A kind of intelligent control method and control system of inner layer AOI process

A technology of control method and control system, which is applied in the field of intelligent control method and control system of the inner layer AOI process, can solve the problems of less filtering of false points, low accuracy rate of manual maintenance, high error rate, etc., and achieve production automation and management Intelligent, reduce manpower allocation and labor intensity, and realize the effect of automatic distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

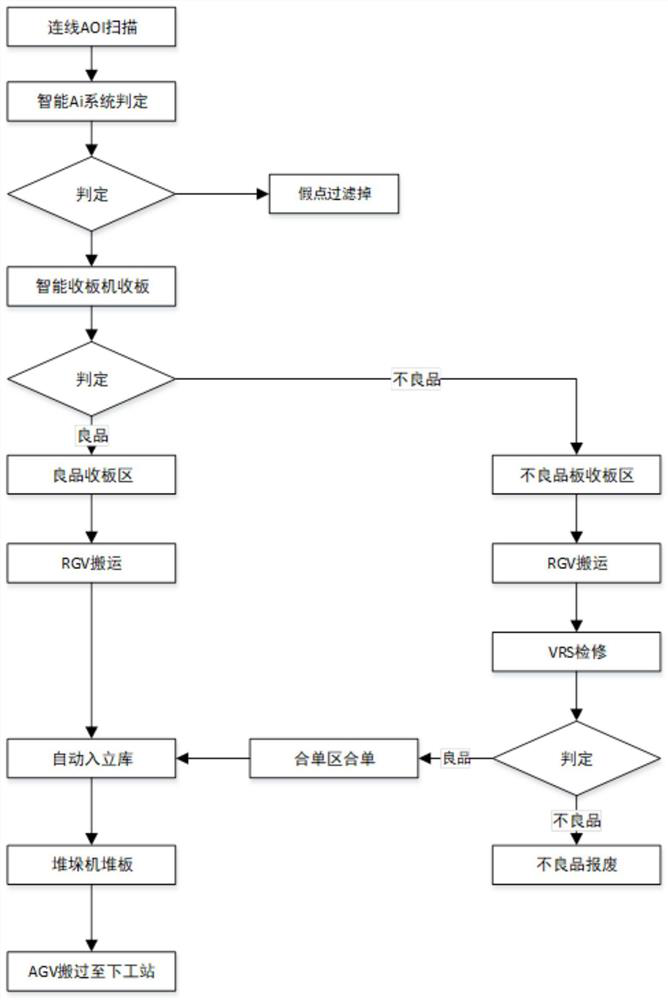

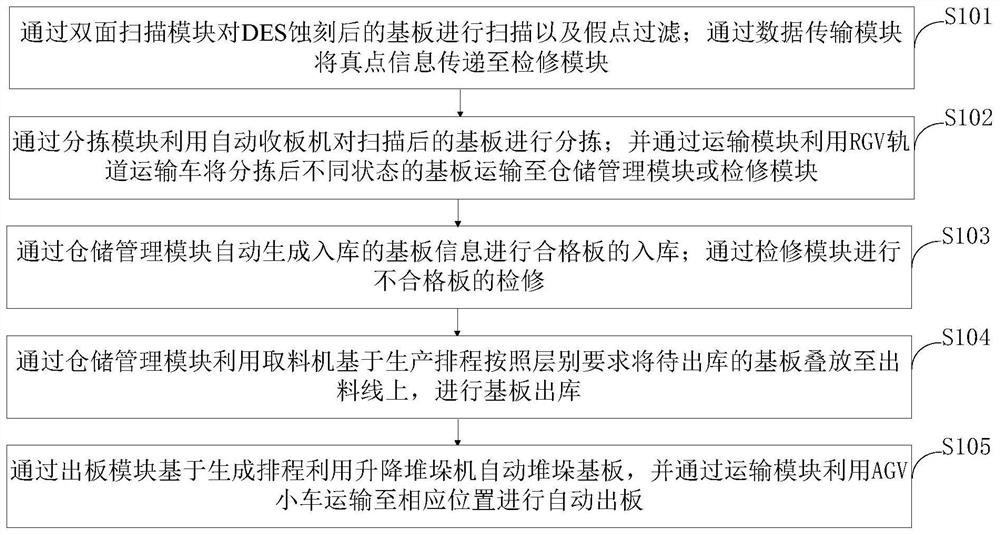

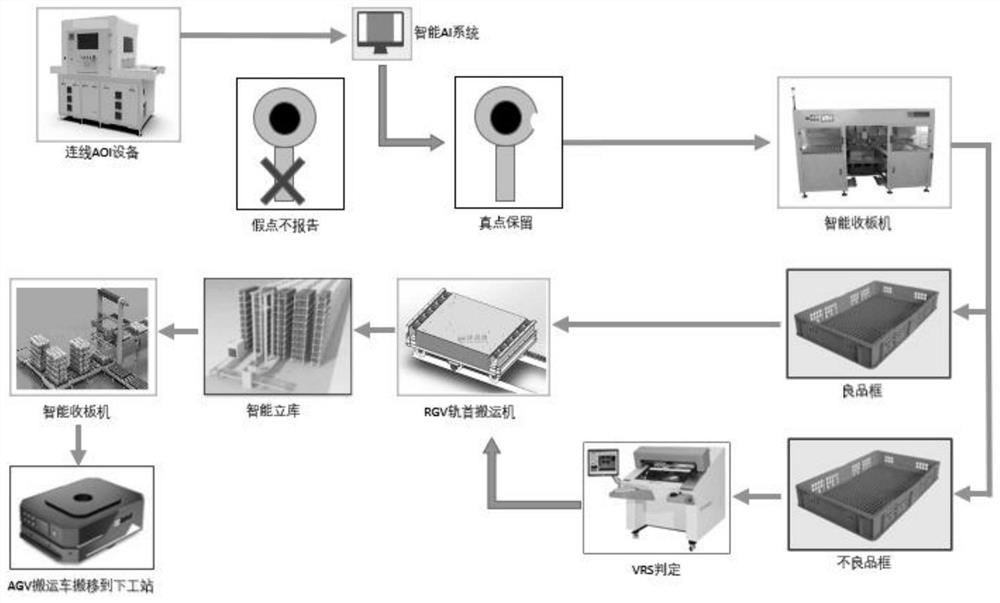

[0109]The inner layer intelligent connection AOI detection system includes online AOI machine (double-sided simultaneous scanning), intelligent solar plate turning machine, automatic plate receiving machine, intelligent temporary storage rack, RGV trolley, VRS maintenance station, intelligent vertical storage system, conveyor Line body, AGV trolley and elevator and other equipment (Table 1), connected to DES etching line, AOI scanning, VRS maintenance station, intelligent vertical warehouse and browning line and other stations ( figure 2 ), after realizing DES etching, the production boards are scanned on both sides online and sorted at the automatic board receiving machine. The sorting system of the receiving machine and the intelligent vertical warehouse matching system realize the intelligent production management through the established logic judgment.

[0110] Table 1 Intelligent design of inner layer AOI process

[0111]

[0112]

[0113] figure 2 The online AO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com