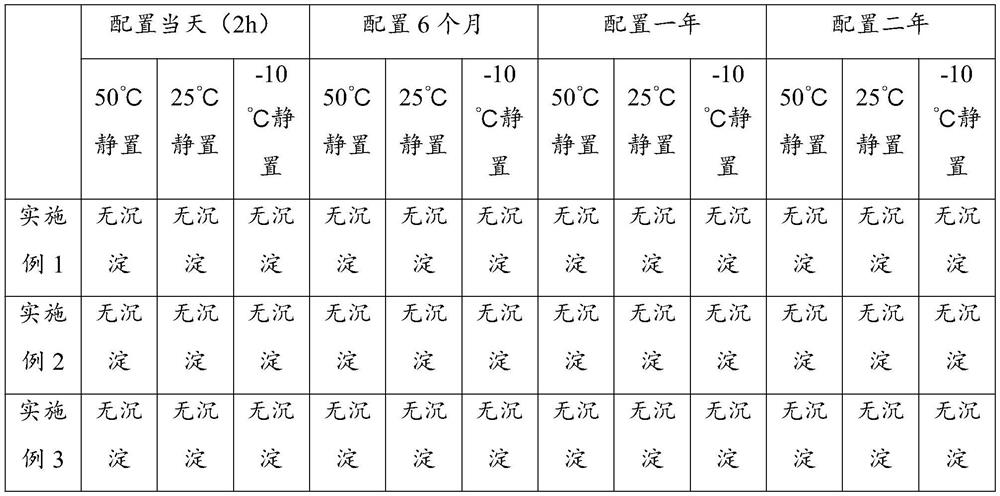

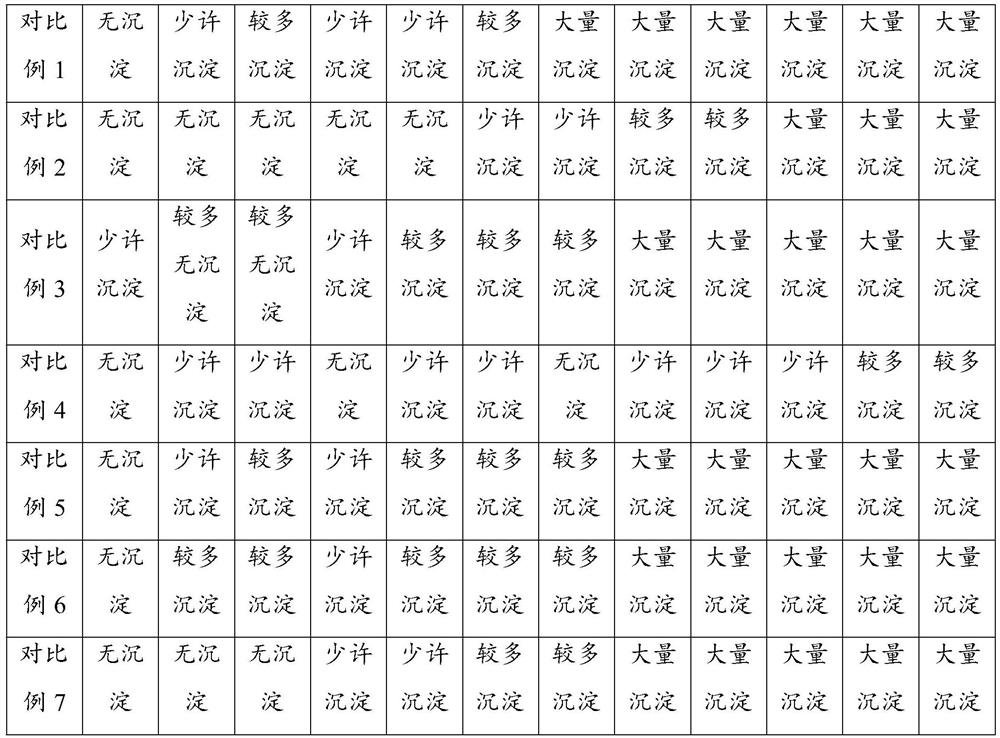

Embodiment 1

[0028] (1) After mixing stilbene biphenyl type fluorescent whitening agent dye, sodium cetylbenzenesulfonate, AEO-9 and PEG-2000, grind until the particle size is ≦20 μm to obtain the first mixture;

[0029] (2) Add ethylene glycol to the above-mentioned first mixture, after ultrasonic dissolution, obtain the second mixture;

[0030] (3) Adding deionized water to the above second mixture, and ultrasonically dispersing to obtain a water-soluble fluorescent whitening agent.

[0031] In this example, stilbene biphenyl type fluorescent whitening agent dye: sodium hexadecylbenzene sulfonate: AEO-9: PEG-2000: ethylene glycol: deionized water = 1: 0.08: 0.3: 0.25: 0.3:0.6.

Embodiment 2

[0033] (1) After mixing the stilbene biphenyl type fluorescent whitening agent dye, sodium hexadecylbenzene sulfonate, AEO-9 and PEG-1000, grind until the particle size is ≦20 μm to obtain the first mixture;

[0034] (2) Add propylene glycol to the first mixture, and after ultrasonic dissolution, obtain the second mixture;

[0035] (3) Adding deionized water to the above second mixture, and ultrasonically dispersing to obtain a water-soluble fluorescent whitening agent.

[0036] In this example, stilbene biphenyl type fluorescent whitening agent dye: sodium hexadecylbenzene sulfonate: AEO-9: PEG-1000: propylene glycol: deionized water = 1: 0.05: 0.25: 0.3: 0.4: 0.7.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap