Pre-forming device for textile semi-finished product

A technology of preforming and semi-finished products, applied in the textile field, can solve the problems of easy shrinkage of fabrics, and achieve the effects of reducing shrinkage, reducing shrinkage, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

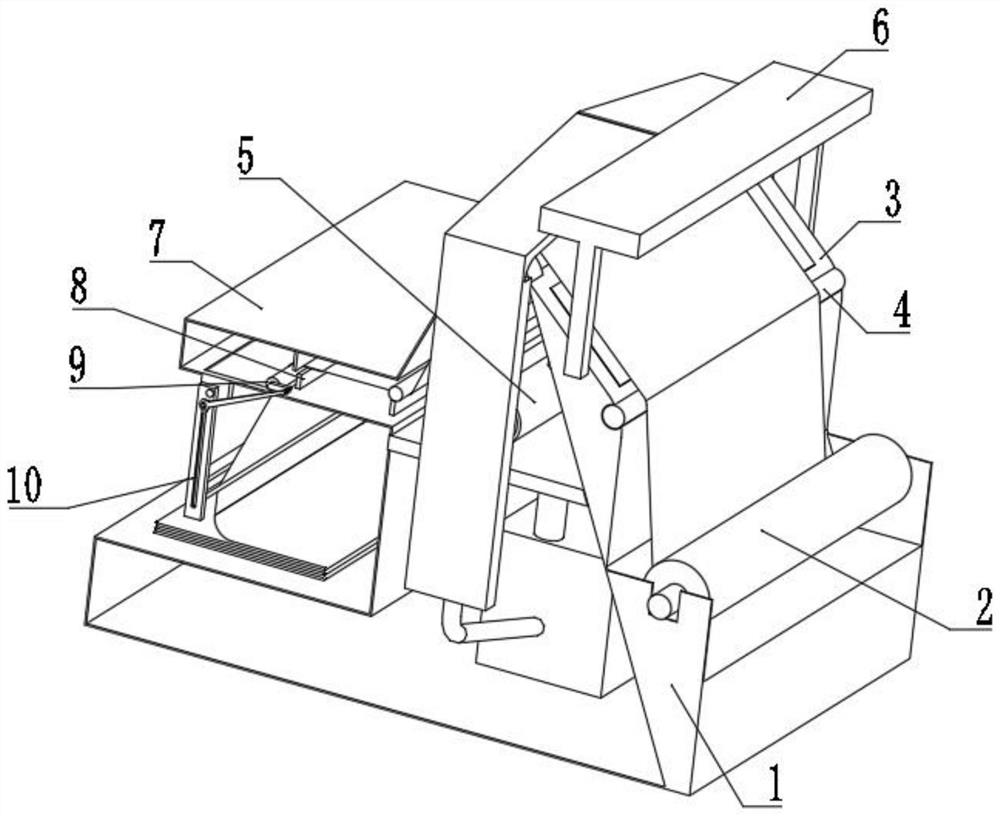

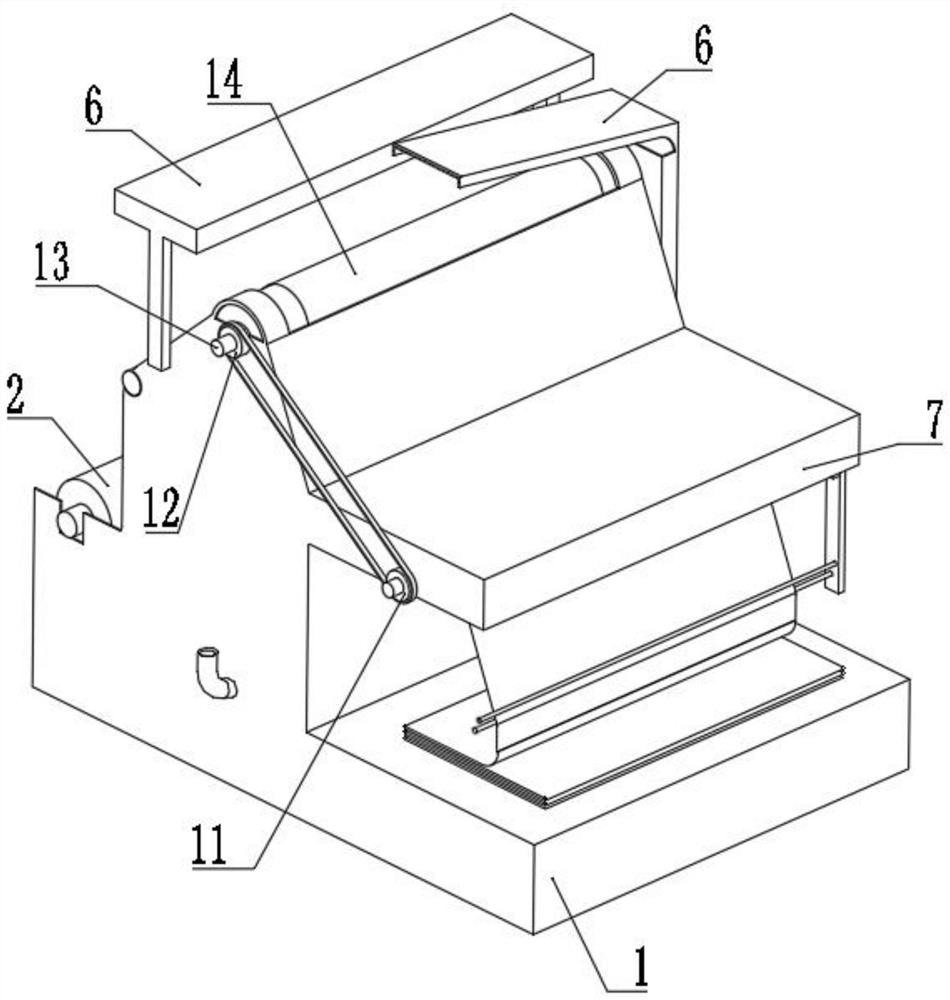

[0030] see Figure 1-6 , a preforming device for textile semi-finished products, including a device box 1, a material roller 2 is clamped on the surface of the device box 1, a detection plate 3 is fixedly installed on the surface of the device box 1, the detection plate 3 is located above the material roller 2, and the device box The two sides of 1 are fixedly connected with fixed frame 6, and the inside of device box 1 is provided with steaming and ironing mechanism 5, and the left side of device box 1 is welded with drying box 7, and the inner wall of drying box 7 is welded with clapboard 8, and drying The inner wall of case 7 is rotatably connected with turning roller 9 , the surface of turning roller 9 is provided with swing mechanism 10 , the inner wall of device case 1 is rotatably connected with driving roller 14 , and the surface of detection plate 3 is rotatably connected with transmission roller 4 .

