Process system and process for preparing chloropinacolone

A technology of a process system and pinatone, which is applied in the field of a process system for preparing monochloropinatone, can solve the problems of affecting yield and purity, and high local concentration, so as to avoid excessive chlorine concentration, reduce chlorine content, and realize The effect of subsequent processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

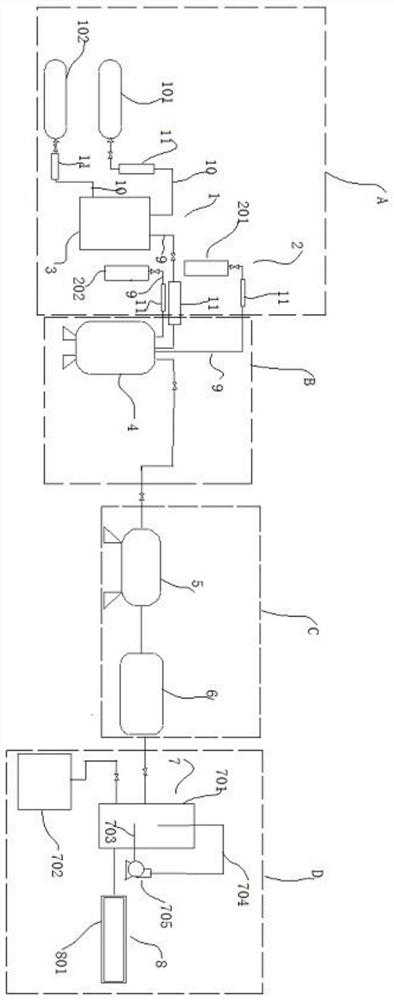

[0046] The process system for preparing chloropinatone comprises:

[0047] The sequentially connected feeding unit A, reaction unit B, purification unit C and post-processing unit D;

[0048] The feeding unit A includes: a gas feeding device 1 and a liquid feeding device 2, the gas feeding device 1 includes a gas mixing tank 3, a first gas storage 101 and a second gas storage 102, the gas mixing tank 3 and The first gas storage 101 and the second gas storage 102 are respectively connected, and the liquid feeding device 2 includes a first liquid storage bottle 201 and a second liquid storage bottle 202;

[0049] The reaction unit B includes a reaction kettle 4, and the reaction kettle 4 is connected to the gas mixing kettle 3, the first liquid storage bottle 201 and the second liquid storage bottle 202 respectively;

[0050] The purification unit C comprises a distillation still 5 and a condenser 6 connected in sequence;

[0051] The post-processing unit D includes a gas abso...

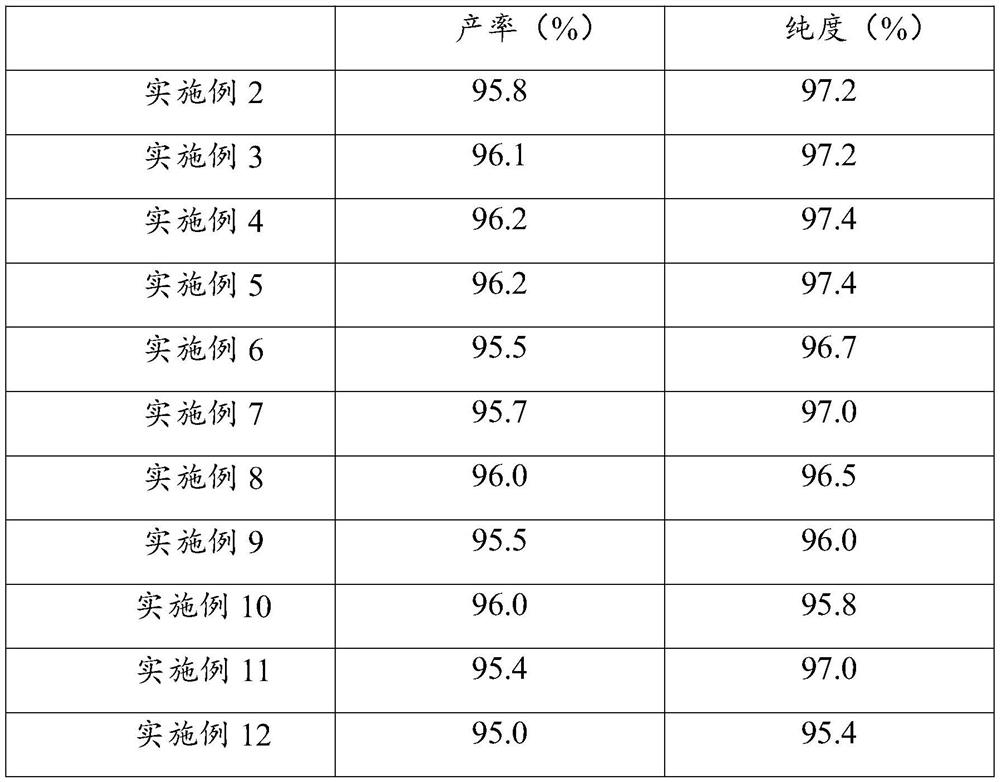

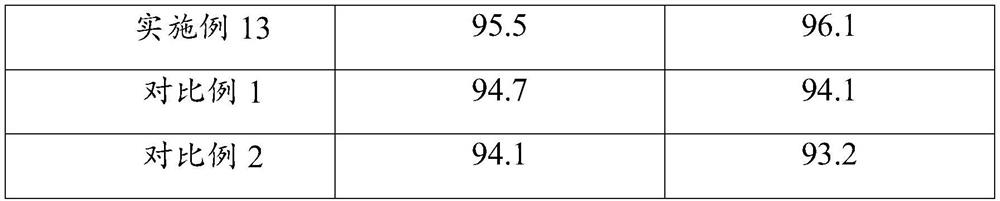

Embodiment 2

[0059] Utilize the technique of embodiment 1 system to prepare monochloropinatone:

[0060] Pinatone is stored in the first liquid storage bottle, methanol is stored in the second liquid storage bottle, chlorine is stored in the first gas storage, and nitrogen is stored in the second gas storage.

[0061] Step S1: add pinacolone and methanol into the reaction kettle, mix and cool down to -3°C (cool the frozen brine that is passed into the jacket of the reaction kettle), and obtain a liquid mixed raw material;

[0062] Step S2: pass chlorine and nitrogen into the gas mixing tank and mix to obtain reaction gas. The flow rate of reaction gas is 50m3 / min, and then feed liquid mixed raw materials. When chlorine reaches the input amount, stop feeding reaction gas. Reaction under the condition of ℃-5℃, after the reaction, the reaction product is obtained;

[0063] In the reaction process, sampling and detection from time to time, when the content of monochloropinatone was 50% of the...

Embodiment 3

[0069] Chloropinatone was prepared according to the steps of Example 2, except that the ratio of the amount of pinacolone to chlorine gas was 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com