Semiconductor production control method and system

A production control method and production control technology, applied in the general control system, control/adjustment system, adaptive control, etc., can solve the problems of semiconductor production lines that need to be improved, so as to improve quality and efficiency, increase computing efficiency, and increase computing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It can be known from the background art that the current semiconductor production control methods have limited effects on improving quality and performance.

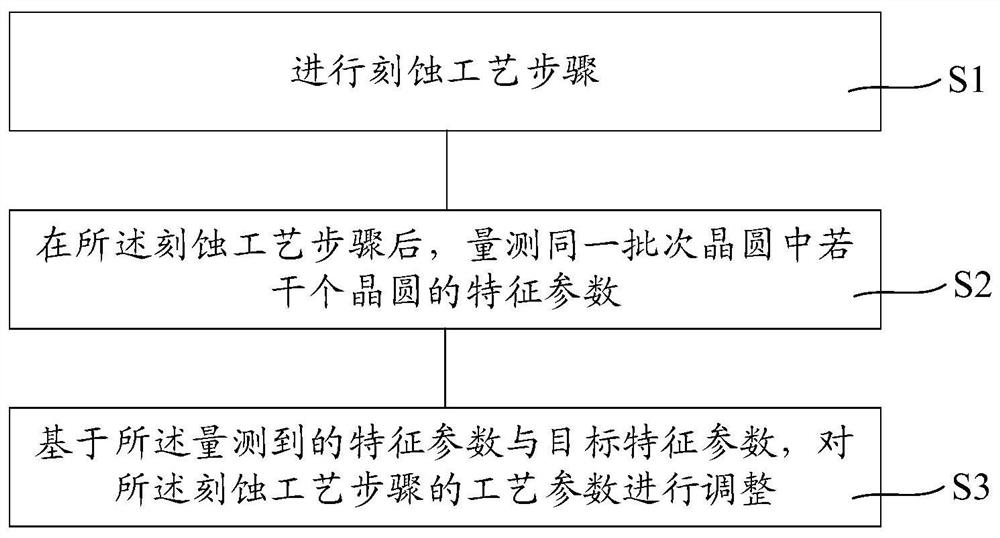

[0028] Current semiconductor control methods are based on measurement results for feedback control. figure 1 It is a schematic flowchart of a semiconductor production control method, refer to figure 1 , the semiconductor production control method includes the following steps: step S1, performing an etching process step; step S2, after the etching process step, measuring the characteristic parameters of several wafers in the same batch of wafers; step S3, based on The measured characteristic parameters and the target characteristic parameters are used to adjust the process parameters of the etching process step.

[0029] However, the above control method is less effective for adjusting the process parameters of the etching process step. The analysis found that the reasons for the limited effect of the above contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com