Refining agent for ethylene glycol hydrofining and preparation method thereof

A hydrogenation refining and refining technology, which is applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problem of low UV transmittance and achieve high UV transmittance and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

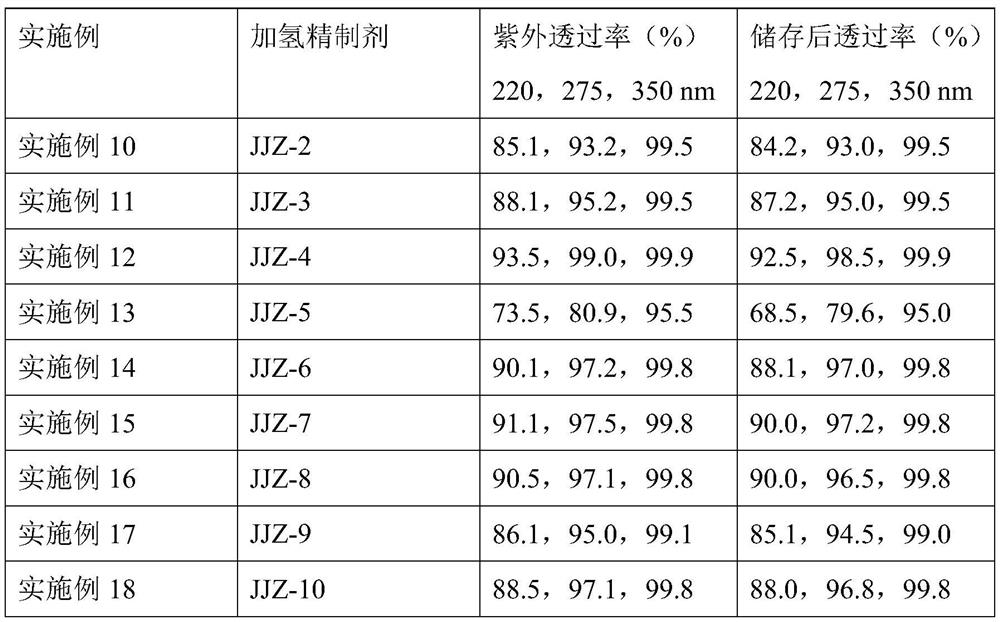

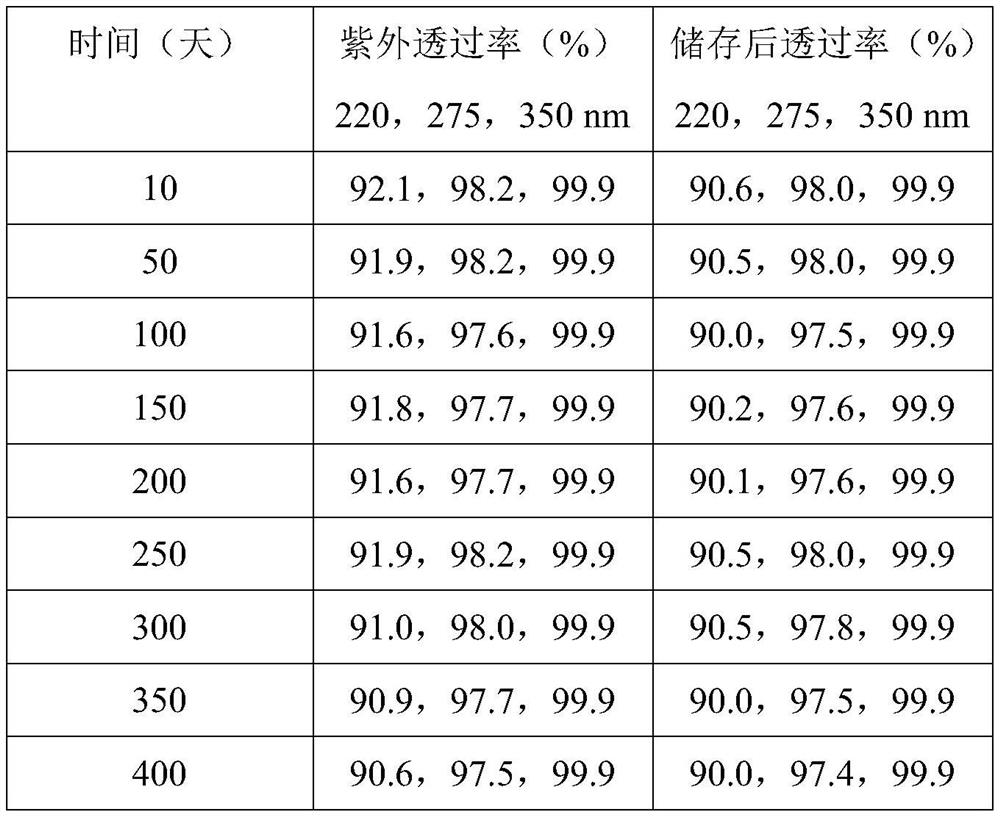

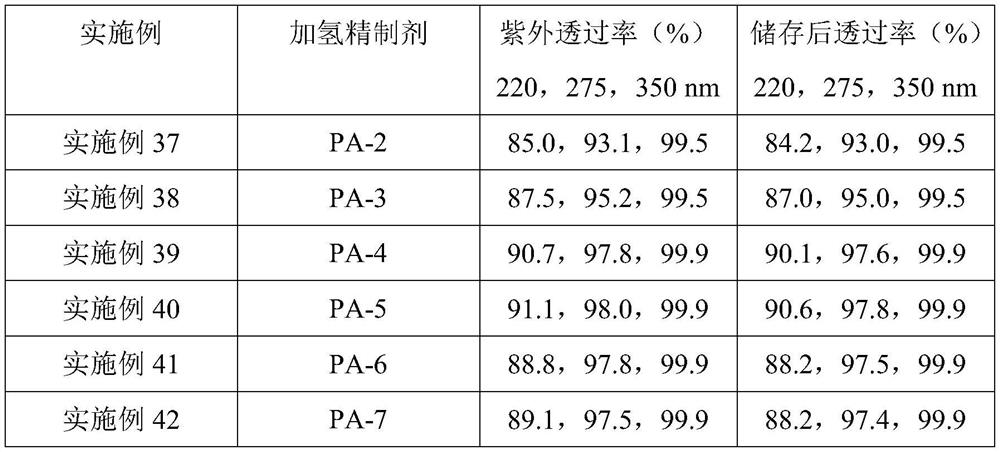

Examples

Embodiment 1

[0094] In a 500mL beaker, add 29.4g dry macroporous strongly acidic cation exchange resin Amberlyst-15 (exchange capacity is 5.2meq / g), 200g deionized water, after swelling for 5h, add 20mL palladium nitrate aqueous solution containing 1.31g palladium nitrate, Stir, heat up to 50°C, ion exchange for 5 hours, filter, wash the filtrate 10 times with deionized water, redisperse in 200mL water, heat to 75°C, and flow hydrogen at a flow rate of 30mL / min for reduction, after 5h Finished, filtered, and the obtained solid was dried in an oven at 110 degrees for 24 hours to obtain a hydrorefined preparation JJZ-1 with a structural formula of Pd-Amberlyst-15, wherein the mass fraction of Pd was 2.0, and the mass fraction of Amberlyst-15 was 98.0 .

Embodiment 2

[0096] The preparation method of the hydrofinishing preparation is the same as [Example 1], except that the amount of the carrier used is 29.9 g, the metal salt is 0.33 g of palladium nitrate, and the obtained hydrofinishing preparation is JJZ-2, and the structural formula is Pd-Amberlyst -15, wherein the mass fraction of Pd is 0.5, and the mass fraction of Amberlyst-15 is 99.5.

Embodiment 3

[0098] The preparation method of the hydrofinishing preparation is the same as [Example 1], except that the amount of the carrier used is 29.7g, the metal salt is 0.66g of palladium nitrate, and the obtained hydrofinishing preparation is JJZ-3, and the structural formula is Pd-Amberlyst -15, wherein the mass fraction of Pd is 1.0, and the mass fraction of Amberlyst-15 is 99.0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com