Warm-keeping antibacterial knitted underwear fabric and preparation method thereof

A technology of underwear fabrics and antibacterial agents, applied in underwear, knitting, baby underwear, etc., can solve problems such as chapped, skin allergies, and roughness, and achieve the effects of reducing the growth of bacteria and mold, enhancing heat preservation, and large friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

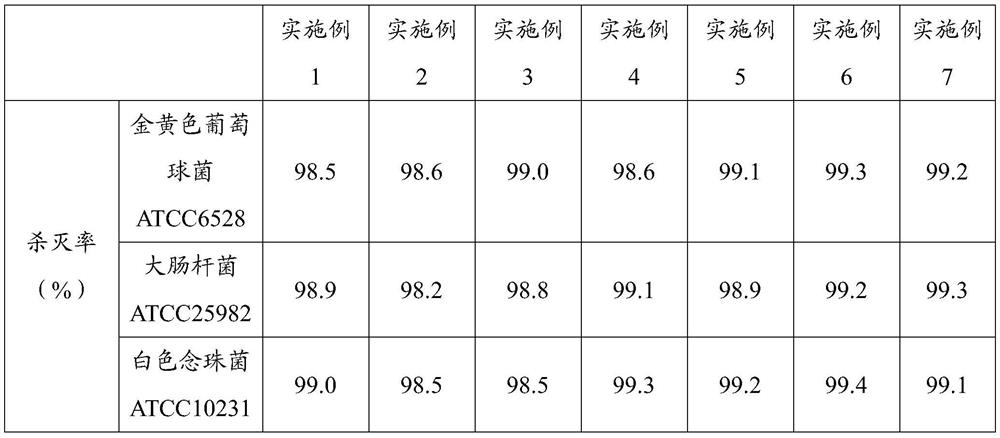

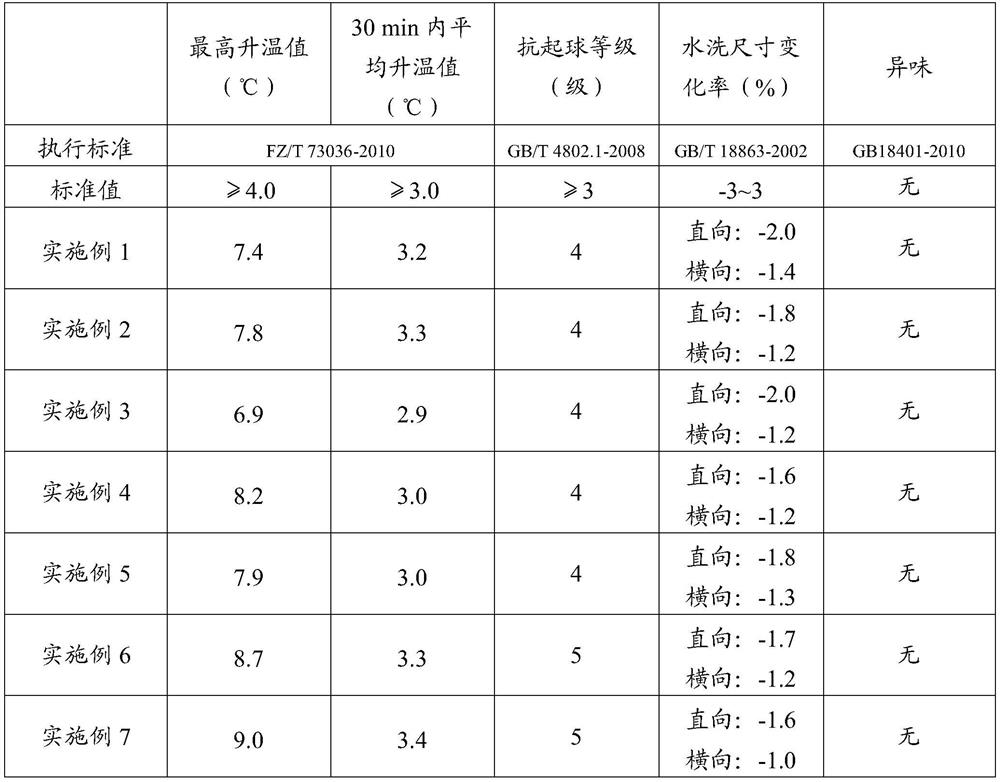

Examples

Embodiment 1

[0028] A kind of preparation method of warm antibacterial knitted underwear fabric, described method comprises steps as follows:

[0029] Bulk yarn preparation: take high-shrinkage acrylic fibers and cotton fibers with a count of 60S and blend them at a blending ratio of 1:1 to obtain raw yarns, and then obtain the bulked yarns through heat and humidity treatment, and the bulking degree is 30%; the high The fiber fineness of shrinkable acrylic fiber is 2.4dtex, and the shrinkage rate in boiling water is 40%.

[0030] Preparation of antibacterial yarn: Mix modal fiber solution and antibacterial agent evenly, and obtain antibacterial yarn with a fineness of 30D through wet spinning. The antibacterial agent is commercially available silver ion antibacterial agent Silvadur ET, and the antibacterial agent accounts for the 1.0wt.% of the weight of the modal fiber; the spinneret hole of the wet spinning is trilobal.

[0031] Fabric preparation: by mass fraction, the surface fabric i...

Embodiment 2

[0034] A kind of preparation method of warm antibacterial knitted underwear fabric, described method comprises steps as follows:

[0035] Bulk yarn preparation: take high-shrinkage acrylic fibers and cotton fibers with a count of 60S and blend them at a blending ratio of 0.66:1 to obtain raw yarns, and then obtain the bulked yarns through wet heat treatment, and the bulking degree is 33%; the high The fiber fineness of shrinkable acrylic fiber is 2.0dtex, and the shrinkage rate in boiling water is 45%.

[0036] Preparation of antibacterial yarn: mixing bamboo fiber solution and antibacterial agent uniformly, and obtaining the antibacterial yarn with fineness of 25D through wet spinning, the antibacterial agent is commercially available silver ion antibacterial agent Silvadur ET, and the antibacterial agent accounts for the 1.2wt.% of the bamboo fiber weight; the spinneret holes of the wet spinning are trilobal.

[0037] Fabric preparation: by mass fraction, the surface fabric...

Embodiment 3

[0040] A kind of preparation method of warm antibacterial knitted underwear fabric, described method comprises steps as follows:

[0041] Bulk yarn preparation: take high-shrinkage acrylic fibers and cotton fibers with a count of 50S and blend them at a blending ratio of 1.2:1 to obtain raw yarns, and then obtain the bulky yarns through wet heat treatment, and the bulkiness is 35%; the high The fiber fineness of shrinkable acrylic fiber is 2.0dtex, and the shrinkage rate in boiling water is 55%.

[0042] Preparation of antibacterial yarn: mix the tencel fiber solution and antibacterial agent evenly, and obtain an antibacterial yarn with a fineness of 20D through wet spinning. The antibacterial agent is a commercially available silver ion antibacterial agent Silvadur ET, and the antibacterial agent accounts for 1.2 wt.% of the weight of the tencel fiber; the spinneret hole of the wet spinning is trilobal.

[0043] Fabric preparation: by mass fraction, the surface fabric includ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com