A kind of low temperature integrated clean fracturing fluid and preparation method thereof

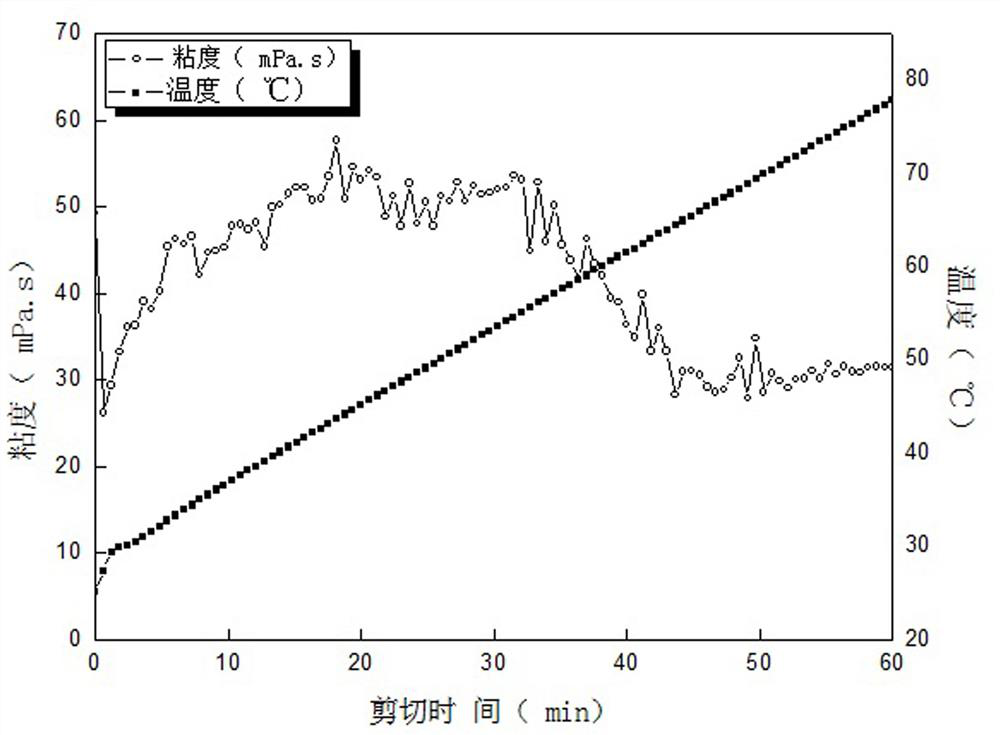

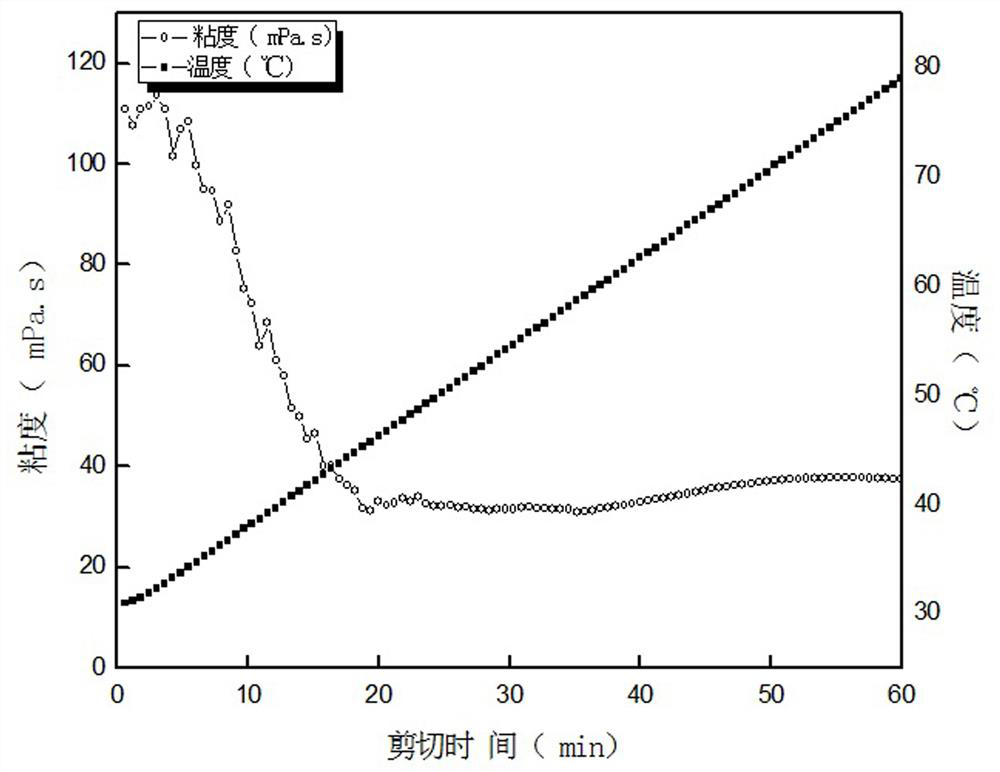

A clean fracturing fluid and low-temperature technology, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as increasing construction risks, increasing fracturing construction costs, and failing to meet the needs of fracturing reconstruction, achieving Wide temperature range, strong temperature resistance, good sand carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. A low-temperature integrated clean fracturing fluid, according to the mass percentage of 100%, is composed of the following components:

[0025] Low temperature thickener: behenyl propylamine oxide 0.5%,

[0026] Elasticity enhancer: potassium chloride 1%,

[0027] Gel breaker: ammonium persulfate 0.1%,

[0028] Gel breaking initiator: sodium thiosulfate 0.1%,

[0029] The remainder is water.

[0030] 2. The preparation method of the low-temperature integrated clean fracturing fluid, comprising the following steps:

[0031] (1) Add low-temperature thickener and elasticity promoter into water, and stir for 3 minutes to obtain the original glue;

[0032] (2) In a stirring state, add a gel breaking agent and a gel breaking initiator to the raw glue solution, and stir to obtain the fracturing fluid.

Embodiment 2

[0034] 1. A low-temperature integrated clean fracturing fluid, according to the mass percentage of 100%, is composed of the following components:

[0035] Low temperature thickener: behenyl propyl amine oxide 2%,

