Decalcification agent and grease decalcification method

A technology of decalcification agent and grease, applied in the field of decalcification agent, can solve the problem of limited decalcification efficiency, and achieve the effect of improving dynamic wetting ability, reducing cost, simple and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0050] This embodiment provides a method for decalcifying grease. The decalcifying agent in Example 1 is selected, and the waste grease from kitchen waste is used as the grease sample to be decalcified, including the following steps:

[0051] (1) Preheat the oil sample and decalcifying agent to 120°C respectively;

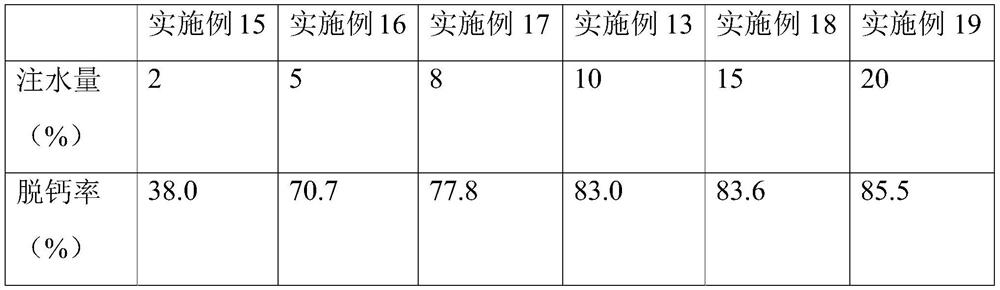

[0052] (2) according to the mol ratio of calcium in the decalcifying agent and the grease sample is 2:1, and the weight of the water in the decalcifying agent is the ratio of 10% of the weight of the grease sample, preheated decalcifying agent and grease The sample is put into the first-level electric desalting tank and mixed at a speed of 3500r / min, and the electric field strength in the first-level electric desalting tank is adjusted to 3000V / cm, and the electric field residence time is 60min so that the calcium complex in the decalcifying agent and the oil sample Combined to form water-soluble substances; after that, the oil-water mixture obtained from the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com