Vacuum control system for atomic layer deposition coating machine

A technology of atomic layer deposition and vacuum control, which is applied in the direction of coating, gaseous chemical plating, metal material coating process, etc., can solve the problem of low vacuum degree of reaction, so as to improve film performance, vacuum degree and use efficiency and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

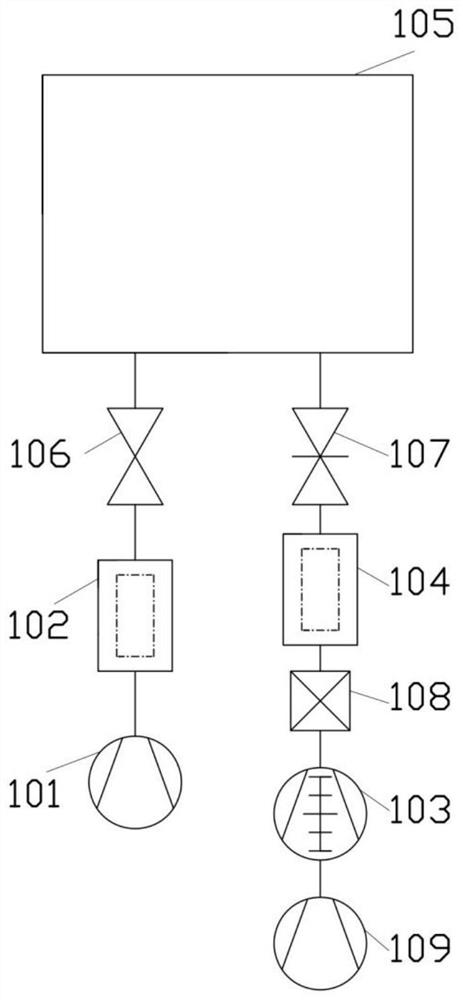

[0072] The present invention is realized by the following technical solutions, such as Figure 1-Figure 4 shown,

[0073] A vacuum control system of an atomic layer deposition coating machine, comprising an A fore-stage vacuum pump 101, a heat trap 102, a coating vacuum chamber 105, a control component 107, a heat trap 104, a control component 108, a molecular pump 103 ; the other end of the molecular pump 103 is connected to the B backstage vacuum pump 109 ; an A valve 106 is arranged between the A heat trap 102 and the coating vacuum chamber 105 .

[0074] During use, the reaction gas, the purge gas, and the metal precursor gas will respectively enter the coating vacuum chamber 105 and be adsorbed to the surface of the coating substrate. The metal precursor contains metal elements, which will cause damage to the molecular pump if it is adsorbed to the rotating bearing of the molecular pump. In order to prevent the metal precursor gas molecules from entering the molecular p...

