Reverse phase transfer extraction detection process and application of capsaicin compounds in grease

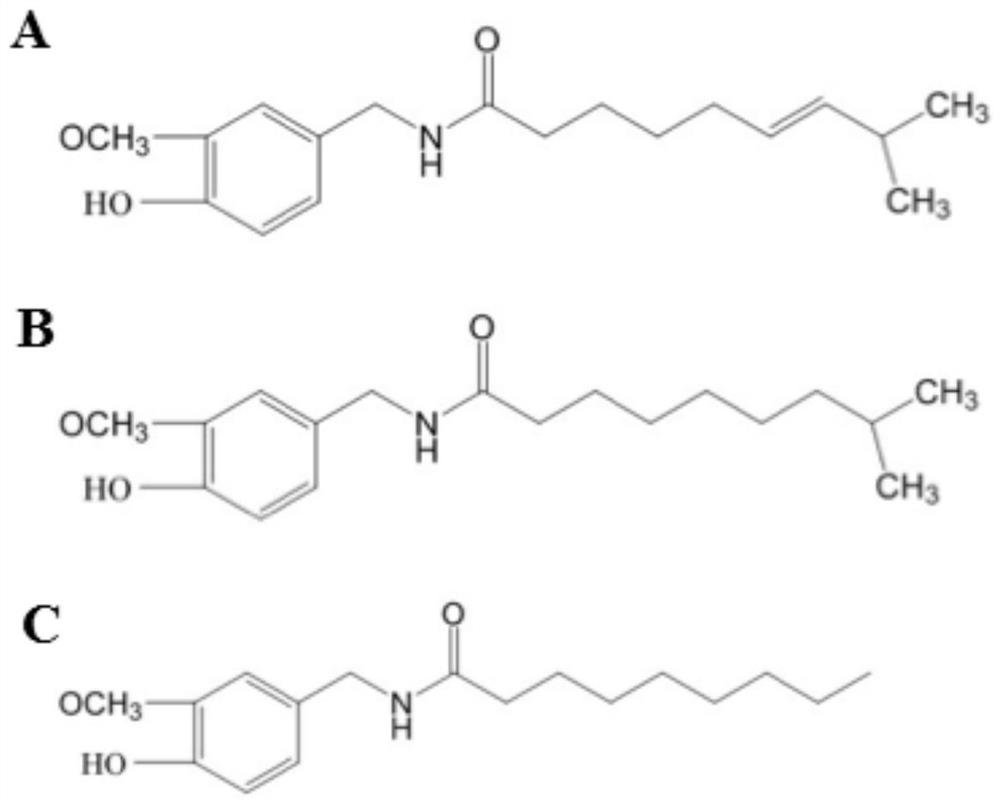

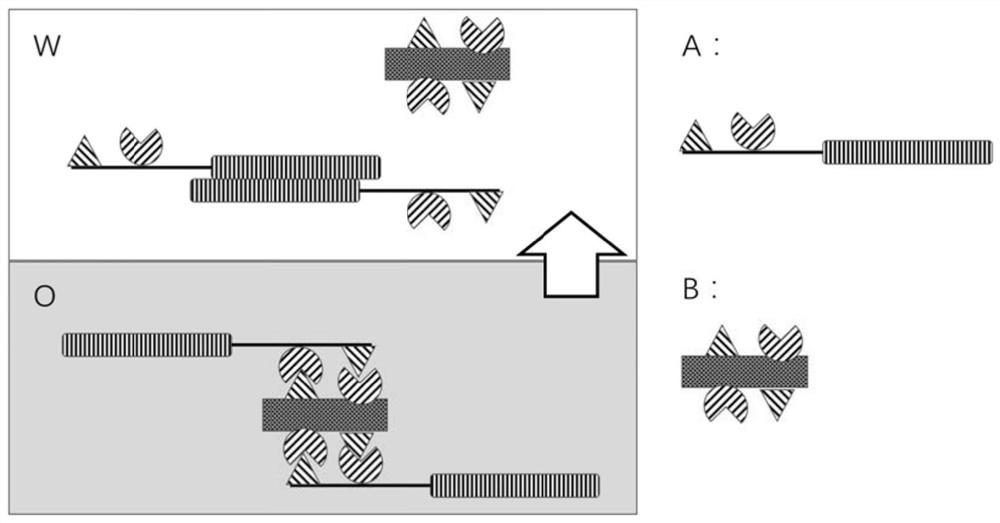

The technology of a compound, capsaicin, is applied in reverse phase transfer extraction detection process and application field, which can solve the problems of toxicity, complicated processing process and long time consumption, and achieve the effect of short detection time, simple process operation and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Add 0.2g of AEO3 reagent to 100mL of deionized water to fully dissolve it to prepare 0.2% reverse phase transfer extraction reagent.

[0045] 2) Take 0.5ml of the oil sample to be tested, and mix the oil sample with 0.2% AEO3 solution according to the volume ratio of oil sample: 0.2% AEO3 = 1:4.

