Printing device and manufacturing method of high-precision large-stretching OLED array based on island bridge type structure

A bridge structure, high-precision technology, applied in printing devices, printing, typewriters, etc., can solve problems such as restricting product ductility, flexibility and application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

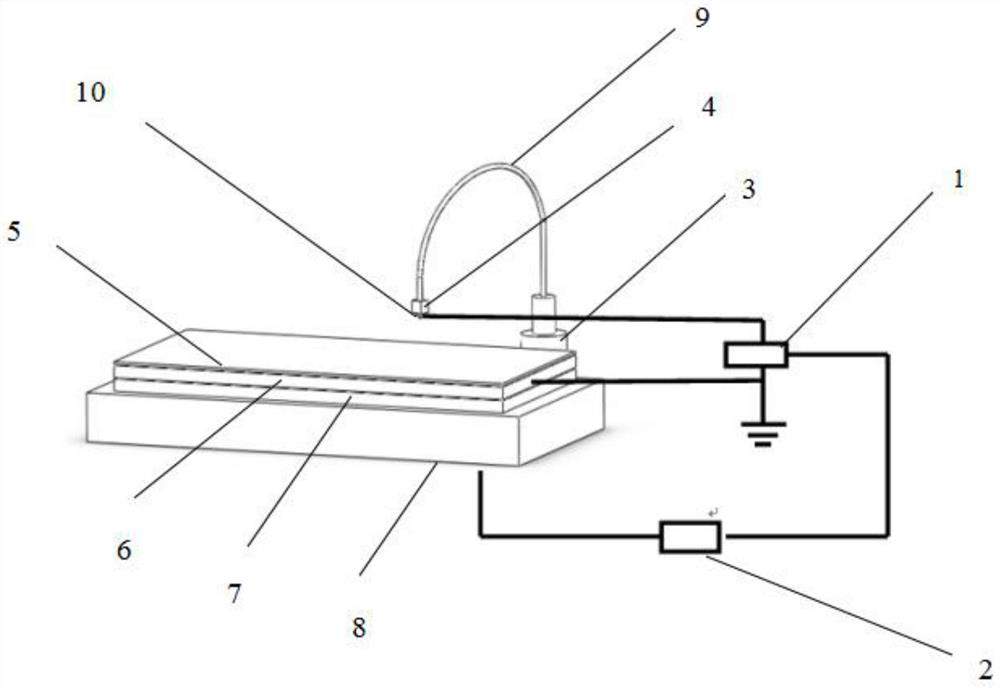

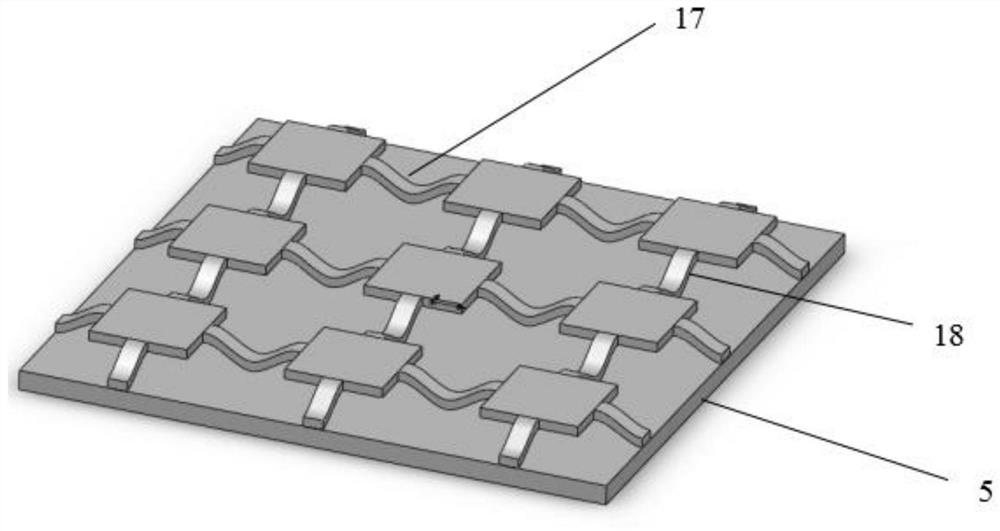

[0031] (1) First, through the figure 1 device, inject polyvinyl alcohol support material into the liquid supply device 4, and print out such as Figure 4 The support material for the base layer 23 of the OLED is shown.