Embodiment 2

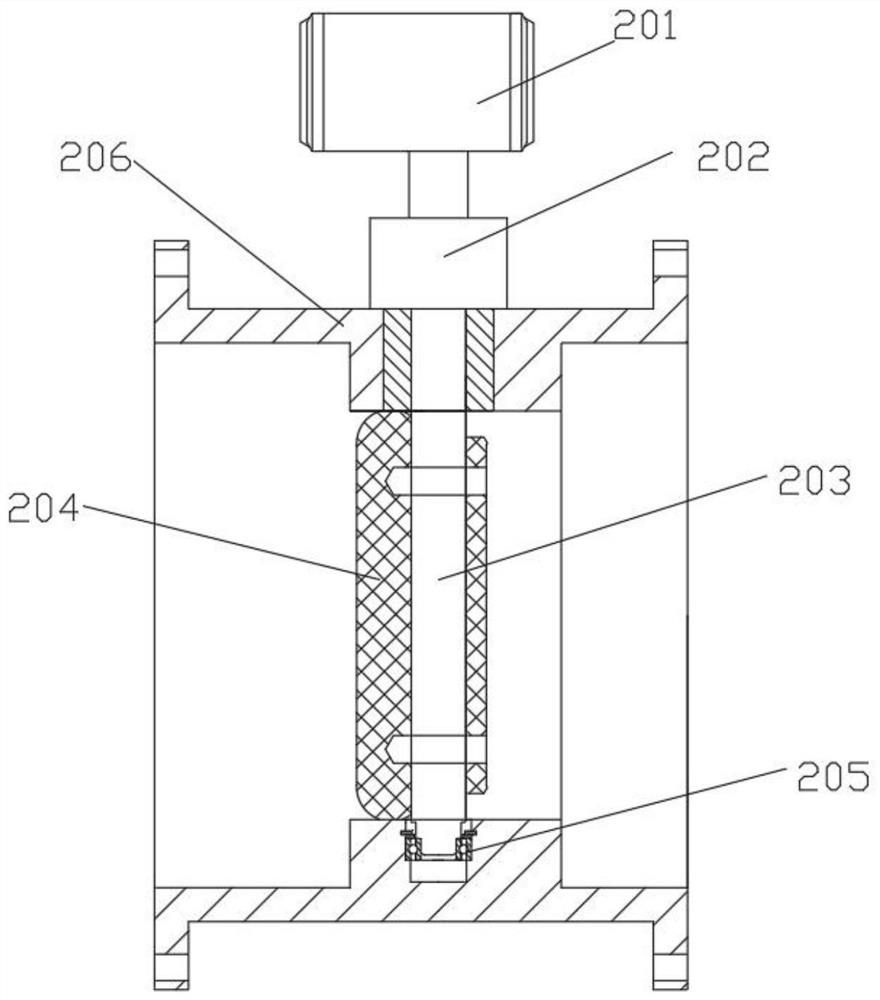

[0077] In this embodiment, the structure of the B control component 108 is further refined on the basis of the above-mentioned first column.

[0078] like figure 2 As shown, the B control assembly 108 includes a drive mechanism 201 disposed outside the pipeline, and an adjustment mechanism connected to the output end of the drive mechanism 201 and disposed in the pipeline.

[0079] The driving mechanism 201 is a rotating mechanism driven by a servo motor or a stepping motor.

[0080] Preferably, the adjustment mechanism includes a magnetic fluid sealing element 202 connected to the output end of the driving mechanism 201 and vacuum connected to the inner wall of the vacuum pipe 206, a rotating shaft 203 disposed in the vacuum pipe and connected to the output end of the magnetic fluid sealing element 202, a mounting A rotary bearing 205 on the inner wall of the vacuum pipe and rotatably connected with the rotary shaft 203 , and a valve plate 204 sleeved on the rotary shaft 20...

Embodiment 3

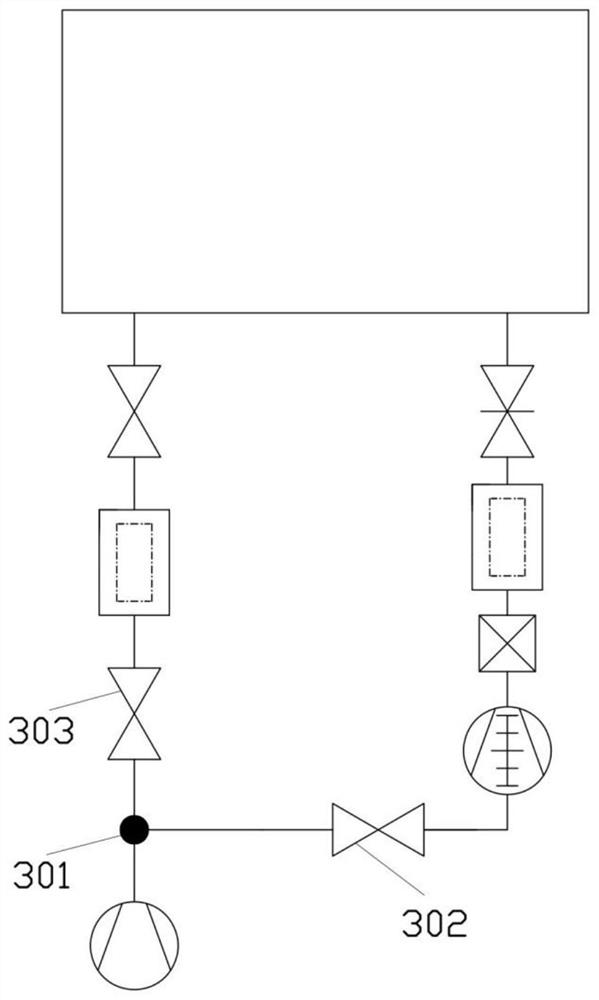

[0084] This embodiment is further optimized on the basis of the above-mentioned embodiment 1 or 2. The specific difference is that only one fore-stage vacuum pump is used in this embodiment, for example, only the A fore-stage vacuum pump 101 is used, and then a tee pipe 301 is used to make A fore-stage vacuum pump 101 is connected to the outlet of A heat trap 102 and the molecular pump 103 at the same time, a D valve 302 is arranged between the A fore-stage vacuum pump 101 and the outlet of the molecular pump 103; a D valve 302 is arranged between the A fore-stage vacuum pump 101 and the outlet of A heat trap 102 There is E valve 303.

[0085]Since the A fore-stage vacuum pump 101 is used to connect the outlet of the molecular pump 103 and the coating vacuum chamber 105 respectively, when using the molecular pump 103 and the A fore-stage vacuum pump 101 to cooperate to achieve vacuum, the connection between the A fore-stage vacuum pump 101 and the A heat trap 102 is The E valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com