Combined heat and power generation gas generator optimization system and method

A gas-fired generator and cogeneration technology, which can be used in heating systems, steam generation methods using heat carriers, gas turbine devices, etc., and can solve problems such as low efficiency and large changes in electrical load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

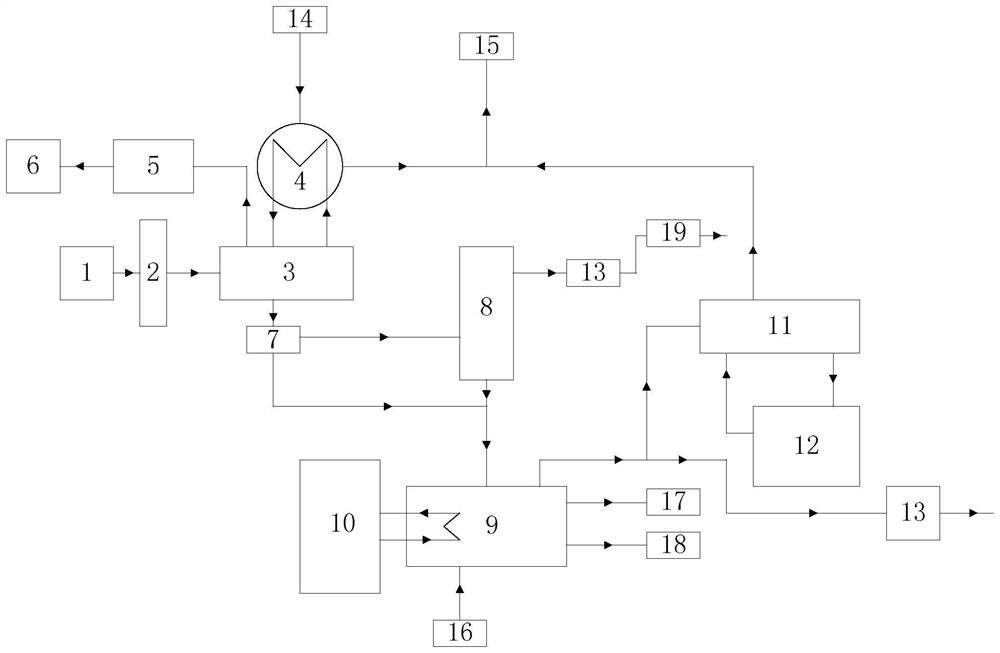

[0036] Such as figure 1 as shown,

[0037]One of the objectives of the present invention: an optimization system for cogeneration gas generators, including gas internal combustion engines 3, generators 5, waste heat boilers 8, absorption cold and warm water units 9, cooling towers 10, plate heat exchangers 11 and water storage tanks 12 , the fuel gas source 1 is connected to the gas internal combustion engine 3 through the gas source purification device 2, the gas internal combustion engine 3 is driven by the fuel gas source 1 to generate power to drive the generator 5 to generate electricity and send it to the electricity user 6, and the gas internal combustion engine 3 passes through the cylinder liner The water inlet pipe and the jacket water outlet pipe are respectively connected to the jacket water heat exchanger 4, the normal temperature water pipe 14 is connected to the water inlet of the jacket water heat exchanger 4, and the high temperature water of the jacket water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com