Distributed air curtain device for supercritical CO2 boiler

A distributed and supercritical technology, applied in the direction of air induction, outer cover/lining, combustion method, etc., can solve the problems of wind erosion and shortening of the wall, and achieve the effect of avoiding overheating and flexible distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

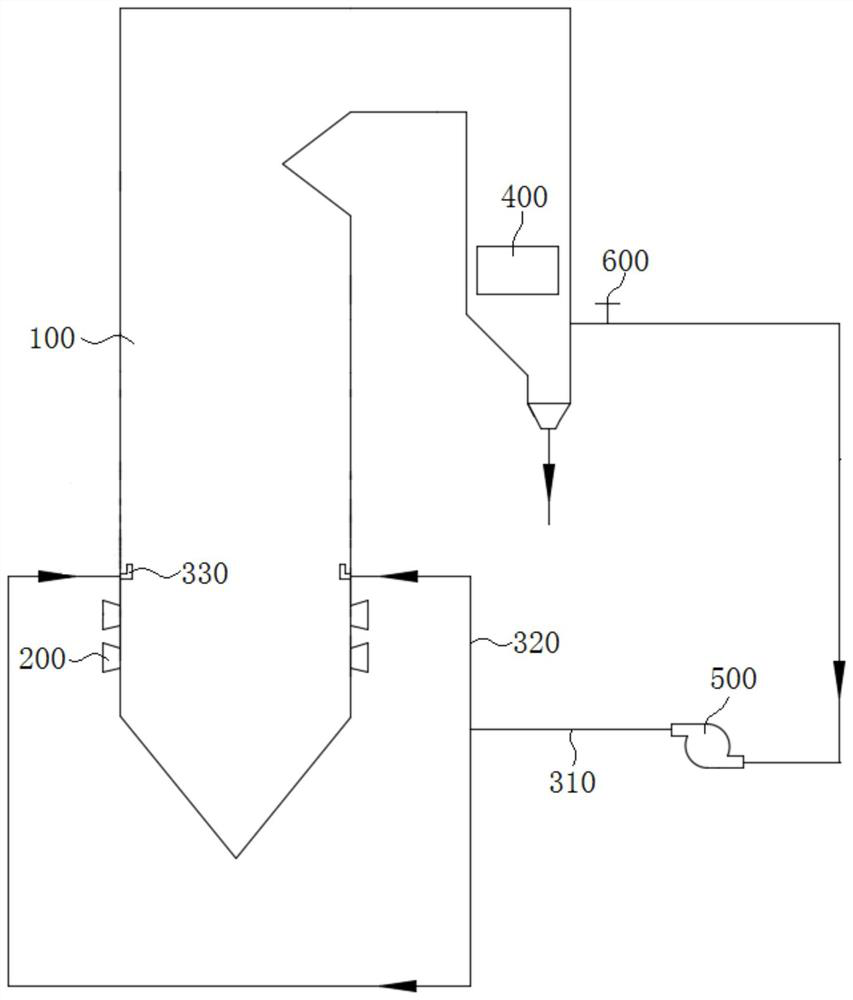

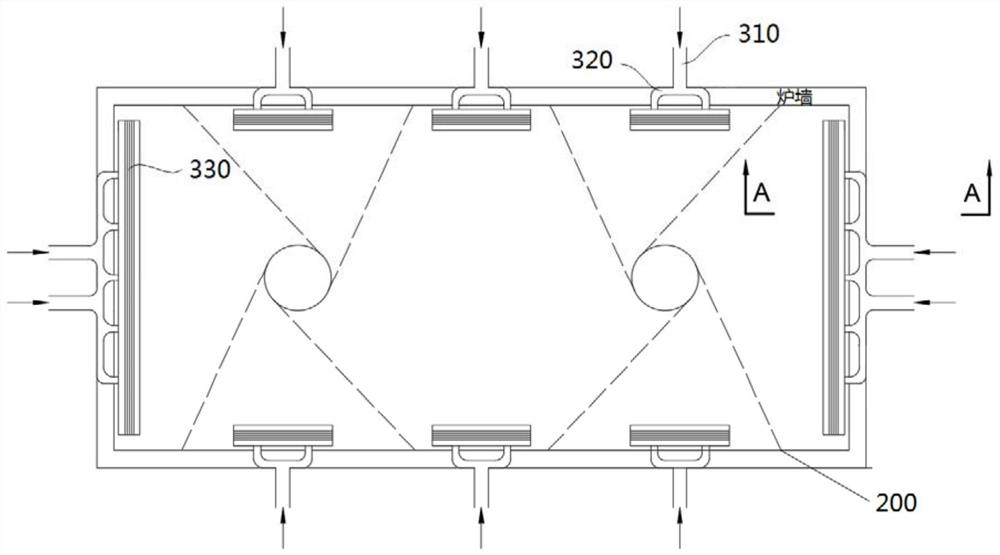

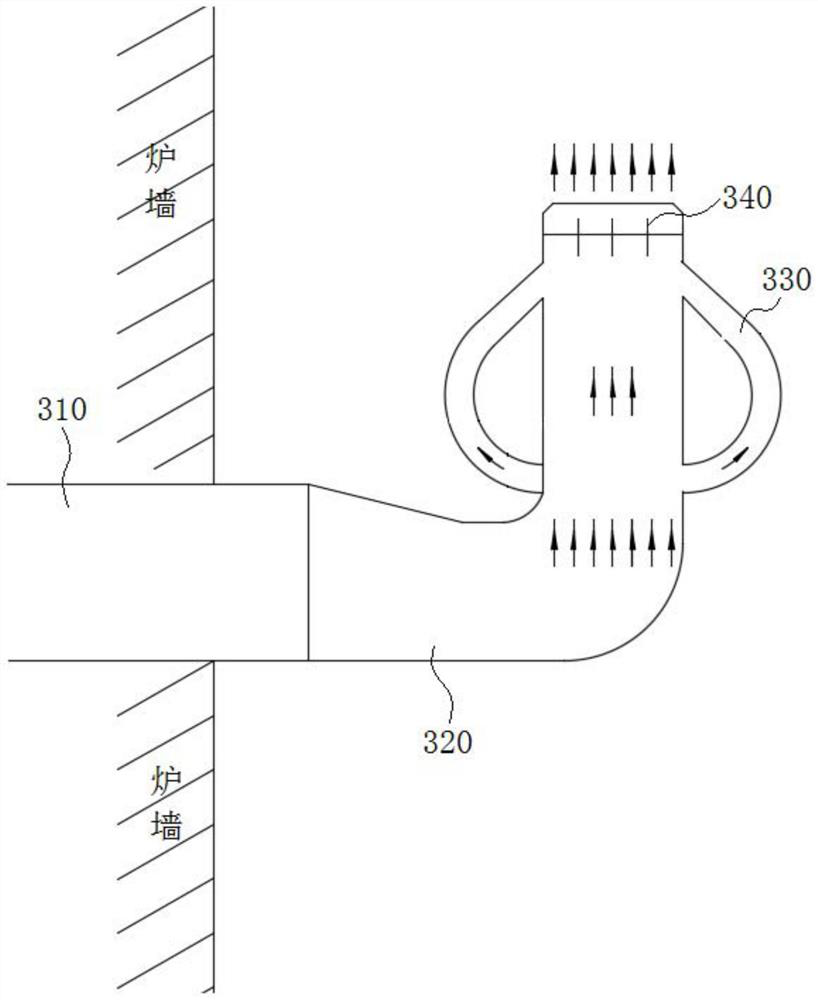

[0040] Such as Figure 1 to Figure 4 As shown, the arrow in the figure indicates the direction of travel of the flue gas, the supercritical CO of the present embodiment 2The distributed air curtain device of the boiler is arranged in the gap between the furnace wall and the water-cooled wall for cooling the water-cooled wall, including: an air induction mechanism, which includes at least one high-speed induced draft fan 500, and the inlet of the high-speed induced draft fan 500 passes through The pipeline is connected to the boiler furnace body 100, and the pipeline is provided with an air intake control valve 600; the high-speed induced draft fan 500 extracts part of the flue gas after the economizer 400; the air injection mechanism 300 includes the main air inlet pipe 310, the airflow flat slit Nozzle 330 and distribution pipe 320, one end of the main air inlet pipe 310 is connected to the outlet of the high-speed induced draft fan 500, and the other end is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com