Production process of wormwood fiber and wool fiber blended yarn

A technology of wormwood fiber and wool fiber, which is applied in the directions of spinning machine, fiber cleaning, fiber processing, etc., can solve the problem of no improvement in strength, and achieve the effect of ensuring the grinding effect, increasing humidity and improving strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

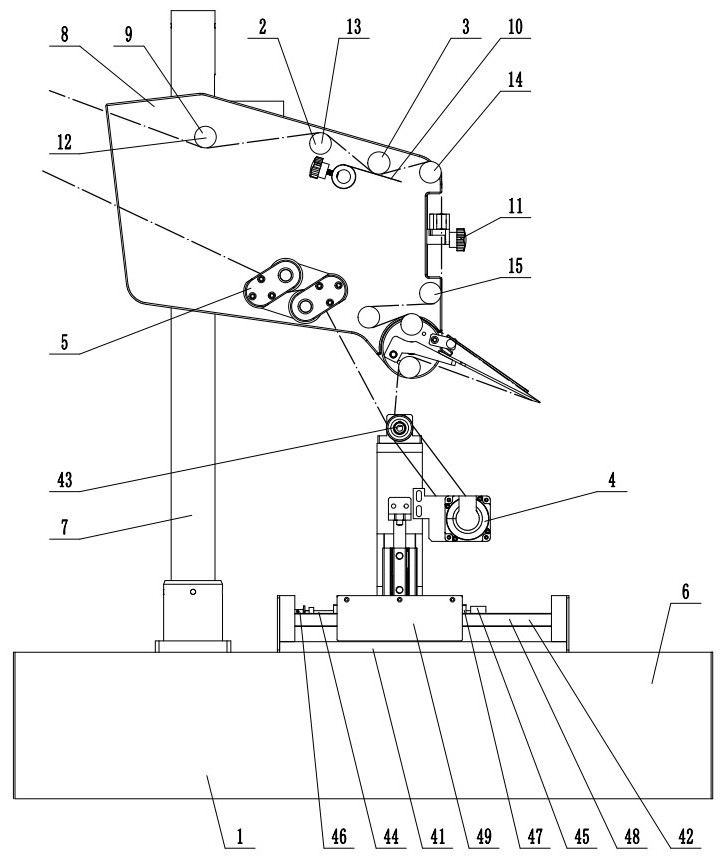

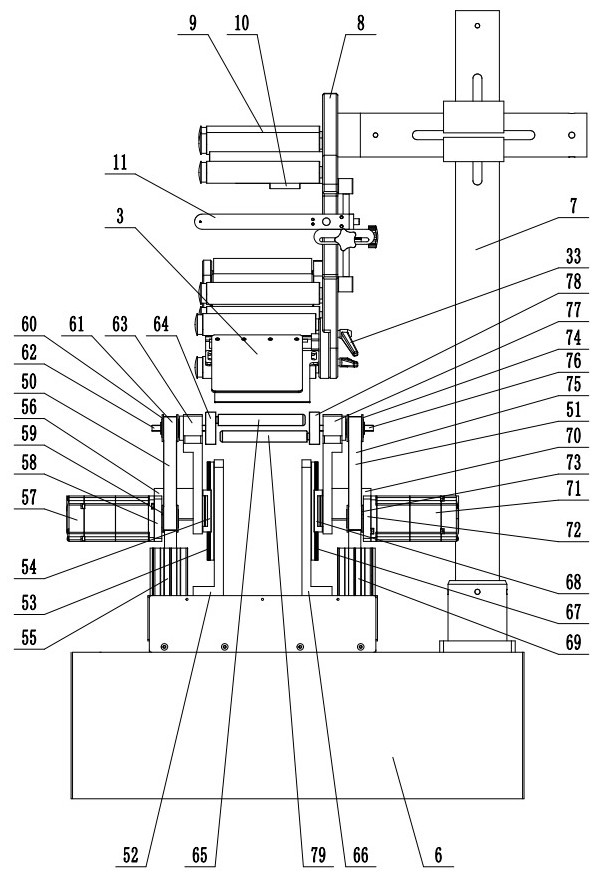

[0037]The present invention will be further described in detail below with reference to the drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

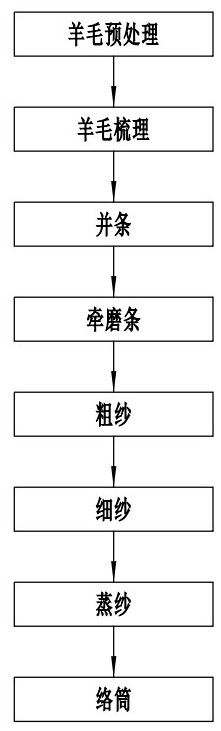

[0038]Such asfigure 1 As shown, a production process of wormwood fiber and wool fiber blended yarn includes the following steps:

[0039]Step 1: Wool pretreatment, open the wool, add blending oil and antistatic agent to the wool, by weight percentage, 95 parts of wool, 4 parts of crude oil, 1 part of antistatic agent, after adding oil The moisture regain rate of wool is 21.7%, and the wool is stored for 24 hours after oiling;

[0040]Step 2: Wool carding, the pretreated wool is carded and removed in the carding machine;

[0041]Step 3: Draw, draw the carded wool and wormwood fiber with a draw frame to form a blended sliver;

[0042]Step 4: Drag and grind the sliver, and process the blended sliver formed after drawing with special traction and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com