Method for recovering terephthalate from waste PET

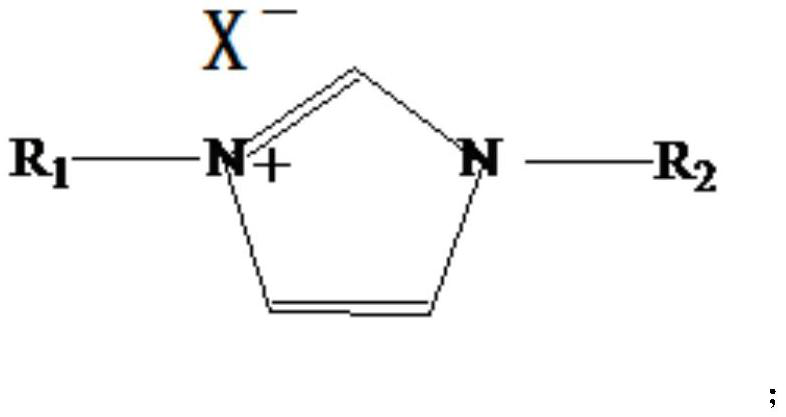

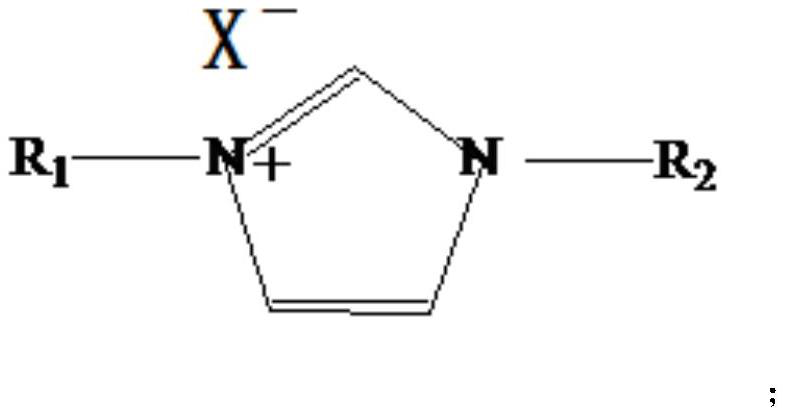

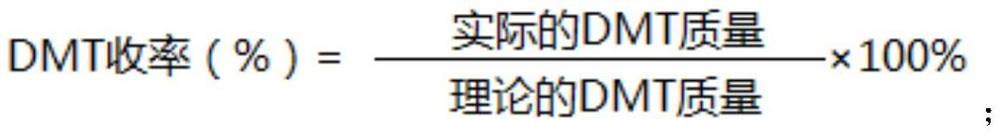

A technology of terephthalate and terephthalic acid, which is applied in the field of terephthalate recovery, can solve the problems of slow reaction speed and low product yield, achieve short reaction time, low catalyst consumption, DMT The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The reaction was carried out in a 500ml titanium autoclave equipped with a magnetic stirrer, a gas delivery tube, a reflux condenser, a thermocouple, and a rupture disc, with a stirring speed of 400 rpm and electric heating. The reaction steps are as follows:

[0032] 1) Weigh 10 g of waste polyester PET, 3 g of terephthalic acid, 80 g of methanol, and 0.15 g of 1,3-dimethyl imidazolium bromide, mix them evenly, add them to the autoclave, and seal them.

[0033] 2) Add 10.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0034] 3) The pressure was released to normal pressure, then purged with nitrogen for 3 times, the intake switch was closed, and the stirrer was started, the stirring rate was 400rpm, the temperature was raised to 280°C, and the pressure was kept at 10.0MPa, and the reaction was carried out at 280°C for 60min.

[0035] 4) After the reaction is completed, s...

Embodiment 2

[0038] The reaction was carried out in a 500ml titanium autoclave equipped with a magnetic stirrer, a gas delivery tube, a reflux condenser, a thermocouple, and a rupture disc, with a stirring speed of 400 rpm and electric heating. The reaction steps are as follows:

[0039] 1) Weigh 10 g of waste polyester PET, 1 g of terephthalic acid, 80 g of methanol, and 0.15 g of 1,3-dimethylimidazolium bromide, mix them evenly, add them to the autoclave, and seal them.

[0040] 2) Add 10.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0041] 3) The pressure was released to normal pressure, then purged with nitrogen for 3 times, the intake switch was closed, and the stirrer was started, the stirring rate was 400rpm, the temperature was raised to 280°C, and the pressure was kept at 10.0MPa, and the reaction was carried out at 280°C for 60min.

[0042] 4) After the reaction is completed, sw...

Embodiment 3

[0045] The reaction was carried out in a 500ml titanium autoclave equipped with a magnetic stirrer, a gas delivery tube, a reflux condenser, a thermocouple, and a rupture disc, with a stirring speed of 400 rpm and electric heating. The reaction steps are as follows:

[0046] 1) Weigh 10 g of waste polyester PET, 6 g of terephthalic acid, 80 g of methanol, and 0.15 g of 1,3-dimethyl imidazolium bromide, mix them evenly, add them to the autoclave, and seal them.

[0047]2) Add 10.0MPa nitrogen to carry out the airtight test for 30 minutes, and the pressure drop within 30 minutes is not more than 0.1MPa, which is qualified.

[0048] 3) The pressure was released to normal pressure, then purged with nitrogen for 3 times, the intake switch was closed, and the stirrer was started, the stirring rate was 400rpm, the temperature was raised to 280°C, and the pressure was kept at 10.0MPa, and the reaction was carried out at 280°C for 60min.

[0049] 4) After the reaction is completed, sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com