[0036] Elasticity enhancer: potassium chloride 0.5%,

[0037] Gel breaker: ammonium persulfate 0.1%,

[0038] Gel breaking initiator: sodium thiosulfate 0.1%,

[0039] The remainder is water.

[0040] 2. The preparation method of the low-temperature integrated clean fracturing fluid, comprising the following steps:

[0041] (1) Add low-temperature thickener and elasticity promoter into water, and stir for 1 min to obtain the original glue;

[0042] (2) In a stirring state, add a gel breaking agent and a gel breaking initiator to the raw glue solution, and stir to obtain the fracturing fluid.

Embodiment 3

[0044] 1. A low-temperature integrated clean fracturing fluid, according to the mass percentage of 100%, is composed of the following components:

[0045] Low temperature thickener: a mixture of equal quality behenamidopropyl isosulbetaine and behenylpropylamine oxide: 3%;

[0046] Elasticity promoter: a mixture of equal mass of potassium chloride, sodium chloride and ammonium chloride: 2%;

[0047] Gel breaker: ammonium persulfate 0.5%;

[0048] Gel breaking initiator: sodium thiosulfate 0.2%;

[0049] The remainder is water.

[0050] 2. The preparation method of the low-temperature integrated clean fracturing fluid, comprising the following steps:

[0051] (1) Add low-temperature thickener and elasticity enhancer into water, and stir for 2 minutes to obtain the original glue;

[0052] (2) In a stirring state, add a gel breaking agent and a gel breaking initiator to the raw glue solution, and stir to obtain the fracturing fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com