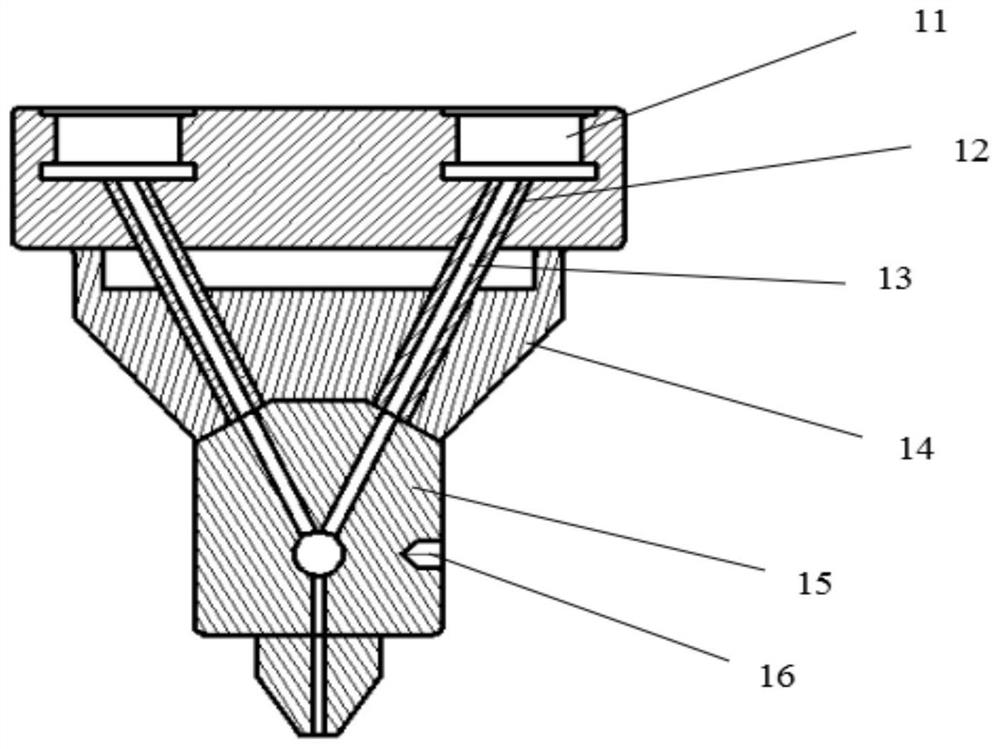

[0032] (2) Then the nozzle selects the 200 μm specification, adjusts the height of the nozzle to keep the distance between the height of the nozzle and the substrate 5 at 500 μm, and injects the graphene-modified conductive silver colloid solution in the liquid supply device 4, wherein the graphene content is 0.07%. , turn on the flow pump to supply liquid at a given rate. At the same time, the high-voltage power supply 1 is turned on to output pulse voltage, the modulation voltage is 2.2kv, the frequency is 50HZ, and the speed of the displacement platform 8 is 5mm / s. The temperature of the heating plate 7 is maintained at 150°C. The five-axis displacement platform is controlled by the computer control system to translate to the predetermined position along...

example 2

[0038] (1) First, through the figure 1 device, inject polyvinyl alcohol support material into the liquid supply device 4, and print out such as Figure 4 The support material for the base layer 23 of the OLED is shown.

[0039] (2) Then the nozzle selects the 225 μm specification, adjusts the nozzle height to keep the distance between the nozzle height and the substrate 5 at 550 μm, and injects the graphene-modified conductive silver colloid solution in the liquid supply device 4, wherein the graphene content is 0.07%. , turn on the flow pump to supply liquid at a given rate. At the same time, the high-voltage power supply 1 is turned on to output pulse voltage, the modulation voltage is 2.6kv, the frequency is 55HZ, and the speed of the displacement platform 8 is 10mm / s. The temperature of the heating plate 7 is maintained at 150°C. The five-axis displacement platform is controlled by the computer control system to translate to the predetermined position along the predeter...

example 3

[0045] (1) First, through the figure 1 device, inject polyvinyl alcohol support material into the liquid supply device 4, and print out such as Figure 4 The support material for the base layer 23 of the OLED is shown.

[0046] (2) Then the nozzle selects the 250 μm specification, adjusts the height of the nozzle to keep the distance between the height of the nozzle and the substrate 5 at 600 μm, and injects the graphene modified conductive silver colloid solution in the liquid supply device 4, wherein the graphene content is 0.07%. , turn on the flow pump to supply liquid at a given rate. At the same time, the high-voltage power supply 1 is turned on to output pulse voltage, the modulation voltage is 2.6kv, the frequency is 60HZ, and the speed of the displacement platform 8 is 15mm / s. The temperature of the heating plate 7 is maintained at 150°C. The five-axis displacement platform is controlled by the computer control system to translate to the predetermined position alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com