Special steel STDB1570 for bumper bar of side door of passenger vehicle and manufacturing method of special steel

A manufacturing method and anti-collision bar technology, applied in the direction of temperature control, etc., can solve problems such as unstable hardness and poor surface quality, and achieve the effect of ensuring the stability of belt threading, the quality stability of finished products, and the optimization of rolling load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

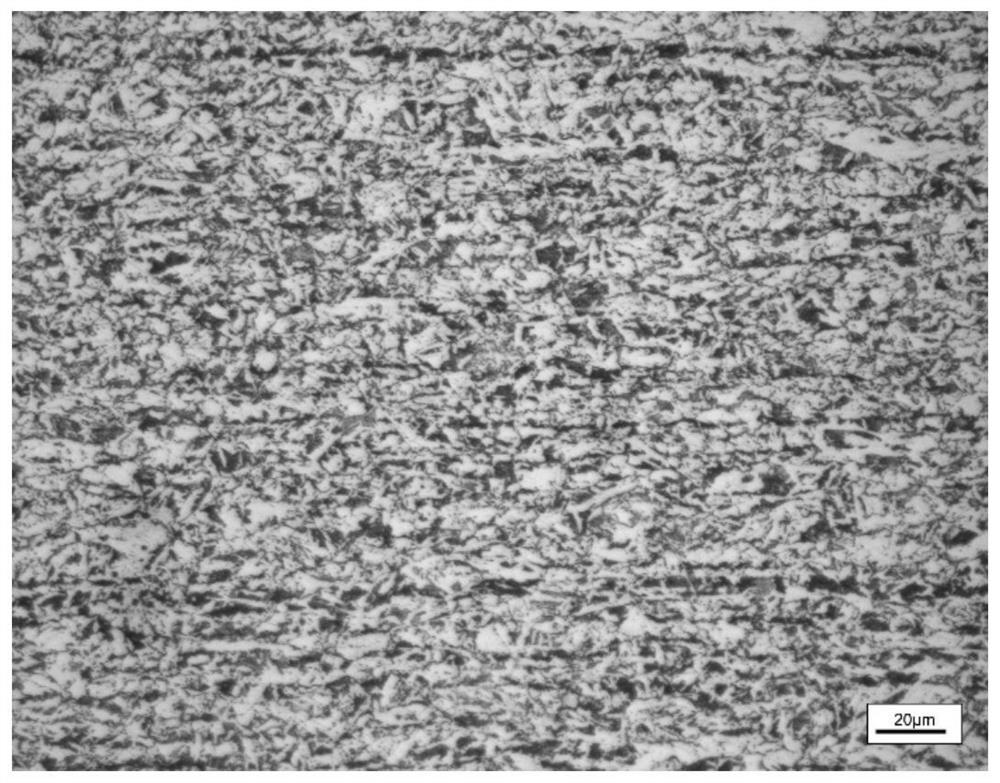

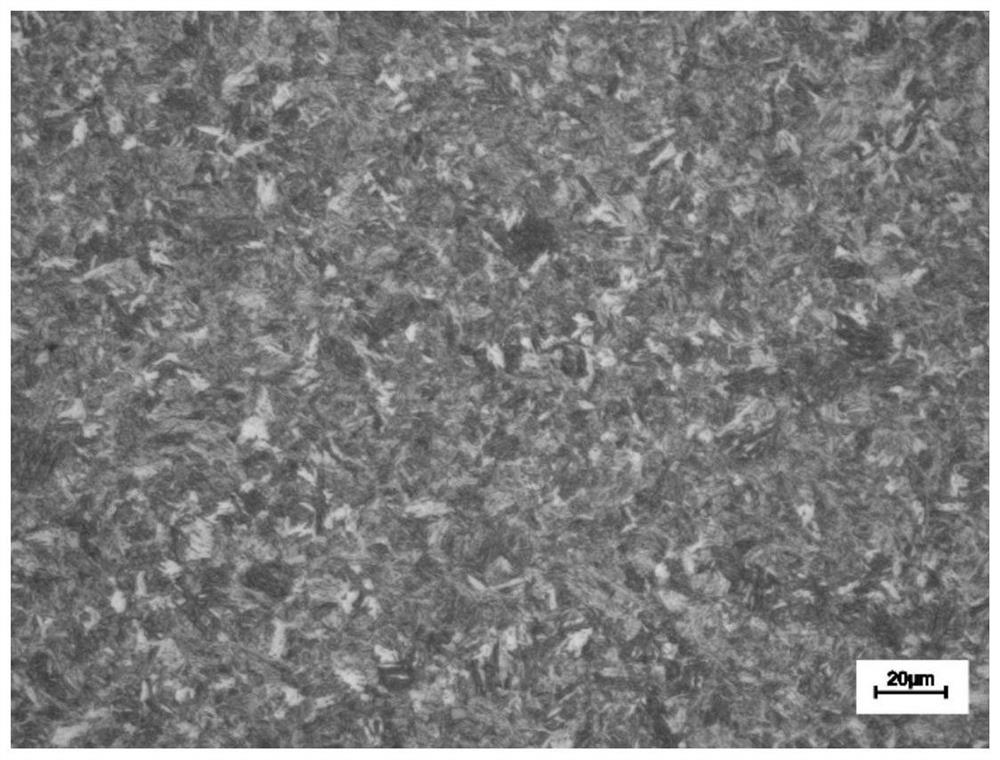

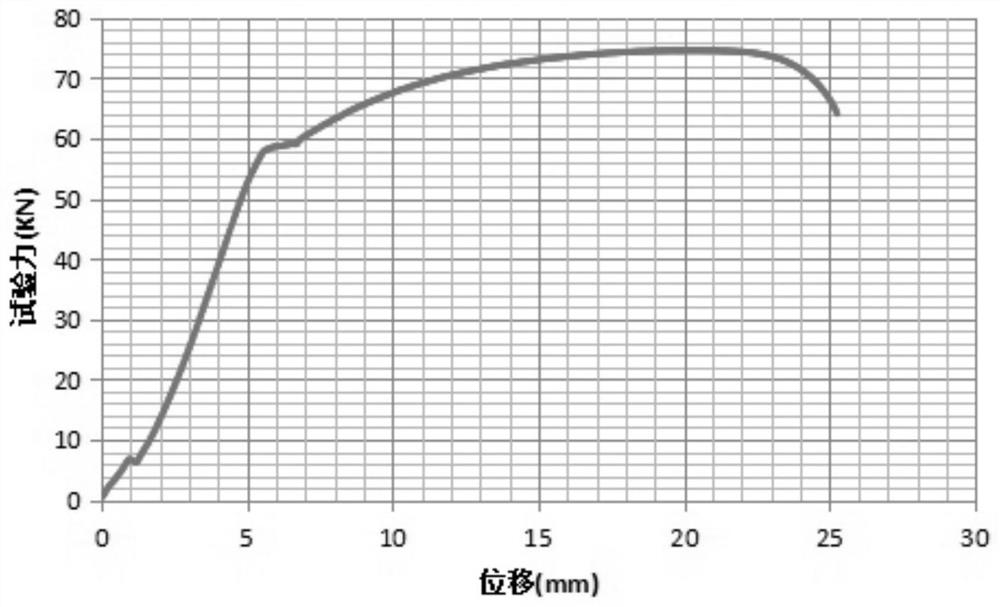

Image

Examples

Embodiment 1

[0046] The special steel STDB1570 for the side door anti-collision bar of the passenger car described in this embodiment contains the following components and weight percentages: C 0.24%, Si 0.25%, Mn 1.32%, P 0.014%, S 0.001%, Cr 0.20%, B 0.003%, N0.0034%, Ti 0.032%; the rest are Fe and unavoidable impurities. The composition design is shown in Table 1.

[0047] The manufacturing method of the special steel STDB1570 comprises steelmaking process, continuous casting and 2150mm steel rolling production (relevant parameters are shown in Table 2), specifically:

[0048] (1) Steelmaking process:

[0049] ①Using lime and granular magnesium pre-composite desulfurization, the S content of the outbound station is ≯0.001%, and the temperature of the molten iron is 1354°C;

[0050] ②Converter end point temperature 1661℃, P≯0.010%;

[0051] ③ Refining exit temperature is 1565°C, white slag is produced, alloy is fine-tuned, B and Ti are adjusted before soft blowing, micro-positive pres...

Embodiment 2

[0061] The special steel STDB1570 for the side door anti-collision bar of the passenger car described in this embodiment contains the following components and weight percentages: C 0.23%, Si 0.25%, Mn 1.27%, P 0.014%, S 0.001%, Cr 0.20%, B 0.003%, N0.0030%, Ti 0.030%, and the rest are Fe and unavoidable impurities. The composition design is shown in Table 1.

[0062] The manufacturing method of the special steel STDB1570 includes steelmaking process, continuous casting and 2150mm steel rolling production, specifically:

[0063] (1) Steelmaking process:

[0064] ① Deep desulfurization of molten iron, requiring S content ≯0.001% at the exit of the station, and molten iron temperature 1321°C;

[0065] ②Converter end point temperature 1673℃, P≯0.010%;

[0066] ③ Refining exit temperature is 1563℃, white slag is produced, alloy is fine-tuned, B and Ti are adjusted before soft blowing, micro-positive pressure operation is carried out throughout the refining process, the effect of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap