Dual-purpose tobacco particles, smoking product and preparation method of smoking product

A tobacco granule and dual-purpose technology, which is applied in the fields of tobacco, tobacco processing, and tobacco preparation, can solve the problems of inconvenient use, insufficient smoke volume, and affecting alcohol-soluble experience, etc., and achieve good smoking taste and stable smoking And the effect of good uniformity and novel appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

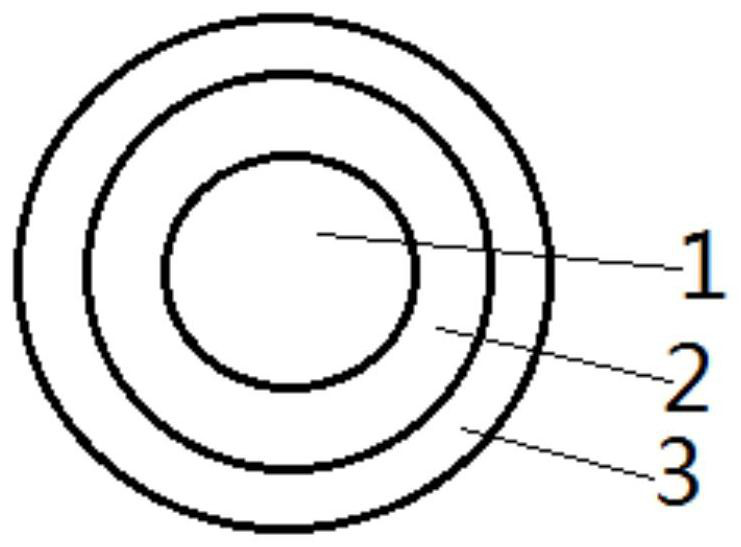

Image

Examples

Embodiment 1

[0042] The preparation method of the dual-purpose tobacco particles of the present embodiment comprises the following steps:

[0043] 1) In parts by mass, take 100 parts of 80-150 mesh tobacco powder, 50 parts of wood pulp fiber, and 10 parts of modified starch and mix evenly; get 10 parts of glycerin, 10 parts of propylene glycol, 5 parts of tobacco extract, and 30 parts of 25% The volume content of ethanol is stirred and mixed evenly; the mixed solution is sprayed on the mixed powder and stirred evenly, shaken and granulated, and dried to obtain 15-30 mesh particles to obtain the core of tobacco particles; 2) 5% corn is prepared by using 60wt% ethanol Protein solution, carry out fluidized bed coating according to dry matter mass ratio 3%, obtain one layer of coated tobacco particles; 3) use hydroxypropyl methylcellulose, according to dry matter ratio 5wt% to the tobacco particles obtained in step 2) Perform secondary coating, dry and sieve to obtain 15-30 mesh dual-purpose t...

Embodiment 2

[0048] The preparation method of the dual-purpose tobacco particles of the present embodiment comprises the following steps:

[0049] 1) In parts by mass, take 100 parts of 100-120 mesh tobacco powder, 30 parts of wood pulp fiber, 20 parts of cane pulp fiber, and 5 parts of cyclodextrin and mix evenly; take 10 parts of glycerin, 20 parts of propylene glycol, and 5 parts of tobacco to extract 35 parts of 10% potassium citrate aqueous solution, stir and mix with it evenly; spray the mixed solution in the mixed powder and stir evenly, rotate and extrude into strips, shake and granulate again, dry and take 15-25 mesh granules. Tobacco granule inner core; 2) use paraffin wax and stearic acid hot-melt coating with a mass ratio of 1:1, and the quality of the coating layer is 3% of the inner core granule mass to obtain a layer of coated tobacco granules; 3) use 5% polydimensional The ketone aqueous solution is used to coat the tobacco particles obtained in step 2) according to a dry m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com