[0046] 3) Shake for about 1 minute after mixing, so that the oil sample and the extraction reagent are fully mixed evenly;

[0047] 4) Immediately take 100 μL of the oil-water mixture and drop it on the sample hole of the capsaicin colloidal gold immunochromatography test card, and react for 5 minutes;

[0048] 5) Put the test card into the colloidal gold card reader, read the T line and C line gray value with the handheld test card reader, and calculate the capsaicin content in the sample from the capsaicin quantitative detection curve built in the tester. concentration.

[0049] 6) The linear detection range of the method for capsaicin in vegetable oil is 12.5-500 μg / Kg...

Embodiment 2

[0052] 1) Take 1 g of APE5 reagent, add 100 mL of phosphate buffer (20 mM, pH=7.2), and fully dissolve to prepare a 0.2% APE5 solution.

[0053] 2) Take 0.5ml of the oil sample to be tested, and mix the oil sample with the 0.2% APE5 solution according to the volume ratio of oil sample: 0.2% APE5 solution = 1:2.

[0054] 3) Shake for about 1 minute after mixing, so that the oil sample and 0.2% APE5 solution are fully mixed evenly, and then stand for 2 minutes to separate the oil phase and the water phase;

[0055] 4) Take 100 μL of the lower aqueous phase and drop it on the sample hole of the capsaicin quantum dot immunochromatography detection card, and react for 5 minutes;

[0056] 5) Finally, use a quantum dot reader to detect the fluorescence values of the T-line and C-line of the card, bring it into the capsaicin quantitative standard curve built into the instrument, and calculate the capsaicin content in the sample.

[0057] 6) The linear detection range of the method ...

Embodiment 3

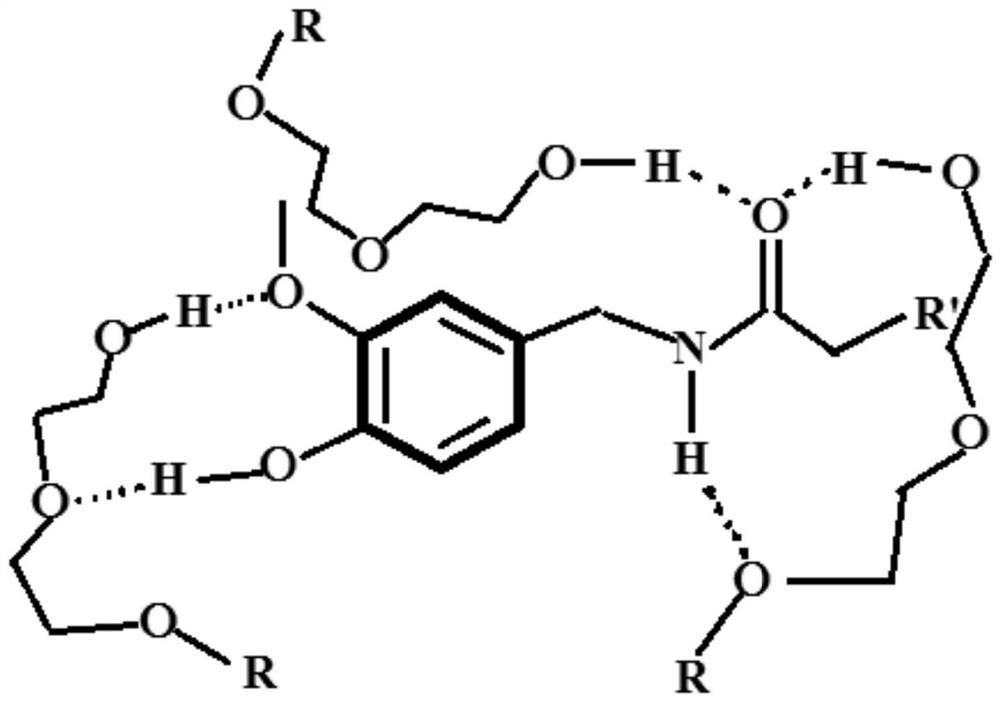

[0059] 1) Take 1 g of methyl β-cyclodextrin reagent, add 100 mL of deionized water, and fully dissolve to prepare a 1% methyl β-cyclodextrin solution.

[0060] 2) Take 0.5ml of the oil sample to be tested, and mix the oil sample with 1% β-cyclodextrin solution according to the volume ratio of oil sample: 1% methyl β-cyclodextrin = 1:2.

[0061] 3) Shake for about 1 minute after mixing, so that the oil sample and 1% methyl β-cyclodextrin solution are fully mixed evenly, and then stand for 2 minutes to separate the oil phase and the water phase;

[0062] 4) Take 100 μL of the lower aqueous phase and drop it on the sample well of the capsaicin total amount time-resolved fluorescence immunochromatography detection card (capable of simultaneously detecting capsaicin, dihydrocapsaicin, and synthetic capsaicin), and react for 5 minutes;

[0063] 5) Finally, use a time-resolved fluorescence detection card reader to detect the fluorescence values of the T-line and C-line of the card,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com