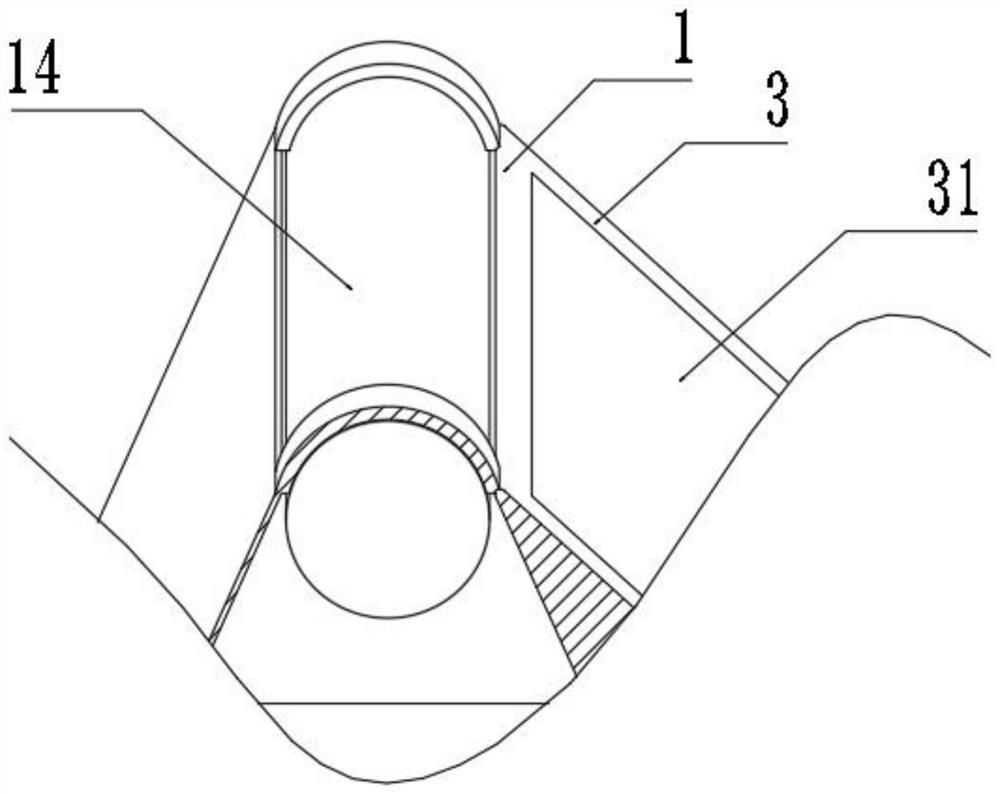

[0031] In this embodiment, two light tubes 1 31 are clamped inside...

Embodiment 2

[0037] see Figure 7, the swing mechanism 10 includes a swing shaft 101, the front portion of the swing shaft 101 is rotatably connected to a connecting rod 102, the inside of the connecting rod 102 is rotatably connected to a rotating rod 103, and the bottom of the drying box 7 is rotatably connected to a swing plate 104, which swings Two swing rods 105 are welded on the rear of the plate 104, and the rotation of the swing shaft 101 will drive the connecting rod 102 to move, thereby pushing the swing plate 104 to perform left and right swing operations, so that the cloth can be automatically flattened and folded Effect.

[0038] Further, the inside of the swing plate 104 is slidably connected to the limit plate 106, the front portion of the limit plate 106 is fixedly connected to the rear portion of the rotating rod 103, the surface of the rotating rod 103 is threaded with a nut 107, and the rear of the swing shaft 101 The part is fixedly connected to the front part of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com